Equispheres, a metal additive manufacturing powder manufacturer, has reached an important milestone in its pursuit of superior quality materials.

Recently, the company received the results of a phase one test made by a third-party certification facility working in the fields of aerospace, space and defense. With a higher packing density than other materials on the market, Equispheres’ powder allowed for a 50% in production speed. Though higher production speeds were achieved the test also showed a 20-30% increase in a-basis mechanical performance.

“The uniform nature of our powder ensures that parts are produced with reliable and consistent mechanical properties,” comments Equispheres CTO Dr. Martin Conlon. “The minimal variance in our performance results provides design engineers the statistical confidence to produce stronger, lighter parts.”

Now the company is planning to introduce its powder to the market on a larger scale with the launch of a new equity financing.

Equispheres CEO Kevin Nicholds adds:

“The additive manufacturing industry has been struggling with slow production speeds and poor-quality feedstock. We are excited that our unique powder can help resolve both critical issues.”

Uniform, high performing metal powders

Headquartered in Ottawa, Ontario, Equispheres operates within Canada’s hotbed of metal powder manufacturing, joining Pyrogenesis and GE Additive’s AP&C that also operate within the region.

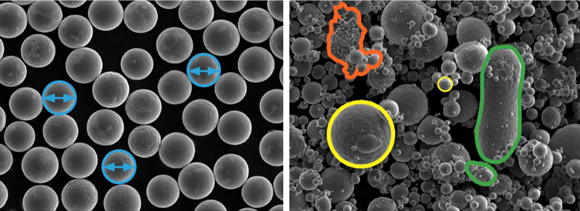

The company was founded in 2015, and is focused on creating “near perfect” powder of uniform size, sphericity, and microstructure for application in advanced manufacturing techniques like additive manufacturing and cold spray. By focusing acutely on the conformity of its powders, the company aims to overcome several challenges presented to these industries, relating namely to:

– Flowability and spreadability

– Packing and spread density

– Thin oxide layers and less water absorption

– Uniform melt and solidification of layers

– Design-allowable performance and,

– Safety

In additive manufacturing, a McGill University study recently proved that Equispheres aluminum alloy in particular is suitable for binder jetting.

Third party test results

The recent third party testing performed on Equispheres powders included a comprehensive sample of 3D printed material coupons. At a layer thickness of 60 μm, the coupons demonstrated an as-printed ultimate tensile strength of 449 ± 16 MPa, a yield strength of 272 ± 12 MPa, and an elongation of 6.4 ± 1.7 percent. With this validation, and a prior $5 million investment from Lockheed Martin, the company has ample support for adoption within the lucrative aerospace and defense sector. Accordingly, Equispheres has stated in a press release that it is “launching new equity financing to aggressively grow and unlock the vast potential of additive manufacturing.” Earlier in 2019, the company also attained an $8 million investment from early stage and SME financing bank BDC Capital after appealing to the firm’s cleantech initiative.

Commenting on this investment Susan Rohac, Vice President of Cleantech Practice at BDC, said, “Equispheres has an aggressive growth vision and is singularly positioned to scale in a rapidly expanding industry due to its novel, unrivalled product, strong management team and technical know-how.”

For all of the latest additive manufacturing materials news, subscribe to the 3D Printing Industry newsletter, like us on Facebook and follow us on Twitter. Create a profile on 3D Printing Jobs to find new opportunities near you.

Featured image shows uniform particles of Equispheres aluminum alloy powder. Image via Equispheres