Scientists from the School of Medicine, Shenzhen University, China, have developed a Freeform Reconfigurable Embedded All-Liquid (FREAL) bioprinting method to create 3D architectures microstructures. Through compartmentalized bioink with living cells, the 3D printed tissue constructs can facilitate medical models, organ-on-chips, thus furthering regenerative medicine research.

“This offers unique opportunities and powerful tools since limitless formulations can be designed from among a breadth of natural and synthetic hydrophilic polymers to mimic tissues,” states a paper published in Advanced Materials.

“This printing approach may be useful to engineer biomimetic, dynamic tissue-like constructs for potential applications in drug screening, in vitro tissue models, and regenerative medicine.”

Freeform reconfigurable embedded all-liquid bioprinting

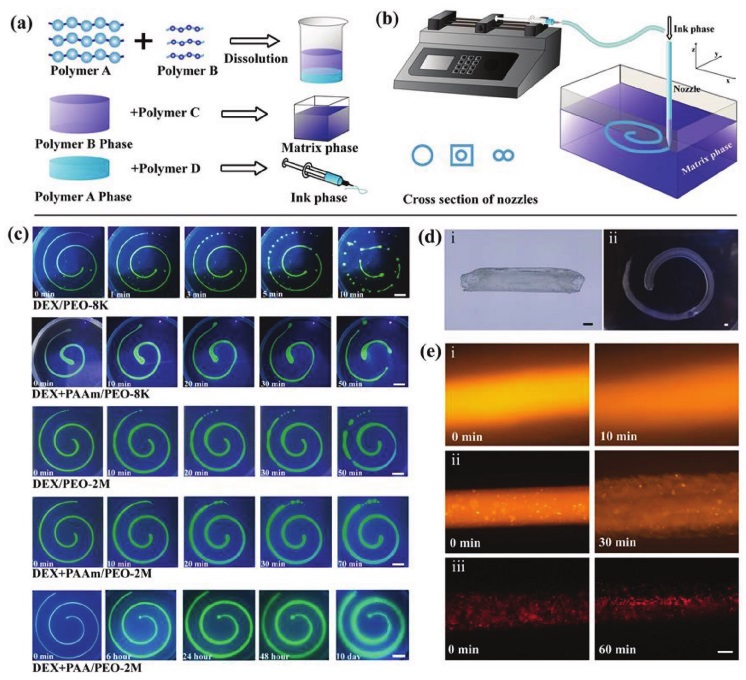

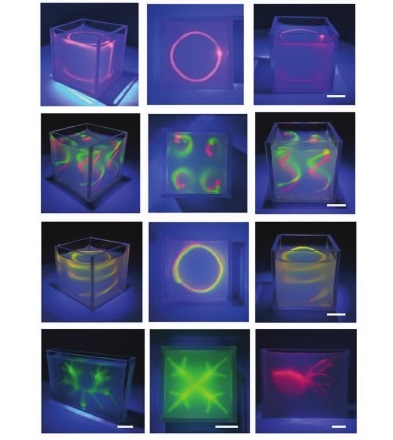

According to the researchers, aqueous or water-based microstructures are challenging to create, handle, and preserve as its surfaces are prone to shrink into spherical shapes with minimum surface areas. FREAL bioprinting has been designed to advance the bioprinting of complex tissue-like 3D constructs, including arteries, urinary catheters, and tracheae.

In an immiscible aqueous environment, all-liquid microconstructs are formed using aqueous bioinks which functions as a biocompatible support and pregel solution. Hydrogen bonding interaction is leveraged in FREAL between polymers in an aqueous two-phase system (ATPS), which can be stabilized for weeks. Furthermore, different cells can be separately combined with the bioinks and matrices created to obtain tailor-designed microconstructs with perfusable vascular networks.

Following experimentation, the team noted, “The formulated ATPS allows the continuous writing of all-aqueous 3D structures and ensures a sufficient stabilization time against breakup until the interfacial membrane can be formed.”

“During printing, if the ink viscosity is too large compared with that of the matrix, the extruded threads will be dragged by the printhead, comprising the printing fidelity. If the ink viscosity is too low to suppress the interfacial tension effect, the printed threads break up quickly.”

Accelerating regenerative medicine

Living cells can be directly mixed into the ink phase or matrix phase in FREAL printing. The researchers deduced that ATPS printing provides a suitable platform for viable cells. “The development of tissue engineering and regenerative medicine demands the 3D coculture of different cell lines. By using a dual-channel microfluidic printhead, different cells with controllable spatial distribution can be printed together.

“If the matrix phase is crosslinked, tissue-like constructs in which different cells of controllable compositions and densities are located in predefined spatial patterns can be fabricated. [However,] we notice that it would be difficult to thoroughly erase exquisite structures while keeping structures nearby unaffected.”

“Freeform, Reconfigurable Embedded Printing of All-Aqueous 3D Architectures,” is co-authored by Guanyi Luo, Yafeng Yu, Yuxue Yuan, Xue Chen, Zhou Liu, and Tiantian Kong.

For more additive manufacturing research, subscribe to our 3D Printing Industry newsletter and join us on Facebook and Twitter.

We also have jobs in the industry, visit our 3D Printing Jobs page to learn more.

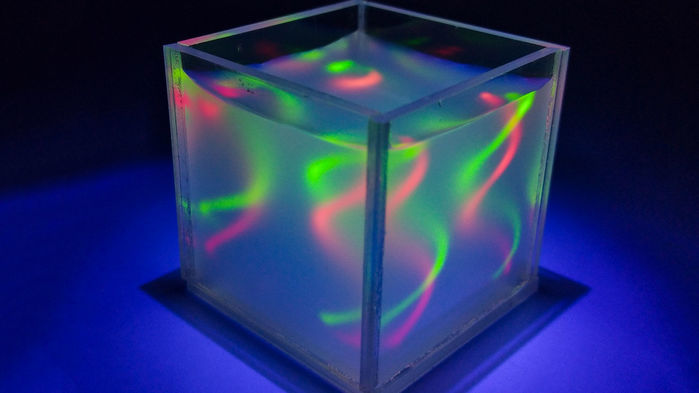

Featured image shows Aqueous structures created using FREAL printing. Photo via Shenzhen University.