Two innovative students, Kate Reed (of NuVu Studio) and Nathaniel Tong (of RIT), joined together to create the Hand Drive after being challenged to “hack” and improve the structure of the wheelchair. What research led them to discover was that the best physical motion for propelling the chair was achieved with a level-powered approach, one that generally costs $2,000 – $10,000 dollars just to utilize. That is until Reed and Tong sought to solve this expensive problem with 3D printing by designing and creating a lever-powered attachment for the wheelchair.

This attachment, which only costs $40 to produce, allows any wheelchair to power itself with a lever-powered rowing motion, a method of motion that is proven to be much better for your back. This is a major price difference, 1% of the cost in fact, which is especially beneficial for the often underserved disabled community. Not only is the designed attachment affordable, Reed and Tong have also made the Hand Drive an open source project, allowing anyone with access to a 3D printer to both acquire and modify it.

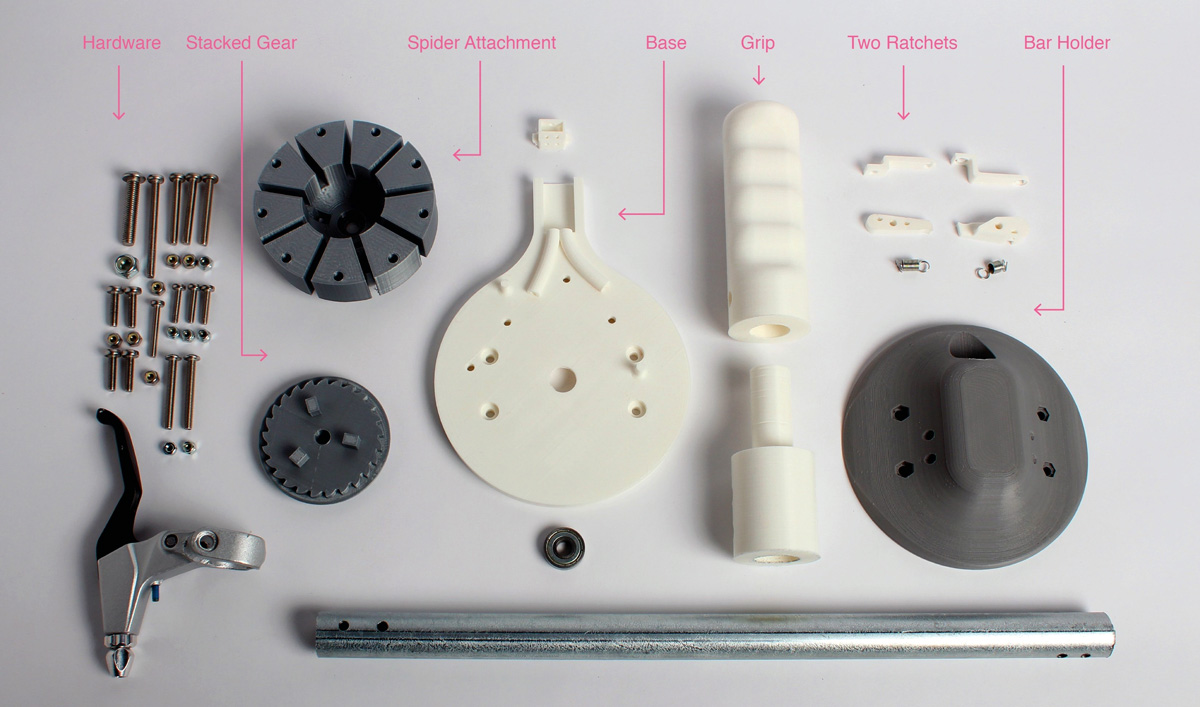

Reed and Tong have developed five major prototypes thus far, and, even though they have achieved high levels of functionality, they are still working endlessly to improve their design. They began the design by experimenting with a dual ratchet mechanism, which works to spring the wheelchair forward or backwards depending on which ratchet the user engages with. After adding three double-sided ratchets onto one of their prototypes, looking to improve the function and speed provided by the Hand Drive, Reed and Tong decided to implement a planetary gear system. The gears are milled and set with the 3D printed planetary ratchets into one functional unit, making the wheelchair propel forward when the clutch is pulled (which winds back the set of gears and ratchets, causing quick forward movement). Though the gears themselves are not yet 3D printed, Reed and Tong are working out the kinks. “In the big picture, one of our goals is to work towards a design where the planetary ratchets can be 3D printed instead of milled,” they write in their project log, “We never want to lose sight of our goal to make the Hand Drive affordable and accessible for all.”

The project, which has been selected by the Maker-friendly Hackaday.io platform as a one of ten finalists for their 2015 Best Product Finalists, is still being improved by the day. Regardless of how far they get with there design, these two students have created an opportunity for wheelchair users to access an affordable, open source modification to improve their mobility and overall well being. What was once unaffordable for those with disabilities can now be printed in their very own home for an unprecedented fraction of the cost. I can’t help but wonder what innovative modification Reed and Tong will develop as their design progresses!