France’s national railway company, the Société nationale des chemins de fer français (SNCF), has announced the adoption of 3D printing software developer 3YOURMIND’s Agile PLM software.

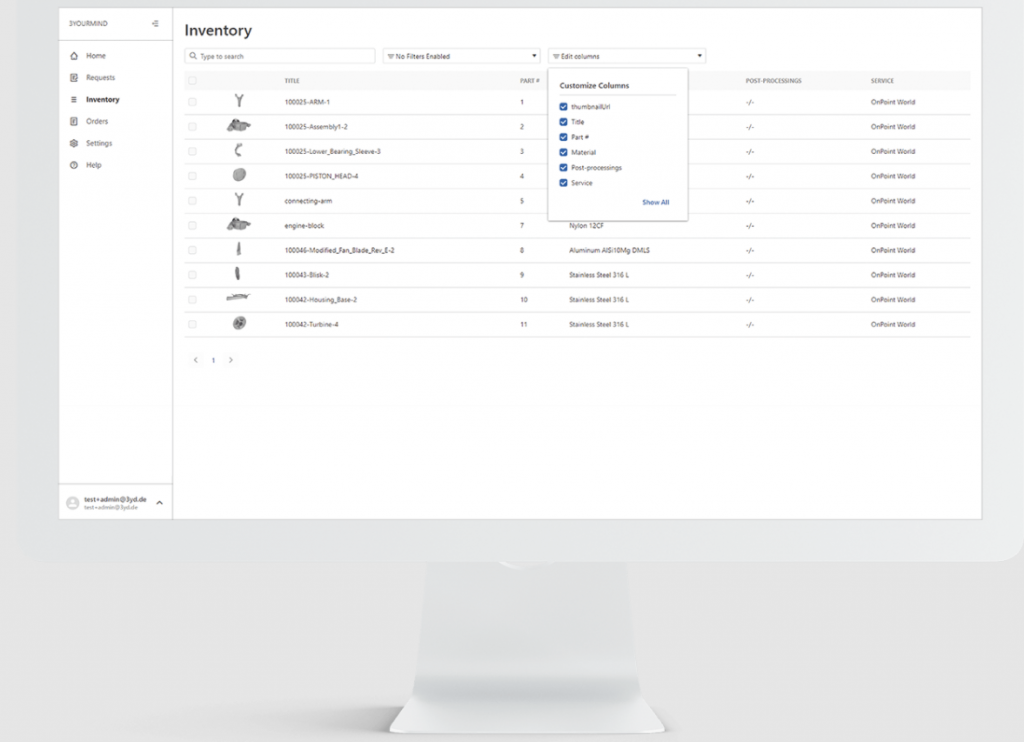

SNCF will use the Digital Qualified Inventory platform to identify, evaluate, and store its additive manufacturing part data in a bid to cut costs and streamline on-demand spare part production. The enterprise software takes into account several parameters of 3D files, including part weight, tolerances, part costs, recurrence of use, and order constraints to better enable customers to manage their digital inventories.

Laetitia Kirschner, an additive manufacturing leader at SNCF, said, “This improved ability for inventory analysis and use case screening will help enhance our cost saving and shorten our lead times dramatically. We are thrilled to partner with 3YOURMIND and reap the full benefits of Additive Manufacturing.”

Maintenance for 14,000 trains

SNCF was founded in 1938, and runs over 14,000 trains over 32,000km of railway every single day. With over 272,000 employees worldwide, the company boasts annual revenues of more than €33.5 billion. As such, it is an essential part of France’s transport infrastructure, and simply cannot afford to have delays in spare part identification or production. When a rolling stock component needs to be replaced, it must be done quickly and cost efficiently.

Unfortunately, due to the complexity of trains, companies like SNCF often have a difficult time with sourcing certain spare parts, especially if the parts in question are particularly old or obsolete. Part data often lacks important technical information, with poor 3D drawings and convoluted ERP data. On top of this, there is the issue of warehousing costs for part storage, making conventional spare part production all the more problematic. This is where 3YOURMIND’s Digital Qualified Inventory comes in.

The Digital Qualified Inventory

SNCF will use the software for regular parts monitoring purposes, and it will enable the company to supply its qualified inventory with parts designed for 3D printing. The platform’s part identifier functionality will also enable SNCF’s engineers to identify and qualify additive manufacturing components based on their materials and processes.

Looking at the results, 3YOURMIND’s software has already been able to identify 10.3% of relevant 3D printing parts in a pool of over 30,000 spare part files. This has helped reduce part delivery times by 85%, from 2.5 months to just 10 days, all while saving the company significant amounts in operational costs. The railway company intends to switch 100 part references from conventional sourcing to 3D printing every year for the next three years.

“We at 3YOURMIND believe that in order to scale up and industrialize Additive Manufacturing, we need to find massive use cases,” added Stephan Kühr, CEO of 3YOURMIND. “Our digital qualified inventory allows SNCF to employ AM in such a use case, and will help revolutionize one of the cornerstone transportation industries in France.”

Spare part production with 3D printing

Beyond just the railway sector, additive manufacturing technology has earned its place as a champion of spare part production. In defense, the Dutch Navy has invested in a set of INTAMSYS 3D printers to improve its on-demand spare part manufacturing capabilities. To house the systems, the Armed Forces have developed what they call the Additive Manufacturing Container for Defense (AMCOD), a mobile repair center in the form of a shipping container.

Elsewhere, in aerospace, Airbus subsidiary Satair recently provided a U.S. airline customer with what it has called the ‘first certified metal printed flying spare part’. The company developed the 3D printed A320ceo wingtip fence after the part became impossible to source from the original supplier, who had difficulties providing the cast version of the component.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.