GEFERTEC, the German developer and provider of 3DMP metal 3D printers and technology, has partnered with Linde Group, a Munich-based chemical company, to investigate process gas and oxygen within metal additive manufacturing.

Gases significantly influence the material properties of an additively manufactured part. Within the chamber of a 3D printer, the gas composition affects the weight, texture, and overall parameters of a component.

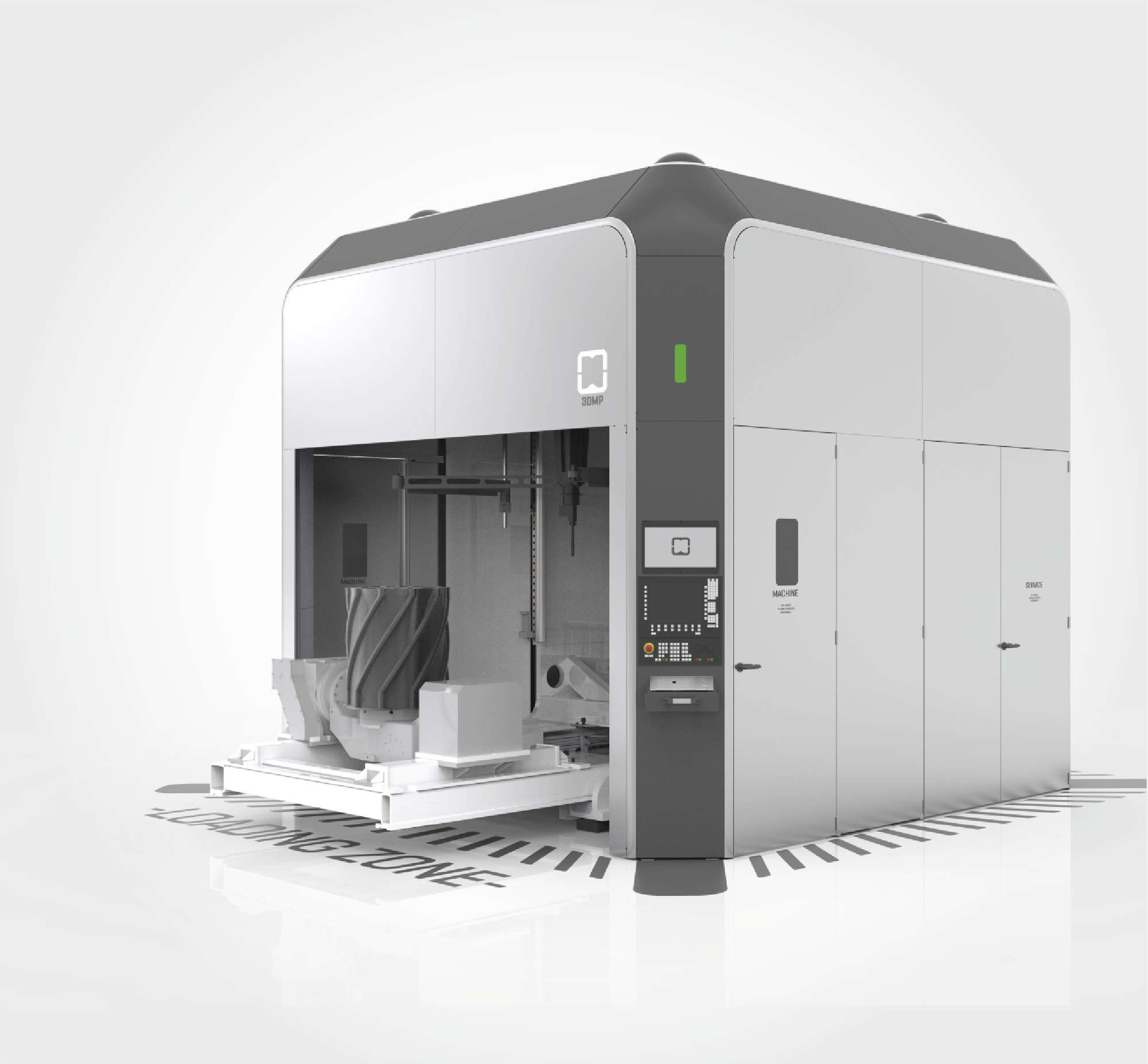

GEFERTEC’s 3DMP technology, which incorporates wire-arc melting based metal additive manufacturing to create near-net-shape components, heavily relies on the process gases.

3DMP technology

According to GEFERTEC, 3DMP technology promises to eradicate waste with “nearly 100% material utilization,” and cost savings of “up to 60% versus conventional manufacturing.”

The company has developed four 3DMP machines in its portfolio. This includes the arc603, a 3-axis machine capable of creating components up to 3 m³, with a maximum mass of 3000kg and the arc605, a 5-axis machine with a maximum capacity of up to 0.8 m³ and 500 kg mass.

GEFERTEC has also developed the arc405, a 5-axis, 0.06 m³ capabilities and a maximum mass of 200 kg, and the arc403, the 3-axis machine which has been recently installed by Airbus.

Investigating gas and oxygen for 3D printing

Within this research collaboration, MT Aerospace AG, a German aerospace company, will perform mechanical tests of 3D printed parts from 3DMP. The fabrication of such parts will take place at the additive manufacturing laboratory of Fraunhofer IGCV, where GEFERTEC’s machinery is installed. Fraunhofer is the fourth co-operation partner of this project.

Following these processes, the influence of welding parameters and process gas on the parts will be examined. The ultimate goal of this project is the production of larger parts at high production speed made of the titanium alloy Ti6Al4V. If successful, these 3D printed parts will meet the quality requirements for the aerospace industry.

Who has made the most significant contribution to the aerospace sector? Nominate for the upcoming 3D Printing Industry Awards 2019.

Also, for the updates on 3D printing in the aerospace sector, subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Looking for a fresh start this year? Visit 3D Printing Jobs to commence your career in additive manufacturing.

Featured image shows the GEFERTEC 3DMP additive manufacturing process. Photo via GEFERTEC.