Award-winning 3D printer OEM GE Additive has entered into a five-year cooperative research and development agreement (CRADA) with the US Department of Energy’s Oak Ridge National Laboratory (ORNL). Both parties have agreed to focus their research on processes, materials and software in order to drive industrialization and support broader adoption of additive manufacturing technology.

“We’re really looking forward to applying the collective brainpower and expertise from both organizations to address the challenges around industrialization, but we also have an eye on the future,” commented Josh Mook, innovation leader, GE Additive.

“The next wave of additive technology is already upon us – whether that’s binder jet or rapid advances in software – so, we’re excited to see where the next five years will take us”

ORNL and GE partnership

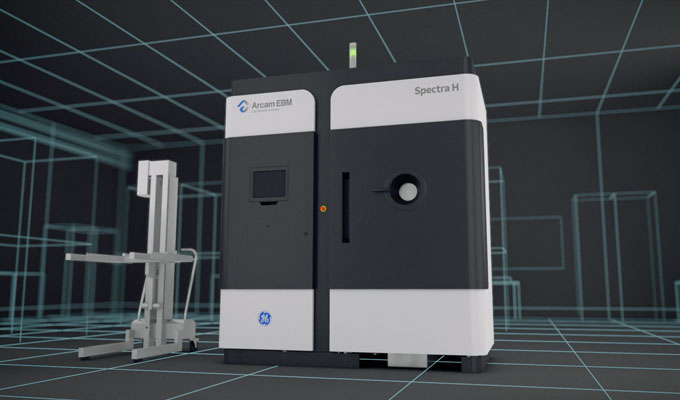

ORNL is sponsored by the DOE, and conducts scientific programs that focus on materials, neutron science, energy, high-performance computing, systems biology and national security. Previously, ORNL had entered into a CRADA with 3D printer manufacturer Arcam EBM in 2012, a company that has since been acquired by GE.

ORNL purchased its first Arcam EBM system in 2009 for the US Department of Energy’s Manufacturing Demonstration Facility in Knoxville, Tennessee. Working with the Arcam EBM teams, ORNL has focused on establishing avenues for companies in multiple US manufacturing sectors to adopt EBM technology.

ORNL’s CRADA with Arcam EBM in 2012 was focused on improving the process reliability of EBM technology, expanding the technology to new materials systems, and validating the properties of Titanium Ti-6Al-4V materials.

The new CRADA with GE Additive now supersedes the older agreement between ORNL and Arcam EBM. It covers all GE Additive equipment, materials and engineering services, with a focus on developing novel additive technologies and utilizing them for creating commercial products. Specifically, the two companies will research process simulation methodologies and in-situ monitoring and quality control for both EBM and DMLM systems, materials modeling and development, and the commercialization of equipment and processes.

“We’re excited to again push the boundaries with GE and lower the barriers for widespread adoption of more efficient, low-cost manufacturing techniques,” added Moe Khaleel, associate laboratory director for Energy and Environmental Sciences at ORNL.

Developing additive manufacturing at ORNL

The development of its collaboration with GE is the latest in a series of updates surrounding ORNL and its efforts in advancing additive manufacturing technology.

In May 2019, ORNL announced an agreement with Ohio-based manufacturer of welding products Lincoln Electric to advance the development of large-scale metal additive manufacturing technology.

Leading industrial 3D printer provider ExOne also revealed that it was working with ORNL to advance binder jet technology for sand and metal 3D printers. The two organizations have been working on developing binder jet technology since 2015.

Recently, the DOE-funded laboratory also signed a memorandum of understanding with the University of Toledo (UToledo) in Ohio to conduct research into advanced materials for the automotive sector.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Members of GE, ORNL and DOE at the signing ceremony in GE Additive’s Technology Center in Cincinnati. Photo via ORNL.