Global science-based nutrition, health, and sustainable living firm, Royal DSM, has released a new polypropylene material designed for 3D printing a wide range of applications across several industries.

Arnilene AM6002, which has food contact approval in Europe, expands DSM’s powder portfolio for manufacturing and is suitable for Powder Bed Fusion (PBF) 3D printing.

“We are pleased to further extend the material choices for 3D printing with this engineering-grade Arnilene AM6002 powder,” said Geoff Gardner, Innovations Director Additive Manufacturing at DSM.

“This sustainable material is the type of material that manufacturers across many industries are looking for as they move from traditional manufacturing to additive manufacturing, saving production time and cost, as well as maintaining supply chain performance stability year-round.”

DSM’s additive manufacturing portfolio

DSM has an extensive portfolio of 3D printing materials for additive technologies including PBF, Stereolithography (SLA), and Fused Filament Fabrication (FFF).

Earlier this month, the firm launched Arnilene AM6001 GF, a new glass-filled polypropylene material specifically for extrusion-based 3D printing, designed for lightweight and mechanically demanding applications in automotive, infrastructure, water management, and production tooling applications.

Prior to this, DSM acquired part of chemical company Clariant’s additive manufacturing materials business, which saw it take over a defined set of engineering-grade filament and pellet materials. And in March, the company partnered with engineering and consulting firm JuggerBot 3D to explore the potential of fused granulate fabrication (FGF) technology, and subsequent development of pellet 3D printers and materials.

Arnilene AM6002 specifications

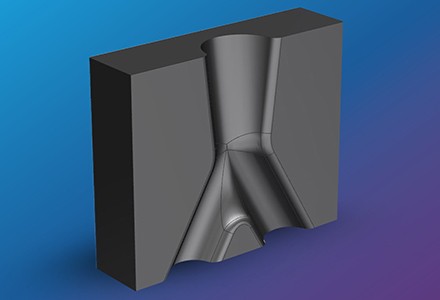

Now available to manufacturers, Arnilene AM6002 offers robust mechanical, chemical, and thermal properties, as well as the ability to print complex designs. The material can be run on existing Selective Laser Sintering (SLS) platforms, is hydrophobic, and can be used to print large batches of engineering-grade parts without compromising ease of post-processing.

Arnilene AM6002 can be post-processed via automated post-processing as well as dyeing, and with a 90% reuse rate, the material produces less waste, making it a more sustainable solution.

Material applications

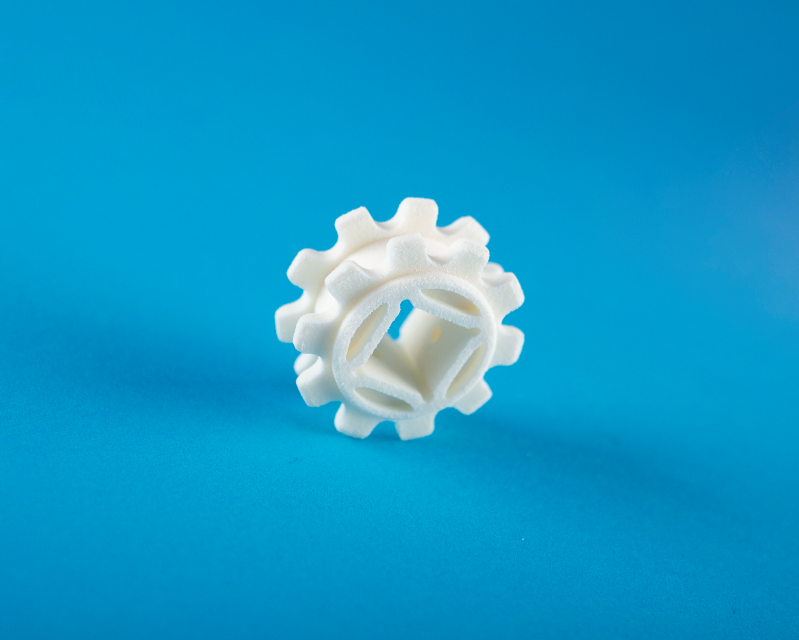

With food contact approval in Europe, Arnilene AM6002 is ideal for applications in the food and beverage or nutrition industries. As such, the material can be used to print parts such as conveyor belt guides, sprockets, slides, dosing blocks, and creepers.

Polypropylene, one of the most commonly used polymers in the world, is also used extensively in the automotive sector. DSM’s Arnilene AM6002 is therefore considerable for applications including dashboard components and interiors, among a range of others in this sector. In addition, the material is suitable for prototyping polypropylene end-use parts.

The 4th annual 3D Printing Industry Awards are coming up in November 2020 and we need a trophy. To be in with a chance of winning a brand new Craftbot Flow IDEX XL 3D printer, enter the MyMiniFactory trophy design competition here. We’re happy to accept submissions until the 30th of September 2020.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows SLS 3D printed conveyer belt sprocket using DSM’s new Arnilene AM6002. Image via DSM.