U.S. Navy scientists have been issued a 20-year patent for a 3D printable material made of a marine-biodegradable base polymer which would break down over time according to TechLink, the authorized intermediary for the U.S Department of Defense.

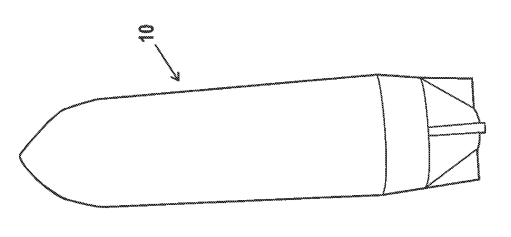

The team of scientists, based at the Naval Surface Warfare Center in Panama City, Florida, believe underwater equipment such as unmanned or autonomous underwater vehicles (UUVs) could be made biodegradable thanks to the new 3D printed material. Inventors of the material, Josh Kogot, Ryan Kincer, and April Hirsch of the center’s Biotechnology Research and Development Lab, received the patent on Tuesday.

“There is an unmet need to produce marine biodegradable 3D printable structures for which the rate of degradation of each structure can be selected for a particular mission,” the patent stated. “It is, therefore, a general-purpose and primary object of the present invention to provide a composition and method for the 3D printing of a marine biodegradable structure for which the rate of degradation can be controlled.”

Understanding UUVs

UUVs are used by the U.S navy to house and deploy oceanic sensors and equipment, used for applications such as mapping, observation, research, and archaeological expeditions.

Some of these UUVs are currently built for single-use only or are designed to function for a set amount of time before they stop working. Retrieval of these objects is often expensive and so many are left abandoned on the ocean floor, which is not a particularly environmentally-friendly disposal solution.

The new 3D printable material could help solve this issue, making UUVs safer to dispose of underwater and counter some of the environmental impacts these vehicles are having on our oceans.

The U.S. Navy is no stranger to investing in 3D printing. In 2018 alone, the U.S. Office of Naval Research (ONR) allocated $2.6 million for the introduction of metal additive manufactured parts; Lockheed Martin entered a $5.8 million contract with the force; and, by the end of the year Naval Air Systems Command (NAVAIR) estimated its fleet relied on the use of 1,000 3D printed parts.

Most recently, the Navy added its latest metal 3D printer, the AML, which is an EOS M290 Direct Metal Laser Sintering (DMLS) system that has been used to make products like portable runway mats and hydraulic components.

The material breakdown

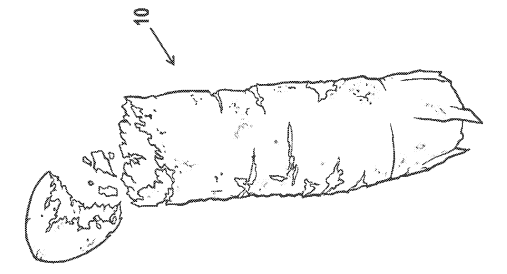

The composition of the 3D printable material is made up of a ratio of a biodegradable base polymer and a gelling agent, which can be preselected to achieve the desired rate of degradation. A combination of polymers such as polycaprolactone (PCL), polyhydroxyalkanoate (PHA), or polybutylene succinate (PBS), can be altered along with an agar gelling agent to enable the material to be 3D printed into any size or shape, and have specified degradation properties.

By increasing the ratio of the agar gelling agent, the composition will provide support for larger amounts of microorganisms and enzyme materials which will accelerate the degradation process of the UUV in question.

The scientists incorporated biological materials, such as synthetic hagfish slime which was invented by the same laboratory in 2018, to facilitate the biodegradation process of the carrier vehicle structure. Microorganisms and enzymes can feed on these biodegradable polymers which make up the structure to aid the process.

According to the patent, 3D printing of the material occurs at relatively lower temperatures, below 120 degrees celsius, to avoid damaging the microorganisms within the biological materials used for the process.

Licensing to businesses

Techlink is providing licensing services of the 3D printable material to businesses at no cost, says Brian Metzger, who works with the Navy technology transfer team in Panama city to help private companies commercialize their inventions.

“Not only can you 3D print this material into just about anything, but to finely control the rate at which it degrades is really useful,” he said. “This technology has the potential to cut costs and benefit the environment, it could have many military and commercial applications for all types of underwater equipment.”

According to Metzger, the new material could be used for a variety of applications, not just UUVs, with the first step to commercializing it being to license the patent.

Nominations for the 2020 3D Printing Industry Awards are still open, let us know who is leading the industry now.

The fourth edition of the 3D Printing Industry Awards Trophy Design Competition is now underway. Enter your design for the chance to win a CraftBot Flow 3D printer.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows The “microSwarm Family of Systems” project led by Naval Surface Warfare Center Panama City Division. Photo via Eddie Green/U.S. Navy.