Researchers from TU Wien have fabricated artificial human “tissue on a chip” using a multi-photon lithography technique which could eliminate the need for animal testing in the future.

The laser-based method enables the researchers to guide individual cells to specific locations within a hydrogel to form reproducible specialized tissue systems. These tissues can then be examined under precisely controlled conditions on a chip, holding promise for pharmaceutical research such as testing the efficacy of new drugs.

AM as an alternative to animal testing

In recent years, advances in bioprinting and tissue engineering technologies have offered increasingly viable alternatives to the use of animal models in experimental medical research. While viable patient-specific tissues for trialing the efficacy of drugs remain largely experimental for now, there is significant progress being made towards this goal.

For instance, bioprinter manufacturer CELLINK has pledged to advance its research into animal cruelty-free cellular testing models, while the University of Stuttgart is working on the development of microscale bioprinted skin models to trial the efficacy of cancer drugs.

Elsewhere, Fluicell’s Biopixlar platform is producing highly-complex neural models which could offer future applications for clinical drug screening, while UpNano’s NanoOne Bio system is hoping to reduce the number of animal testing experiments with its 3D printed cell-culturing microstructures.

Most recently, the Institute of Bioengineering of Catalonia (IBEC) announced it was coordinating the EU-funded BRIGHTER project with the goal of developing new 3D bioprinting processes in order to reduce animal testing within the fields of tissue engineering and regenerative medicine.

Fabricating human “tissue on a chip”

Creating tissue structures in a lab often begins with living cells embedded in a hydrogel, usually a biocompatible material with properties very similar to those of biological tissue. Cells can migrate through the hydrogel and form a tissue, however the ability to precisely control this process and direct the cells towards a predetermined blueprint has so far been challenging.

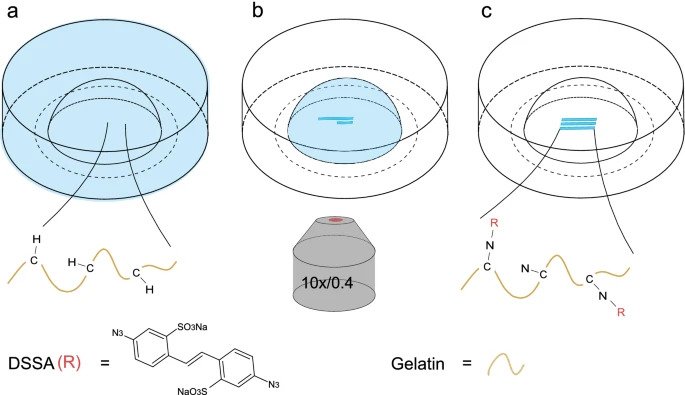

By means of a laser, multi-photon lithography techniques can create intricate 3D microstructures with feature sizes as small as 100nm within photosensitive materials. The method has proven to be a suitable tool to precisely control the microenvironment of cells by altering the biochemical and biophysical properties of the hydrogel matrix they are encapsulated within.

According to Professor Aleksandr Ovsianikov, Head of the 3D Printing and Biofrabrication research group at TU Wien, the success of the team’s technique is due to the addition of “special molecules” that change the physical properties of the hydrogel when activated by a laser.

At the precise point of contact with the laser, the hydrogel becomes softer and more permeable, enabling the creation of predetermined paths throughout the hydrogel along which cells can migrate.

“The molecule couples to the network of the hydrogel, at this point the network becomes more hydrophilic,” explained TU Wien’s Simon Sayer. “This changes the physical properties, and in this way it is possible to create a 3D pattern through which the cells can pass more easily than elsewhere.”

