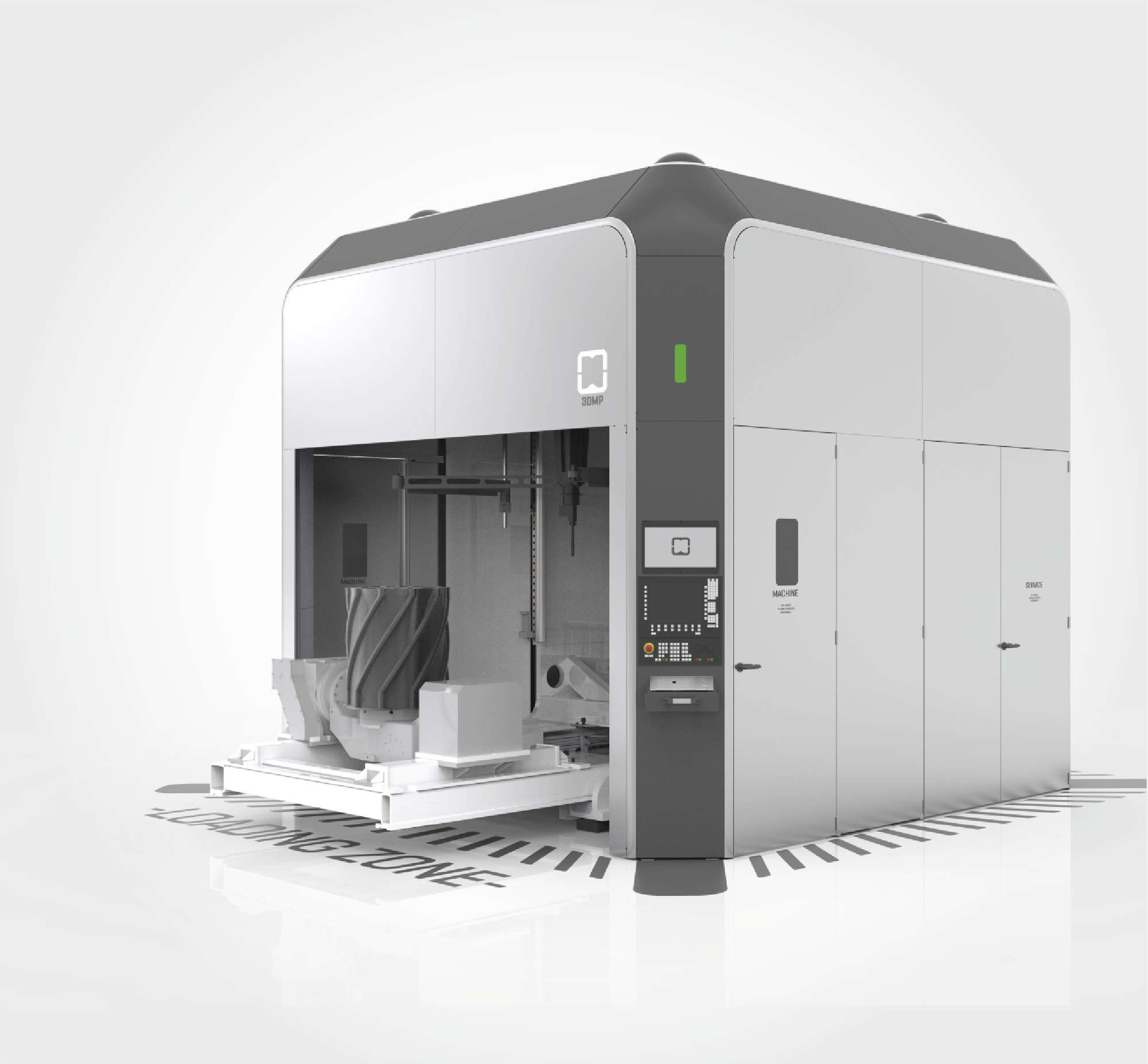

Aircraft Philipp Group, a German supplier of aeronautic metals, has expanded its additive manufacturing capabilities with the purchase of an Arc605 metal 3D printer from GEFERTEC.

As the Berlin-based developer and provider of 3DMP metal 3D printers, GEFERTEC, has established the Arc series of wire-arc melting additive manufacturing systems to create near-net-shape components. This technology is said to eliminate waste with “nearly 100% material utilization.” Rolf Philipp, founder and owner of Aircraft Philipp Übersee explained:

“Developing new aircrafts nowadays requires a radical change in thinking with regards to meeting climate targets and resource-optimized production. Applying this method will lead to radically improved buy-to-fly ratios and will, thus, contribute a great deal to economic and ecological efficiency in the future.”

3DMP technology for aerospace

With locations in Germany, Austria, Israel, and India, Aircraft Philipp Group specialize in the machining, sheet metal forming and additive manufacturing of aluminum, titanium and other alloys used in aeronautics.

The company has over 20 years of experience in processes such as machining, sheet metals, Selective Laser Melting (SLM), Wire Arc Additive Manufacturing, welding, and surface treatments. The integration of the Arc605 and 3DMP technology enables Aircraft Philipp to produce components of up to two tons in mass, thereby responding to user demands for larger parts.

