A team of researchers from UCLA has developed a new method of 3D printing entire robots in one go.

The approach relies on specially developed active metamaterials (multi-functional materials) that serve as both the mechanical and electronic systems that make up a robot. These metamaterials can be 3D printed to form tiny ‘meta-bots’ that can crawl, jump, sense their surroundings, and even make decisions on what to do next based on programmed commands.

Since the internal structural, movement, and sensing components are all printed at once, all that’s needed to bring them to life is a small external battery.

“We envision that this design and printing methodology of smart robotic materials will help realize a class of autonomous materials that could replace the current complex assembly process for making a robot,” said Xiaoyu Zheng, principal investigator of the study. “With complex motions, multiple modes of sensing and programmable decision-making abilities all tightly integrated, it’s similar to a biological system with the nerves, bones, and tendons working in tandem to execute controlled motions.”

A new approach to robot building

The conventional robot building process usually involves a series of manufacturing steps to piece together all of the mechanical and electronic components. Since many of these components might be from different suppliers, they’re unlikely to fit together perfectly, resulting in heavier assemblies, unnecessarily large volumes, and non-optimal force outputs. The UCLA 3D printing method is designed to address these issues.

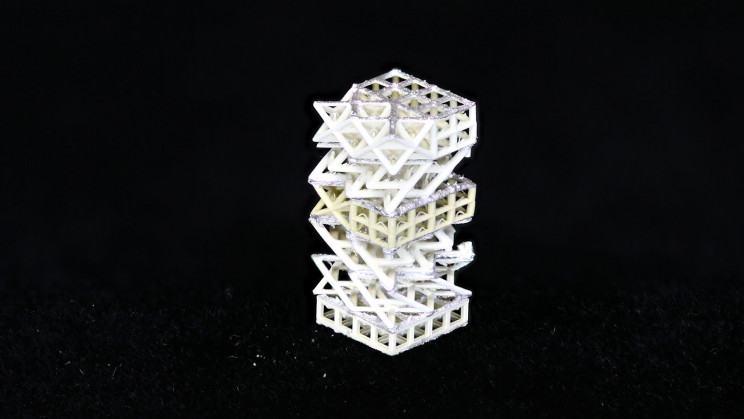

Crucial to the success of the method is the piezoelectric nature of the printed metamaterials. Fabricated in lattice-like shapes, these materials can morph in geometry and move when excited by an electric field, essentially turning electrical energy into kinetic energy.

While the use of piezoelectric materials in robotics isn’t new, their traditional use tends to be limited in travel distance and range of motion. Historically, they also need to be used in conjunction with gearbox-like systems to achieve specific motions.

On the other hand, by 3D printing piezoelectric robots, it’s possible to intelligently design complex structures that bend, rotate, expand, and contract with precision, all without the need for external transmission systems.

“This allows actuating elements to be arranged precisely throughout the robot for fast, complex and extended movements on various types of terrain,” said lead author Huachen Cui. “With the two-way piezoelectric effect, the robotic materials can also self-sense their contortions, detect obstacles via echoes and ultrasound emissions, as well as respond to external stimuli through a feedback control loop that determines how the robots move, how fast they move and toward which target they move.”

Rise of the meta-bots

Cui’s team has already used the 3D printing technique to build three meta-bots. The first can pathfind around S-shaped corners and random obstacles, the second can escape from contact impacts, and the third can walk and jump over rough terrain. They even managed to integrate small onboard batteries and microcontrollers for fully-autonomous operation.

The UCLA researchers envision the method eventually being applied to novel biomedical robot designs, including self-steering endoscopes and swimmer bots capable of delivering drugs to specific areas of the body.

Meta-bots could also be used to explore environments with hazardous conditions such as collapsed build rubble. For example, they could sense their way through confined spaces and find people trapped under debris, or assess threat levels where other diagnostic equipment might not fit.

Further details of the study can be found in the paper titled ‘Design and printing of proprioceptive three-dimensional architected robotic metamaterials’.

The design freedom granted by 3D printing makes the technology an incredibly useful tool for applications like self-propelling robotics. Just recently, researchers from Tianjin University 3D printed a soft robot capable of roaming around on its own. The tube-shaped robot is made of a material called a liquid crystal elastomer, and it self-assembles when in contact with heat. The device leverages cleverly programmed fold patterns to induce strain within its own body, which enables it to roll over like a log.

Elsewhere, researchers from Johannes Kepler University Linz recently 3D printed soft robots with integrated sensor networks capable of stretching to six times their original length. To minimize the environmental impact of the manufacturing process, the team used completely biodegradable materials that could be reprinted multiple times or disposed of hazard-free at the end of their lifetime.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a 3D printed meta-bot capable of moving, sensing, and making decisions all on its own. Photo via UCLA.