Researchers from the Singapore University of Technology and Design (SUTD) and Southern University of Science and Technology (SUSTech) in Shenzhen, China, have proposed a method of fabricating microlens arrays using oscillation-assisted digital light processing (DLP) 3D printing.

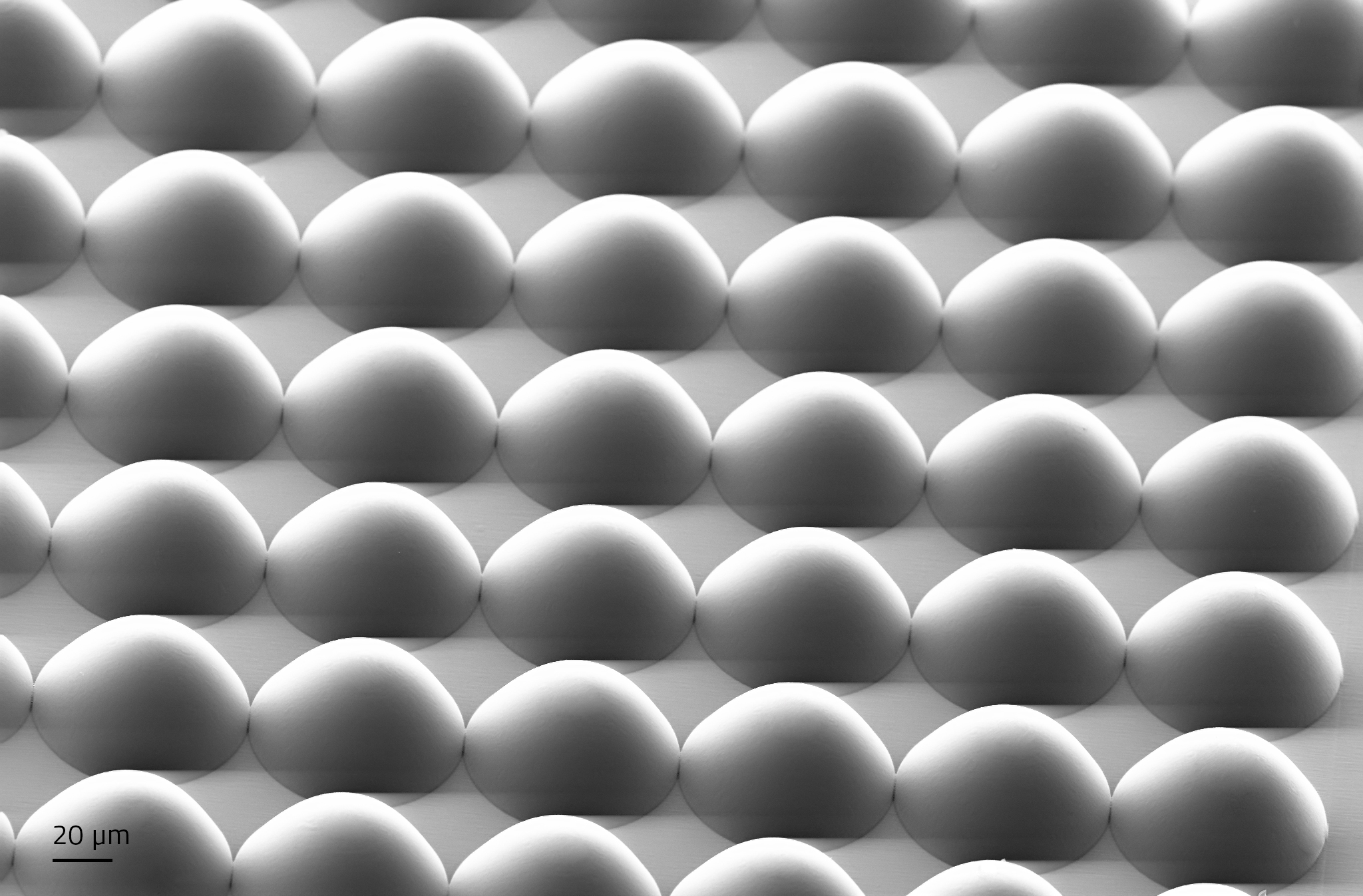

A microlens array consists of multiple micron-sized lenses with optical surface smoothness. Typically, most 3D printing methods have been unsuccessful in fabricating optical components due to the presence of coarse surface roughness in 3D printed objects. However, using projection lens oscillation, the research team has developed an approach for producing microlens arrays with optical surface smoothness using DLP 3D printing.