Furthermore, Aircraft Philipp is involved in the joint research project “REGULUS” as part of the fifth aerospace research programme of the German Federal Ministry of Economics and Energy. As a result, the company has accrued experience using powder beds at its Salzburg, Austria facilities.

Last month, GEFERTEC partnered with Linde Group, a Munich-based chemical company, to investigate process gas and oxygen within metal additive manufacturing using 3DMP.

Prior to this, GEFERTEC, delivered an industrial-scale arc403 machine to international aeronautics company Airbus. Tobias Röhrich, CEO of GEFERTEC added:

“We are delighted that Aircraft Philipp Übersee has set its goal towards manufacturing ever greater structural components in the additive fashion. Exactly here lies the special strength and efficiency of 3DMP, which is why it has developed into the new industry standard.”

Nominations for 3D Printing Industry Awards 2019 are still open. Let us know the enterprises, technology, and individuals leading the additive manufacturing sector.

Want the latest 3D printing news? Subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Looking for a fresh start this year? Visit 3D Printing Jobs to commence your career in additive manufacturing.

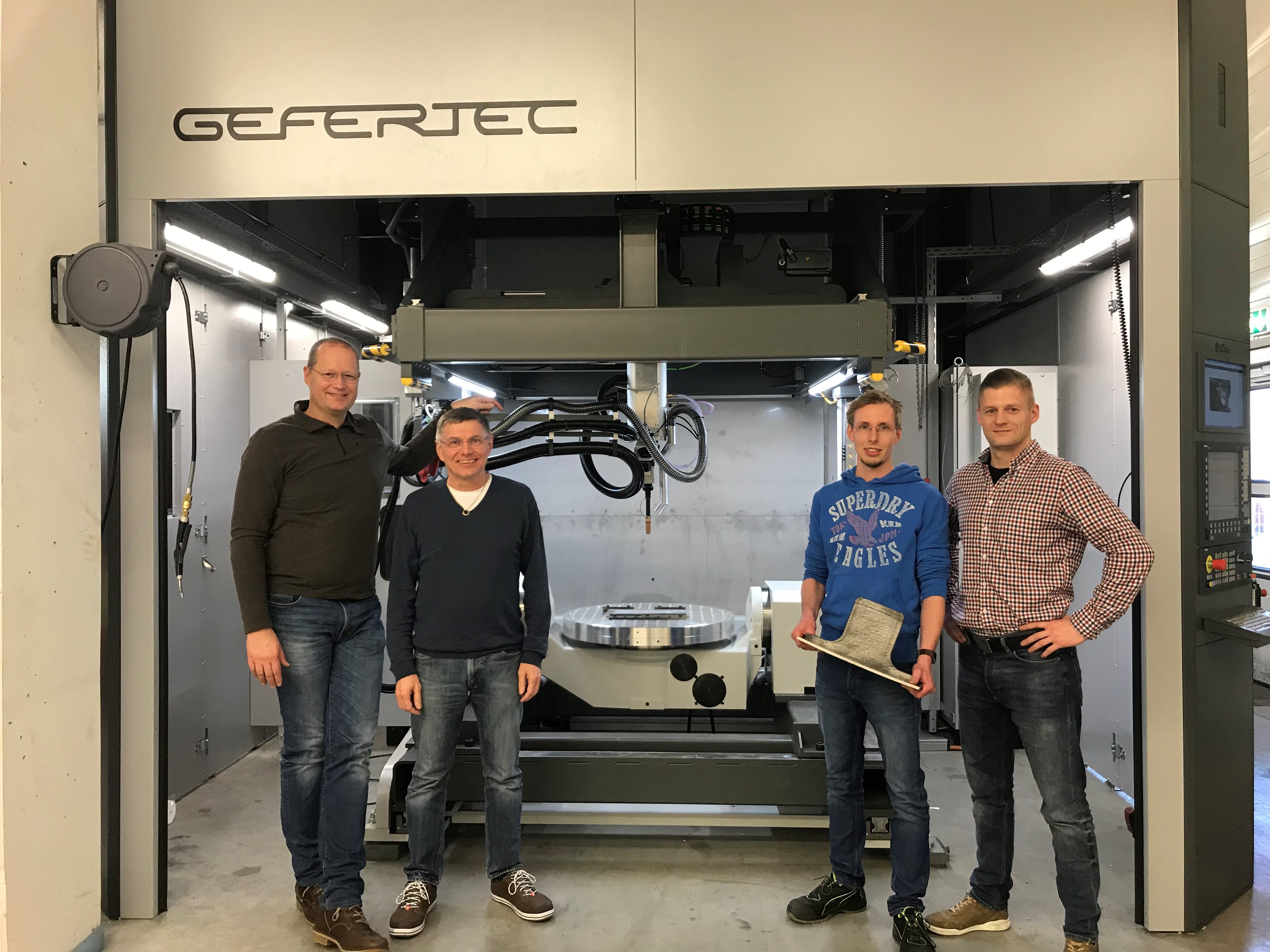

Featured image shows members of Aircraft Philipp Group with an Arc605 3D printer at its facility in Übersee, Germany. Photo via GEFERTEC.