Nutritional science and materials specialist Royal DSM has announced a new glass-filled polypropylene (PP) material specifically for extrusion-based 3D printing. The pellet composite, Arnilene AM6001 GF, is designed for lightweight and mechanically demanding applications in automotive, infrastructure, water management, and even production tooling.

Geoff Gardner, Innovations director Additive Manufacturing at DSM, states: “Developed by our experts, Arnilene AM6001 GF offers industrial customers an industry-standard material with robust mechanical, thermal and chemical performance in an additive manufacturing format. By using a material they already have experience with, they can fully focus on 3D printing and its benefits for their business.”

Glass-filled polypropylene for 3D printing

PP is one of the most commonly used polymers in the world. It is heralded for its chemical and fatigue resistance, elasticity, toughness, and high electrical resistivity. As a result, the thermoplastic is typically used for chemical containers, heavy-use hinges, and electronic components. With the addition of glass fiber as a strengthener, DSM claims to have preserved the base material’s desirable mechanical, thermal, and chemical properties – all while optimizing the pellets for the 3D printing process.

Gardner adds: “Availability of engineering-grade materials with the right property set is the next step in the additive manufacturing revolution.”

During development, DSM’s materials scientists worked closely with equipment partners to ensure the composite could be printed with both open and closed format 3D printers. The pellets reportedly have a low carbon footprint, as a result of reduced energy consumption and low Life Cycle Assessment, making them a sustainable alternative to similar 3D printing materials.

DSM’s additive manufacturing materials

The firm already has an extensive portfolio of 3D printing materials for a variety of additive technologies including SLA, PBF, and FFF. Earlier this year, DSM acquired a portion of chemical company Clariant’s additive manufacturing materials business, further extending its offering. The agreement saw DSM taking over a defined set of engineering-grade filament and pellet materials, including some flame retardant and additive-reinforced composites.

DSM also recently partnered with engineering and consulting firm JuggerBot 3D to further develop fused granulate fabrication, or pellet extrusion, 3D printing technology. The partners are currently in the process of developing new pellet 3D printers and compatible materials, primarily for industrial production applications.

The 4th annual 3D Printing Industry Awards are coming up in November 2020 and we need a trophy. To be in with a chance of winning a brand new Craftbot Flow IDEX XL 3D printer, enter the MyMiniFactory trophy design competition here. We’re happy to accept submissions until the 30th of September 2020.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

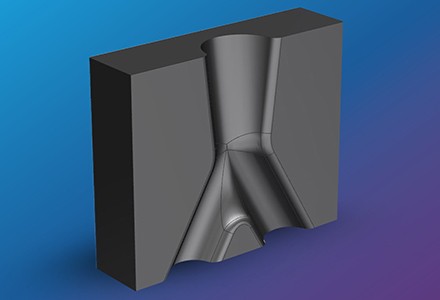

Featured image shows sewage manhole design – a possible application of DSM’s new Arnilene AM6001 GF pellets. Image via DSM.