Lima Corporate, the Italian company that pioneered the development of 3D printed titanium trabecular implants, is partnering with Materialise, one of the leading providers of medical (and non-medical) 3D software and 3D printing services, to offer patient-specific, 3D printed surgical guides for partial knee implants.

Lima will, thus, offer the Materialise-powered surgical knee guide system in the European Economic Area (EEA) region and Switzerland. “Materialise first pioneered medical image based guide technology, including solutions for the knee, as part of our company-wide mission to realize a better and healthier world through meaningful applications of 3D printing,” said Jeroen Dille, Director of Materialise’s Clinical Unit. “Through this collaboration with Lima,” he added, “orthopedic surgeons will be able to benefit from the advantages that 3D printing can offer in the planning and execution of partial knee arthroplasty.”

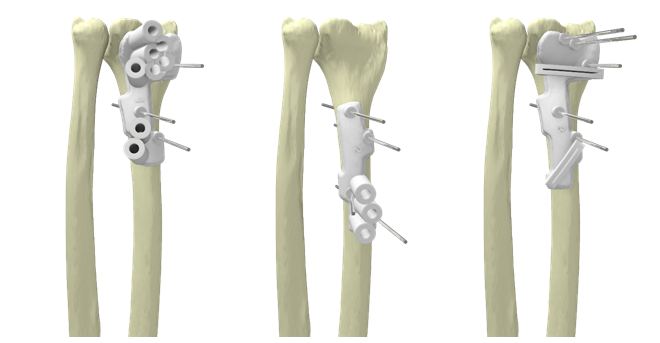

Through Materialis’s solution surgeons can efficiently and accurately plan knee surgeries based on the patient’s unique anatomy and structural damage. Based on that pre-operative plan, patient-specific guides are designed and 3D printed for use during surgery. Lima Corporate will now offer this solution to its surgeons with respect to the unicondylar knee system that it recently acquired from Zimmer.

“Lima is committed to supporting healthcare professionals in their daily efforts to improve the lives of their patients and to enabling better outcomes for patients and healthcare systems,” Luigi Ferrari, CEO of Lima Corporate, stated. “The aim of our collaboration with Materialise is to allow the surgeons we work with to continue to pre-operatively plan and use patient-specific guides in pursuit of more predictable surgical outcomes.”

Lima Corporate provides reconstructive orthopaedic solutions to surgeons who face the challenges of improving the quality of life of their patients. The company, which has access to several in-house Arcam electron beam melting 3D printers, is committed to the development of innovative products and procedures to enable surgeons to select the ideal solution for every individual patient.

Its product range includes large joint revision and primary implants, as well as complete extremities solutions, including fixation. As mentioned, it also included trabecular titanium production capabilities, which are used for skull and hip implants among others. Now, it also adds surgical guides for knee surgery and it really looks like the 3D printed implant portfolio will soon grow to include the entire spectrum of bone implants, quite literally from head to toe.