Just a week after announcing a new versatile, performance 3D printing material, taulman3D has already launched another new filament. The material maker has returned to its routes as one of the first providers of Nylon for desktop fabricators with a new and improved Nylon 680 filament.

Developed in conjunction with Graphene 3D Lab, which announced one of the first graphene composite 3D printing filaments not too long ago, Nylon 680 is more than a year in the making. The material is specifically engineered to avoid clumping problems typical of 3D printing with nylon, which can cause gaps and bonding issues when making objects. Moreover, Nylon 680 is designed to be dishwasher safe, so that it can survive boiling water and steam.

For manufacturing or conversion from pellets to 3D Printing “line”, another feature of Nylon 680 is that it is not extruded, but “drawn” and done so, under water. The water in the draw process is maintained and continually refreshed to have a pH of ~7.0 – 7.2 and an ORP greater than 600mv. From the draw process, the material is down spooled by machine and delivered to the taulman3D facility where each spool is checked, labeled and vacuum sealed. Spools are labeled on both sides and contain 2 QR codes. One code for printing information and the other denotes the manufacturing batch code/date of mfg.

Nylon 680 is FDA Food and Beverage compliant, which may be the first Nylon filaments to have such a classification. Whether or not the extruder on a given 3D printer is food safe, however, is probably a different matter and the porosity of prints made on desktop printers may also allow germs to hide in these microscopic pores. I reached out to Tom, of taulman3D, to get his thoughts. He tells me that, for now, it might be a good idea to seal prints to ensure that microbes can’t hide.

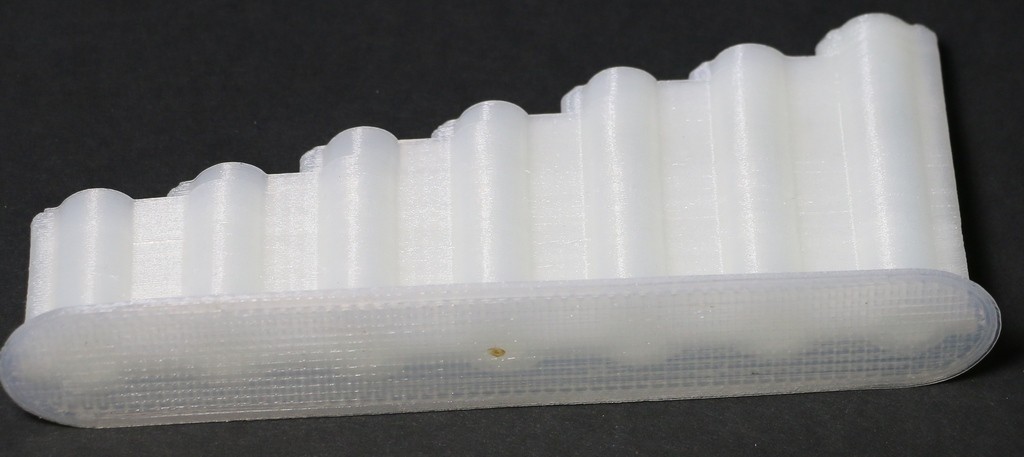

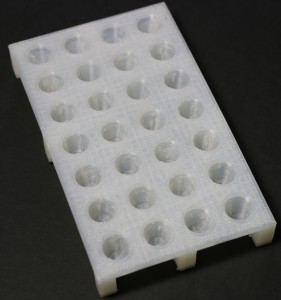

One other feature worth noting of this material is that its clarity allows for the relative ease of non-destructive evaluation of parts printed in Nylon 680 using a light table. Due to its clarity, users can see if a part has good adhesion on the inside of a part, where the infill meets the perimeter. The full specs of the material, as stated by the manufacturer, are listed below:

- Tensile Strength = 4,686PSI +

- Modulus PSI =28,634

- Max Elongation at break = 226%

- Print Temperature = 250C – 255C

- Nozzle size = Any

- Print Bed =

Cold = BuildTak with coat of PVA

Hot = Glass heated to 50C with coat of PVA

(PVA is 20% water and 80% “Elmers Glue All – or equivalent”) - Shrinkage = 0.006 in/in

- Transmission = ~70%

- Color = Subtle translucent Shell White when printed solid – May be dyed with acid based dyes.

- Availability = 1.75mm and 2.85mm Material is on-hand and shipping worldwide now.

If you want to start 3D printing with this Nylon material, you can head over to taulman3D. This is only the beginning of taulman’s partnership with Graphene 3D Labs, which, according to taulman, will help them test the filament even further. And, by teaming up with such an edifice of the 3D printing community as taulman3D, Graphene 3D Labs gains extra validation for its own line of products. That sort of validation may be necessary when there are a number of other, less trustworthy companies exploring the use of graphene in 3D printing. A win-win for all!