A team from the Fraunhofer Institute for Ceramic Technologies and Systems (IKTS) has developed a Multi Material Jetting (MMJ) system to combine multiple materials into a single additively manufactured part.

Based on thermoplastic binder systems, the new system utilizes high-performance materials such as ceramics and metal, combining different materials and their various properties into a single product.

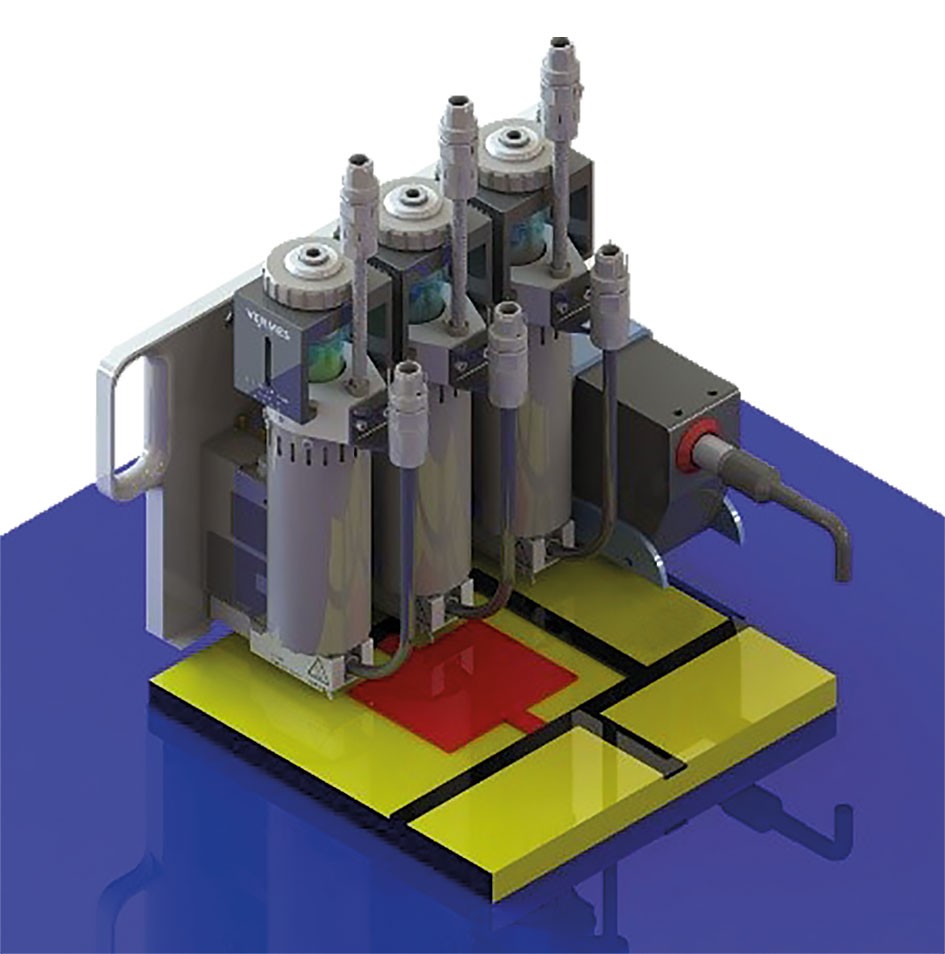

“Right now, we can process up to four different materials at a time,” said Uwe Scheithauer, a researcher at Fraunhofer IKTS. This technology could enable companies to produce highly integrated multi-functional components with individual properties.

Additive manufacturing ceramics

The early years of additive manufacturing were dominated by polymers, but this has since expanded to include metals and ceramic-based materials. One company at the forefront of this is binder jetting 3D printer manufacturer, ExOne, whose 3D printers are capable of printing metals, ceramics, and composites, with new materials being qualified continuously.

Most recently, ExOne bestowed ‘Third Party Qualification’ status on its Iconel 718 nickel-based superalloy, typically used in high-stress aerospace, energy, and automotive applications, similar to the applications the Fraunhofer researchers believe their MMJ system would be suitable for. Iconel is characterized by its high strength, hardness, corrosion and chemical resistance, and excellent welding properties, as well as its ability to withstand extreme temperatures ranging from sub-zero to 700°C.