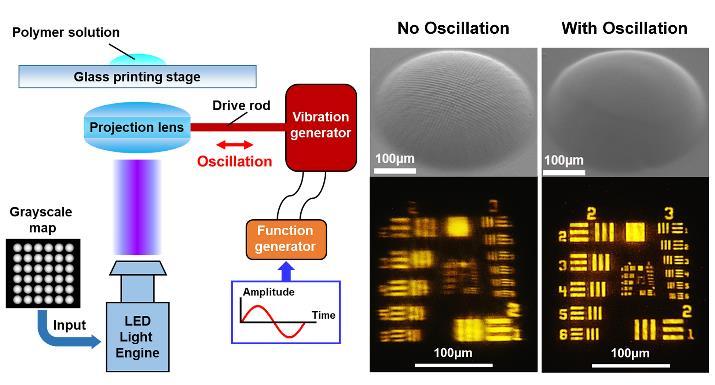

Explaining the process, project leader and Associate Professor Qi Ge from SUSTech stated “In our approach, the computationally designed grayscale patterns are employed to realize microlens profiles upon one single UV exposure which removes the staircase effect existing in the traditional layer-by-layer 3D printing method, and the projection lens oscillation is applied to further eliminate the jagged surface formed due to the gaps between discrete pixels.”

Altering DLP 3D printing with mechanical oscillation

A microlens is a small lens, often measuring as small as 10 micrometres. Microlens arrays contain multiple lenses formed in a one-dimensional or two-dimensional array on a supporting substrate. They have attracted significant attention due to the increasing demand for miniaturization of optoelectronics, which are electronic devices and systems that source, detect and control light. Microlens arrays have therefore become an important micro-optics device used in various compact imaging, sensing, and optical communication applications.

Producing microlens arrays has proven difficult, according to the researchers, as limitations such as high time consumption, high process complexity, lack of fabrication flexibility, and difficulty in consistency control still exist for many manufacturing techniques.

DLP 3D printing is a process that uses a digital projector to cure photopolymer resin and produce 3D printed parts. It is often used for highly detailed 3D printing, and is considered a faster method than SLA, a similar 3D printing process. Although DLP 3D printing offers great flexibility in the fabrication of microlens arrays with different sizes, geometries and profiles, it has been unable to produce parts with optically smooth surfaces.

To overcome this, the SUTD and SUSTech researchers suggested integrating DLP 3D printing with mechanical oscillation and grayscale UV exposure. Oscillation helps to remove the jagged surface formed by discrete pixels in a 3D printed part, whereas the grayscale UV exposure removes the staircase effect common to 3D printing, where layer marks are visible. The result would be an ultrafast and flexible fabrication method for microlens arrays with optical surface smoothness.

To prove the viability and effectiveness of the approach, the research team has conducted detailed morphology characterizations, including scanning electron microscopy (SEM) and atomic force microscopy (AFM). Results suggested that the integration of projection lens oscillation with DLP 3D printing reduces surface roughness from 200 nm to about 1 nm. Professor Ge added:

“Relative to the other fabrication method, our oscillation assisted DLP based printing method is energy- and time-efficient without degradation of optical performance, which is convenient for commercialization and deployment into mass production. Also, this approach provides instructive inspirations for other manufacturing fields with high demands for ultra-smooth surfaces.”

3D printing microlenses

Although the research team has specifically adapted DLP for producing microlens arrays, various other 3D printing technologies are already suited towards its production. For example, Germany-based Nanoscribe manufactures two-photon additive manufacturing systems that are capable of producing microlens arrays. This year it launched a 3D printer called Quantum X, which uses two-photon lithography for fabricating nano-sized refractive and diffractive micro-optics which can be as small as 200 microns.

At the end of 2018, the company also introduced the Photonic Professional GT2 3D printer for microfabrication and maskless lithography, also capable of producing microlenses.

SUTD and SUSTech’s study, “Ultrafast Three-Dimensional Printing of Optically Smooth Microlens Arrays by Oscillation-Assisted Digital Light Processing, is published in ACS Applied Materials & Interfaces“. It is written by Chao Yuan, Kavin Kowsari, Sahil Panjwani, Zaichun Chen, Dong Wang, Biao Zhang, Colin Ju-Xiang Ng, Pablo Valdivia y Alvarado, Qi Ge.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows optically smooth microlens array is fabricated by an oscillation assisted 3D printing method. Image via SUTD.

Featured image shows a microlens array 3D printed on a Quantum X machine. Image via Nanoscribe.