Researchers at the University of Manchester in the UK have for the first time demonstrated the possibility of 3D printing freestanding objects with 2D material MXene. As the first study on the 3D printability of MXene, the team has developed an aqueous ink for extrusion of the material. MXene electrodes 3D printed are shown by experiments to have high capacitance and energy density. The electrodes can be used in energy storage devices such as supercapacitors.

3D structures from 2D materials

2D materials are also known as single-layered materials. When crystals are thinned down to one atom thick, unique physical and chemical properties emerge. The world’s first 2D material is graphene, discovered at the University of Manchester. While flexible, transparent and million times thinner than a human hair, graphene is also more conductive than copper and much stronger than steel.

Since isolated in 2004, graphene has opened doors for the exploration of other 2D materials. In 2011, MXenes, a class of ‘clay-like’ 2D materials composed of early transition metals (such as titanium) and carbon atom are first developed. Compared to graphene, MXenes have excellent electrical conductivity, hydrophilicity and high density.

To utilize such desirable properties, scientists need to efficiently integrate 2D materials into 3D structures and devices. The complex 3D architectures required, however, are hard to achieve using conventional techniques.

3D printing solves this problem while providing a high degree of architectural control, scalability and cost-effectiveness. Attempts at 3D printing graphene have been developed and applied to supercapacitor and rechargeable battery development. Taking a similar route, the remaining challenge for the team is to make inks with single to few layer MXene with the rheological properties required for 3D printing.

3D printing with MXene

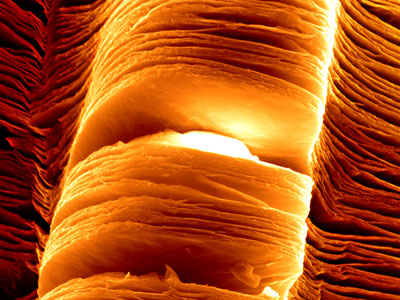

In the University of Manchester’s research, large MXene flakes of a few atoms thick (8 µm in average lateral size and 1 – 3 nm in thickness) are dissolved in water to formulate the 3D printing ink. Being hydrophilic makes MXenes to disperse in aqueous suspensions very easily, ideal for forming aqueous inks. Adopting extrusion-based 3D printing, the researchers chose the most studied MXene material, 2D Ti3C2Tx for its ideal viscoelastic properties.

“The inks we developed provide a good translation of properties from the 2D material into 3D, resulting in architectures with significantly improved specific surface area compared to other approaches,” said Dr Suelen Barg, lecturer in structural materials at the University of Manchester.

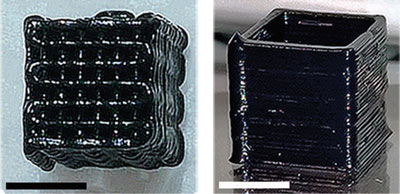

After 3D printing with micrometer-sized nozzles, the wet 3D structures are freeze-dried. Freeze-drying protects the internal integrity and the external shape of the structures with low shrinkage. This technique is capable of fabricating freestanding MXene architectures of over 20 layers tall with well-defined shapes and high specific surface area. Without additives or any further thermal or chemical treatments, microlattices and hollow rectangular prisms are directly 3D printed in the experiment.

Due to the excellent electrical conductivity of MXene, its potential to manufacture energy storage devices such as supercapacitors is of particular research interest. Supercapacitors can produce massive amounts of power while using much less energy than conventional devices. In the experiment, an interdigitated symmetric supercapacitor with a solid electrolyte was 3D printed with MXene. Both the electrode and current collector are 3D printed, thus eliminating the need to employ noble metals to be used as current collector in the electrode designs.

The 3D printed electrodes, with an active material loading of about 8.5 mg cm-2, exhibit a high areal capacitance of 2.1 F cm^-2, at 1.7mA cm^-2 and gravimetric capacitance of 242.5 Fg-1 at 0.2A g-1 with a retention of above 90% capacitance for 10000 cycles. They also achieve a high energy density of 0.0244 mWh cm-2 and a power density of 0.64 mWcm-2 at 4.3 mA cm-2.

“These results are among the highest in the literature and confirm that our synthesis and processing route allows an excellent translation of properties from the 2D material to the assembled 3D device,” pointed out Wenji Yang, the first author of the paper.

Applications of MXene devices

Potential uses for these MXene devices are for the automotive industry, such as in electric cars as well as for mobile phones and other electronics. In particular, 3D printed MXene architectures are particularly attractive for energy storage applications such as rechargeable lithium- and sodium-ion batteries, lithium-sulfur batteries and supercapacitors. They could also be used in other applications such as energy conversion, photocatalytic fuel production or electromagnetic shielding.

“The unique rheological properties combined with the sustainability of the approach open many opportunities to explore,” said Dr Suelen Barg, the supervisor of the research team. The group’s current research direction is optimizing their MXene ink formulations and additive manufacturing protocol to fabricate bespoke energy storage devices in asymmetric configurations. With the goal of overcoming the voltage window limitations and further enhancing the energy density, the team is also working on incorporating multi-materials printing and alternative electrolytes.

3D Printing of Freestanding MXene Architectures for Current‐Collector‐Free Supercapacitors discussed in this article is published online in Advanced Materials. It is co-authored by Wenji Yang, Jie Yang, Jae Jong Byun, Francis P. Moissinac, Jiaqi Xu, Sarah J. Haigh, Marco Domingos, Mark A. Bissett, Robert A. W. Dryfe, Suelen Barg.

For more of the latest research news subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook. Seeking jobs in academia? Make your profile on 3D Printing Jobs, or advertise to find experts in your area.