Sliced is 3D Printing Industry’s digest of all the latest additive manufacturing news features from around the world. Today’s edition includes award winners, business deals and cutting-edge research developments from both well-known and upcoming institutions and companies.

Metal additive goes big in WAAM and ASME awards

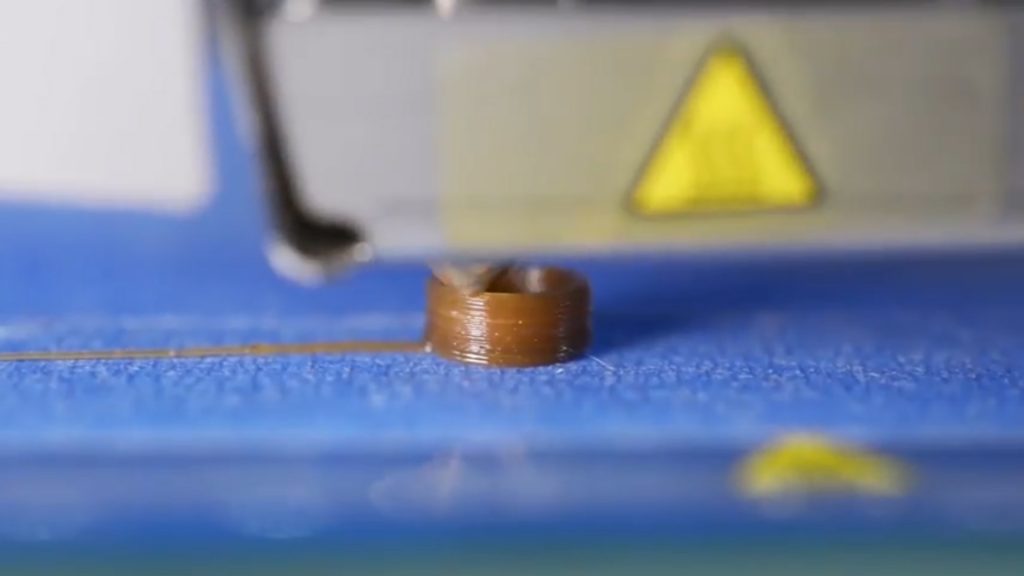

Committed to pushing methods of metal 3D printing beyond their boundaries, Germany’s GEFERTEC has developed a trademark 3DMP for large-scale wire-arc additive manufacturing. A recent clip published on the company’s YouTube page shows the 3DMP process making a fully dense metal component. In another clip it is also seen making propeller parts, not dissimilar to Damen Shipyard’s WAAMpeller.

Siemens 3D printed gas turbine blades, that previously won 3D printing use case of the year at the first annual 3D Printing Industry awards, have now also been acknowledged by the American Society of Mechanical Engineers (ASME). ASME president Charla K. Wise comments, “The 3D printed turbine blade places Siemens at the forefront of a technology trend that is spurring a global revolution in product design and production,”

“Mechanical Engineering magazine is pleased to present one of the five Emerging Technology Awards to a leader in manufacturing, and we thank the design team on the 3D printed blade for advancing technology excellence.”

Re-imaging the future of 3D printing

The field of quantum dots, for tracking and security purposes in 3D printed objects, has gained new research from the Karlsruher Institute Für Technologie (KIT). In a paper published in Advanced Materials Technologies, authors explore the fluorescence of the dots under thin layers of polymer as an alternative to conventional surface-only approaches.

Adding to a popular paper published in November 2017, a team at TU Delft has demonstrated how origami-inspired 4D printing technology can be used to make versatile, self-folding lattices.

An inspired use case from the Institut für Holztechnologie Dresden is using FDM technology to create better spring suspension systems in upholster furniture.

Nano Dimension has published a new case study demonstrating how the DragonFly 2020 can be used to 3D print electromagnets.

