Oak Ridge National Laboratory (ORNL), Tennessee, and the University of Toledo (UToledo) in Ohio have signed a memorandum of understanding (MoU) agreeing to conduct research into the design and manufacturing of advanced materials for the automotive sector.

The two institutions will collaborate to gain new knowledge in the field of high-strength, and lightweight automotive materials. Research will cover areas such as additive manufacturing, monitoring and control systems, and process optimization. ORNL Director Thomas Zacharia comments:

“Our researchers push the boundaries of what is possible with materials and advanced manufacturing techniques.”

“By collaborating with university and industry partners such as the University of Toledo, national laboratories are able to move technologies into the marketplace where they will have the greatest societal impact.”

3D printing at ORNL

ORNL is sponsored by the U.S. Department of Energy, and conducts scientific programs that focus on materials, neutron science, energy, high-performance computing, systems biology and national security.

Many of its research activities and projects fall within the field of additive manufacturing. For example, ORNL has a $17.8 million agreement with British multinational manufacturer GKN Aerospace to develop aerospace parts using additive manufacturing. As part of the agreement, GKN Aerospace recently commissioned a new large scale additive manufacturing production cell at the ORNL.

The laboratory is also collaborating with leading industrial 3D printer provider ExOne to advance binder jet 3D printing technology. Working with ExOne, ORNL has developed a method for 3D printing aluminum-infiltrated boron carbide (B4C), a material used to make components for neutron imaging.

“ORNL is looking forward to providing access to its research facilities, along with expertise and guidance in advanced materials and manufacturing to the university in this valuable partnership,” explained Moe Khaleel, associate laboratory director for Energy and Environmental Sciences at ORNL.

As part of its automotive materials partnership, ORNL will leverage its expertise in additive manufacturing, as well as carbon fiber and composites, machining, energy storage and metrology. UToledo on the other hand will be bringing experience in manufacturing system modeling, metals engineering and assembly systems in order to research advanced materials for the automotive industry. Both partners will also consult members of the automotive industry in Ohio and Michigan.

High demand for lightweight materials in the automotive industry

Strong, lightweight materials continues to be a key focus of the U.S. automotive industry as it seeks to increase the energy efficiency of vehicles. This is particularly pertinent for hybrid electric, plug-in electric, and electric vehicles, as lightweight materials help to improve energy efficiency and increase range.

Advanced manufacturing techniques, like 3D printing, are set to play a significant role in the development of new processes for producing lightweight alloys and metals. ORNL and UToledo’s research will cover various areas relating to such techniques. These include the combination of shape-memory alloys with additive manufacturing, in order to create strong vehicle structures. Other key research areas surround monitoring and control systems for metal forming processes, and optimizing the joining techniques of high-strength materials such as steel, aluminum and composites. The research is expected to utilize the capabilities of ORNL’s Manufacturing Demonstration Facility and Carbon Fiber Technology Facility.

“We are proud to collaborate with Oak Ridge National Laboratory on this critical research to drive the next generation of automotive manufacturing,” concluded Dr. Mike Toole, dean of the UToledo College of Engineering. “Our partnership teaming together our innovative mechanical engineers at UToledo with some of the country’s preeminent scientists will focus on finding solutions to ensure the U.S. remains a global leader. The research will have spillover from the national level to the regional level.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

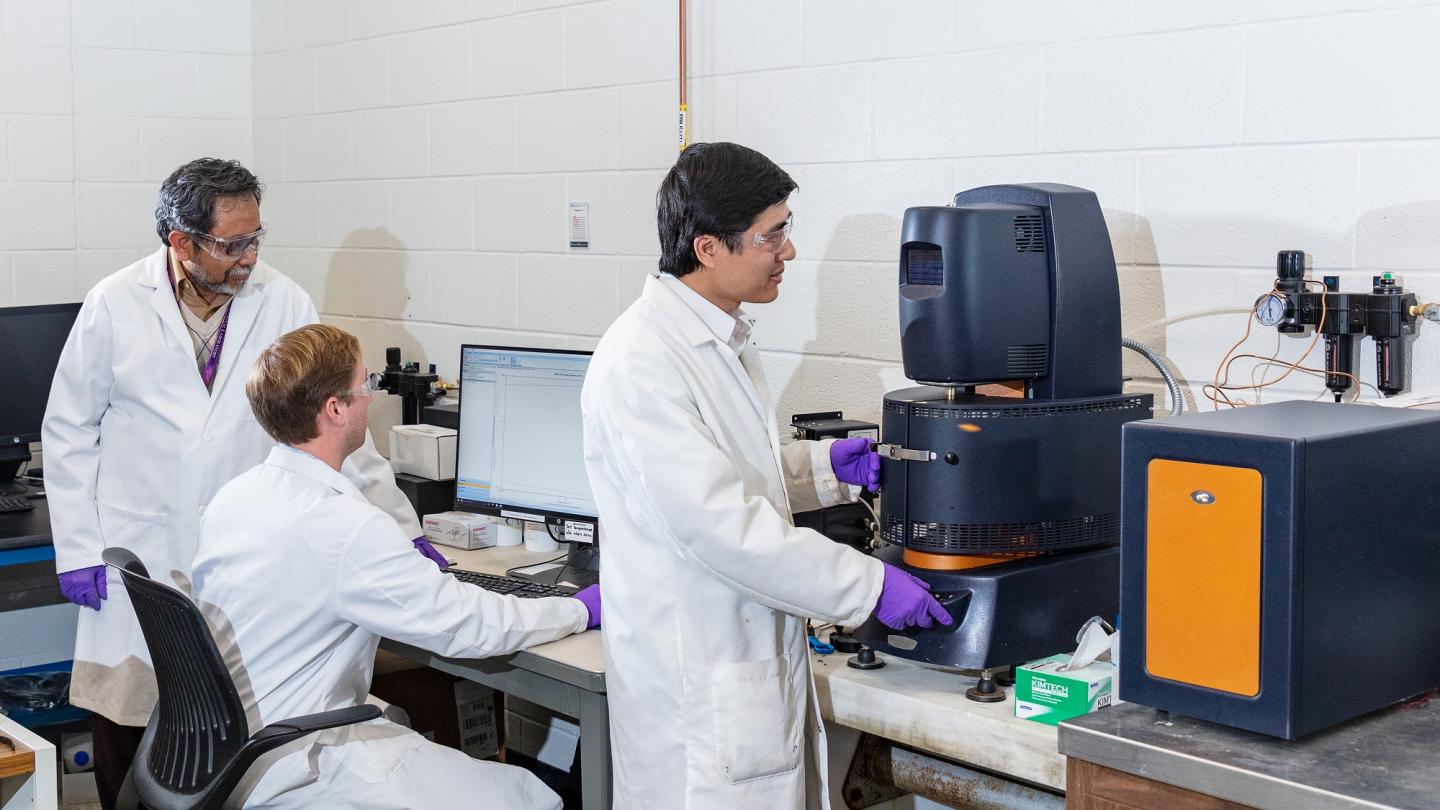

Featured image shows signing of the MoU between ORNL and The University of Toledo. Photo via University of Toledo