Across other sectors, 3D printing specialist Lithoz’s proprietary Lithography-based Ceramic Manufacturing (LCM) technique was recently used to 3D print Corning glass ceramic materials for the first time, while ceramics expert 3DCERAM-SINTO has advanced its ceramics 3D printing technology to develop the next generation of medical X-ray imaging systems.

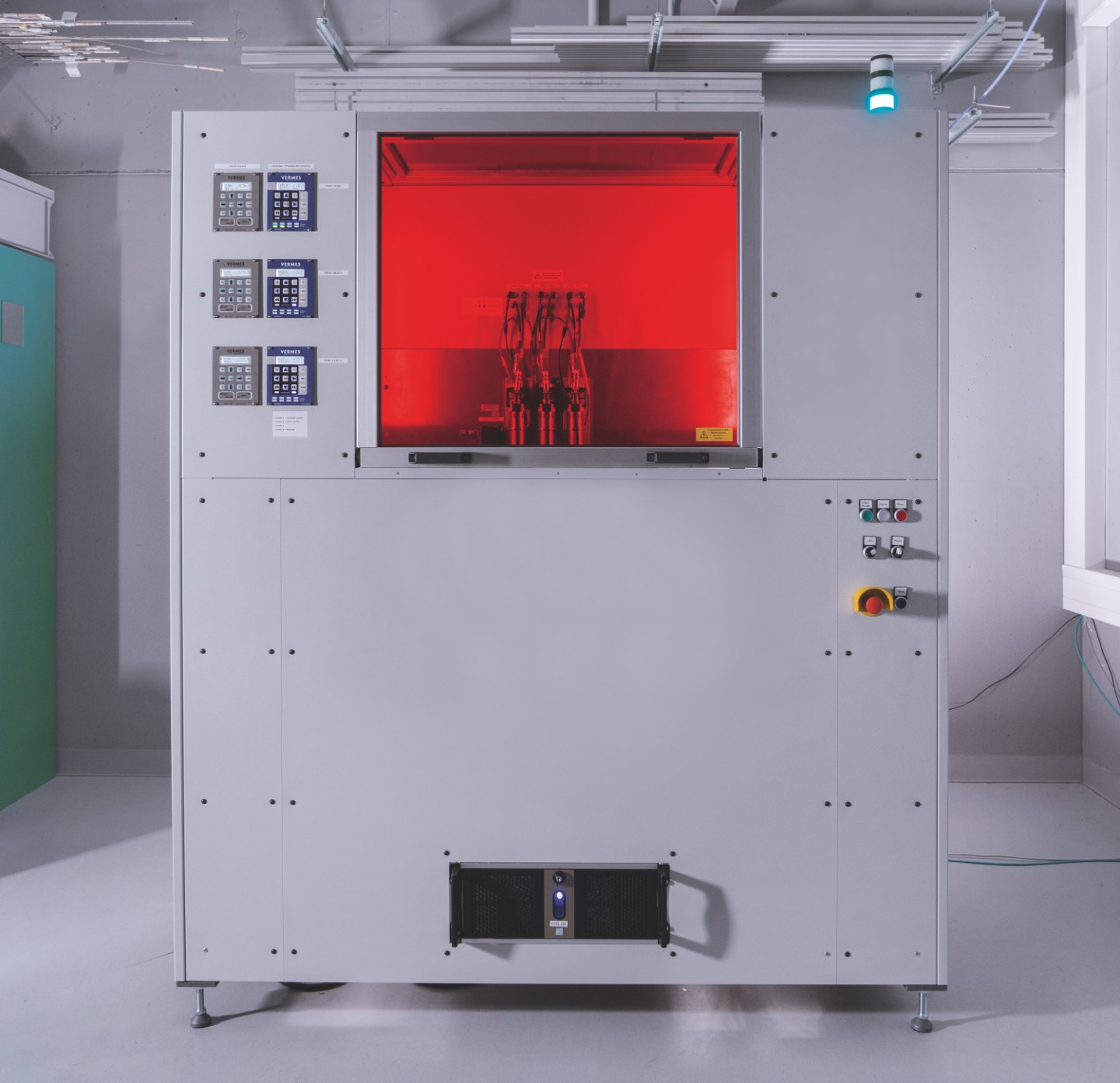

Fraunhofer IKTS’ new system

Fraunhofer’s MMJ system fabricates parts in a continuous process. Ceramic or metal powder from which the part will be made is uniformly distributed in a thermoplastic binder substance. The slurries produced from this are then loaded into micro-dosing systems (MDS) in order to commence the manufacturing process. The slurries are melted in the MDS at a temperature of around 100 degrees Celsius to create a substance that can be released in tiny droplets.

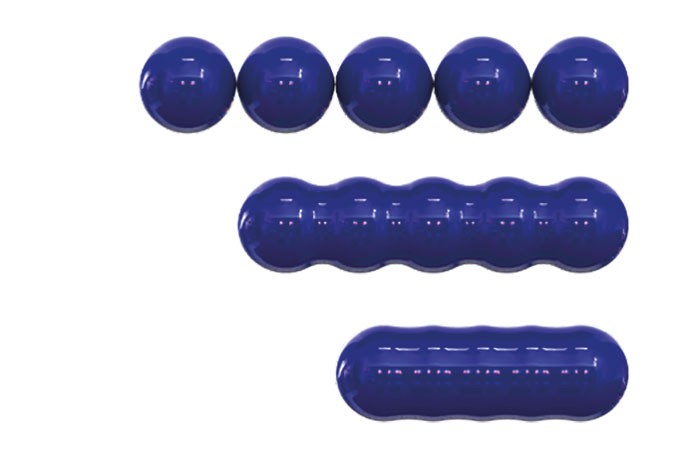

A corresponding software program developed by the researchers ensures the precise positioning of the droplets, which are deposited one by one via a high-precision, computer-controlled process. Gradually, the part is built up at rates of up to 60mm and 1,000 drops a second.

The system works with droplet sizes of between 300 and 1000 μm, creating deposited layers with heights of between 100 and 200 μm. The maximum size of parts that can currently be manufactured is 20 × 20 × 18 centimeters.

“The critical factor here is the custom dosing of the metal or ceramic slurries,” explained Scheithauer. “Getting the dosing right is key to ensuring that the additively manufactured final product takes on the required properties and functions during subsequent sintering in the furnace, including properties such as strength, thermal conductivity, and electrical conductivity.”

Potential applications

One example where Fraunhofer researchers have applied the IKTS system is in the making of highly complex parts such as the ignition system in a satellite propulsion engine made of ceramics. The ability of ceramics to withstand heat makes them a suitable material option for satellite combustion chambers, which reach extremely high temperatures.