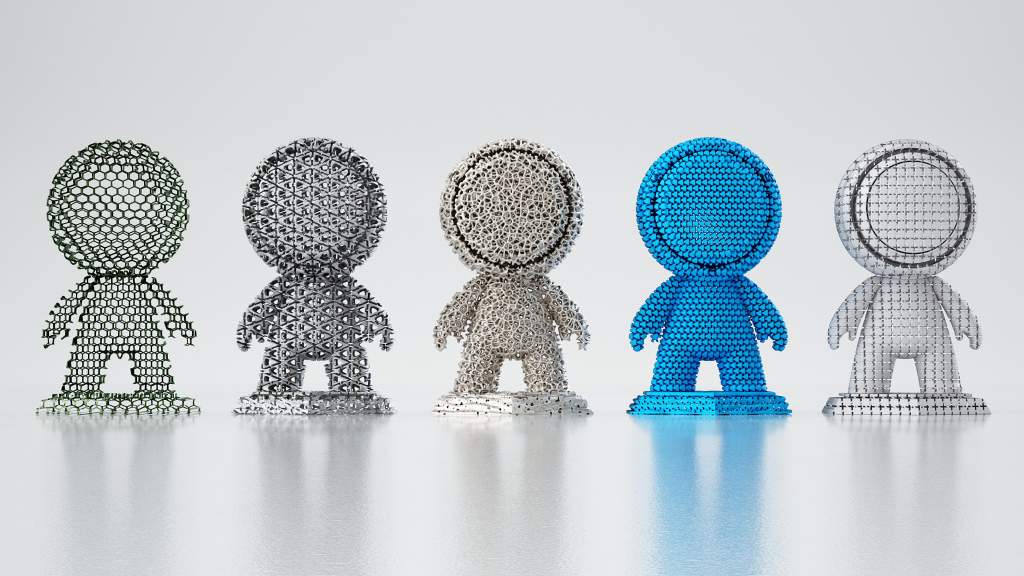

Allegorithmic have introduced next-level product previews for 3D printable models to its Substance Source program. In the official announcement, Allegorithmic Product manager and CMF Designer Nicolas Paulhac states, “This winter, Substance Source expands with more than 50 tweakable materials dedicated to 3D printing. We have mimicked the visual characteristics of 10 additive manufacturing technologies to help artists previsualize the results of 3D printing in photorealistic ways.”

And 3D printing is also used to make smart, private window prototypes by Daniel Wolfe and K. W. Goossen at the University of Delaware’s Department of Electrical and Computer Engineering.

Gold standard partnerships

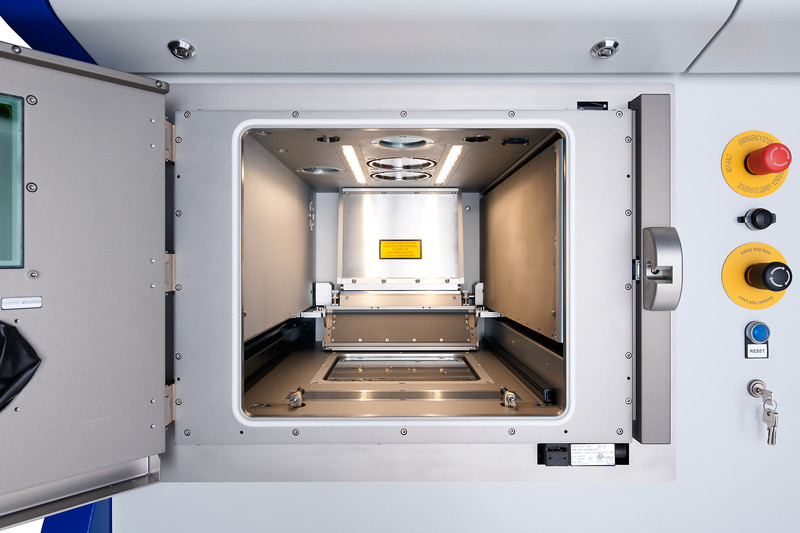

Italian precision mechanics and rapid prototyping company Zare has become the latest customer of SLM Solutions’ 280 2.0 system. The machine’s 280 x 280 x 365 mm³ build chamber was a key determiner in the acquisition. Andrea Pasquali, co-owner of Zare, comments, “If you have a larger vertical expansion available, then that component in the machine can be aligned better and the number of necessary support elements reduced, which also reduces unwanted tension inside the component.”

Dassault Systèmes and management consultant company Accenture have a new partner in Bouygues Construction company. Under the new initiative, Bouygues Construction will leverage its partners’ expertise to enhance is PLM system using the 3DEXPERIENCE platform. Christian Nibourel, Accenture’s Country Managing Director for France and Benelux, says, “By using the latest digital technologies to enable the simultaneous collaboration of the whole ecosystem of a construction project, Bouygues Construction will have better control of costs and deadlines while minimising risks and adapting to subsequent changes in customers’ needs and in the standards in force.”

3D technology hardware and service reseller Europac 3D has become a Gold Partner of 3D scanner provider Artec 3D. The new status makes Europac 3D an accredited distributor and adviser for Artec products including the Eva, Eva Lite, Space Spider and Leo.

UK additive manufacturing company has also attained gold partnership status this month. Adding its name to North America’s Advanced Digital Technology (ADT) Foundation, Renishaw will share it digital expertise with specialists working in the field of head and neck reconstruction.

The Youngstown Business Incubator held an opening ceremony for its 3D printing startup campus in Ohio this week.