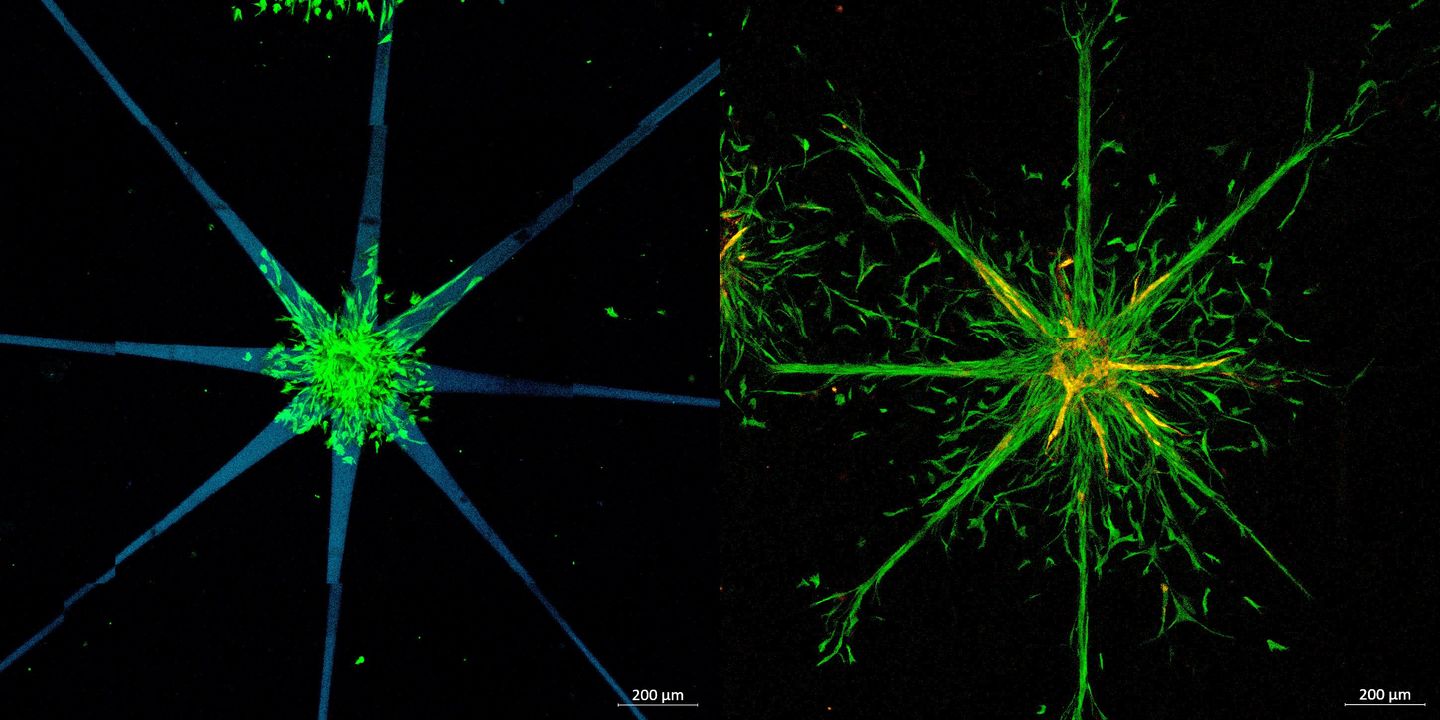

As a result, the researchers were able to produce star-shaped or lattice-shaped cell structures within the hydrogel that mimic biological functions such as blood vessels. These tissues structures can then be placed on a chip of a few centimeters in size and be precisely supplied with specific nutrients or pharmaceutical compounds. How the tissues interact with each other can then be observed, allowing the team to gather important information about the effect of different drugs without the need for animal testing.

“But this only works if we can precisely control the properties of these tissues,” said Tommaso Zandrini, also of TU Wien. “Firstly, these experiments need to be reproducible, so if you want several tissue samples with exactly the same microstructure, and secondly, you also need to be able to precisely connect the different samples – for example, if you’re studying the interaction between a small piece of heart muscle tissue and a small piece of liver tissue.”

By leveraging their multi-photon lithography technique, the TU Wien team is able to accurately understand the interaction between different tissues as structures such as blood vessels can be printed in exactly the right place, while enabling the complexity of customized tissue samples to be significantly increased.

Further information on the study can be found in the paper titled: “Guiding cell migration in 3D with high-resolution photografting,” published in the Scientific Reports journal. The study is co-authored by S. Sayer, T. Zandrini, M. Markovic, J. Van Hoorick, S. Van Vlierberghe, S. Baudis, W. Holnthoner, and A. Ovsianikov.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews, and webinar replays.

Featured image shows leveraging their multi-photon lithography process, the researchers created star shaped patterns (left), into which the cells can grow (right). Image via TU Wien.