The ignition system combines both electrically conductive and insulating areas within a single component and requires three dosing systems: one for a support material that disintegrates during heat treatment in the furnace, a second for the electrically conductive component, and a third for the electrically insulating component.

According to the researchers, MMJ could also have several applications in the consumer products market, and is also suitable for more than just manufacturing multi-functional components due to its high precision and flexibility.

“We could also use it to make blanks for carbide parts, for example,” said Scheithauer. “Thanks to the tremendous precision of the dosing systems, the contours of the blanks would already be very close to those of the end product. They would therefore require very little subsequent grinding as compared to conventional methods. That’s a big advantage when you are working with carbide.”

Now that Fraunhofer IKTS’ project has demonstrated the technology works in practice and is scalable, it’s next step is to validate the technology for commercial use. In addition to supplying the hardware, Fraunhofer IKTS says it can also help industry customers to develop the materials and software required for process monitoring and automation, meaning they can get all they need from a single source.

Those interested in the technology can sign up for the online AM Ceramics meets CERAMITEC conference, taking place September 16-17.

The 4th annual 3D Printing Industry Awards are coming up in November 2020 and we need a trophy. To be in with a chance of winning a brand new Craftbot Flow IDEX XL 3D printer, enter the MyMiniFactory trophy design competition here. We’re happy to accept submissions until the 30th of September 2020.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Fraunhofer IKTS’ system for Multi Material Jetting of high-performance components with combined properties or functions. Image via Fraunhofer IKTS.