Over in Japan, Sojitz Corporation and Koiwai Co., Ltd. have established the JAMPT Corporation for mass production and resale of 3D printed products and powdered materials.

For the first time in a longstanding partnership with the company, rolling element bearings manufacturer Schaeffler is expanding its additive manufacturing facility with a DMG Mori LASERTEC 65 3D hybrid system.

And large-format digital printing company Pictographics has gone 3D with the addition of a Massivit 1800 additive manufacturing system.

More materials, more possibilities

A 3D printed stainless steel reactor has been used to recycle Teflon waste product as a solid material. The specific design of the reactor enabled researchers to utilize stainless steel for “fast heat transfer and high pressure resistance,” turning waste matter into new material in less than 2 mins. Full results of the study are published online here.

Also taken an environmentally friendly approach, using a biomass-derived polymer, Russian researchers have managed to create a carbon-neutral, repeatably recyclable filament for use in FDM 3D printers.

A spaghetti-like hydrogel from the University of Princeton gives news potential to the use of 3D printing for wound care. As stated in the project’s introduction, “Given the importance of hydrogels in several applications, including tissue engineering, drug delivery, surgical adhesives, and 3D bioprinting, there are benefits to be achieved by exploring and developing simple methods for producing hydrogels, beyond the

synthetic and physical approaches that currently exist.”

Life-saving applications

In many ways, this week has also seemed a little like medical 3D printing season.

Lima Corporate’s proprietary Trabecular Titanium material has used to make a 3D printed shoulder replacement for a patient in Croatia.

A Zurich project developing custom-3D printed, drug coated airway stents has been given a CHF 2,341,446 ($2.37 million USD) grant by the Swiss National Science Foundation.

Incorporating 3D bioprinting, Researchers at Case Western Reserve University have published a review of “how organic components can be used for all facets of robot development.”

Supported by the U.S. National Institutes of Health Penn State engineers have developed a structural framework for growing living tissue using an off-the-shelf 3D printer.

Guru Nanak Dev Engineering College has been granted a substantial sum of money by the Indian government to focus on the development of 3D printed, biocompatible implants.

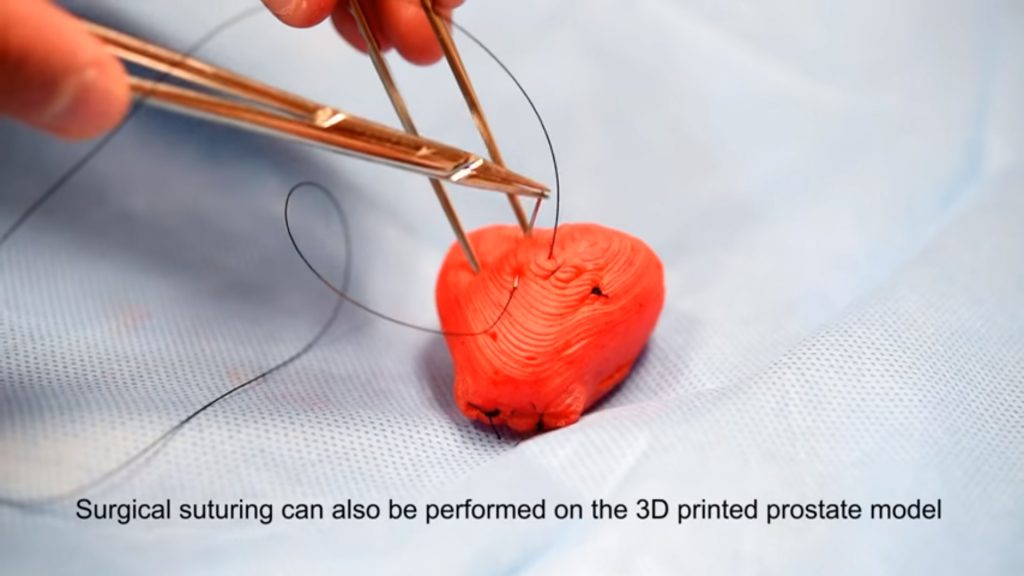

And the University of Minnesota has 3D printed lifelike artificial organ models that mimic the exact anatomical structure, mechanical properties, and look and feel of real organs.

That’s all for this week’s Sliced 3D printing news digest but, if you’d like these updates delivered directly to your inbox subscribe to the free 3D Printing Industry newsletter here. You can also follow us on Twitter, and like us on Facebook.

Don’t forget to make your nomination for the second annual 3D Printing Industry Awards too.

Featured image shows Sliced logo over GEFERTEC’s wire arc additive manufacturing process. Photo via GEFERTEC