Partnering with McGill University in Montreal, Canadian additive manufacturing powder producer Equispheres has announced the results of a research project on its aluminum alloy powders. Extensive testing, undertaken by the university, has revealed that the company’s powders are suitable for sintering with binder jet 3D printing technology.

Equispheres claims that the combination of binder jet 3D printing with aluminum alloy powder is an unprecedented achievement, and can have a significant impact on the automotive industry.

“We are excited about the industry response to our unique aluminum sintering results,” states Equispheres’ CEO, Kevin Nicholds.

“Although binder jet printer technology offers the speed and cost reductions necessary to enable additive manufacturing to meet the requirements of automotive mass production, the inability to print with aluminum alloys has been a major limitation to the technology – until now.”

Equispheres powder atomization

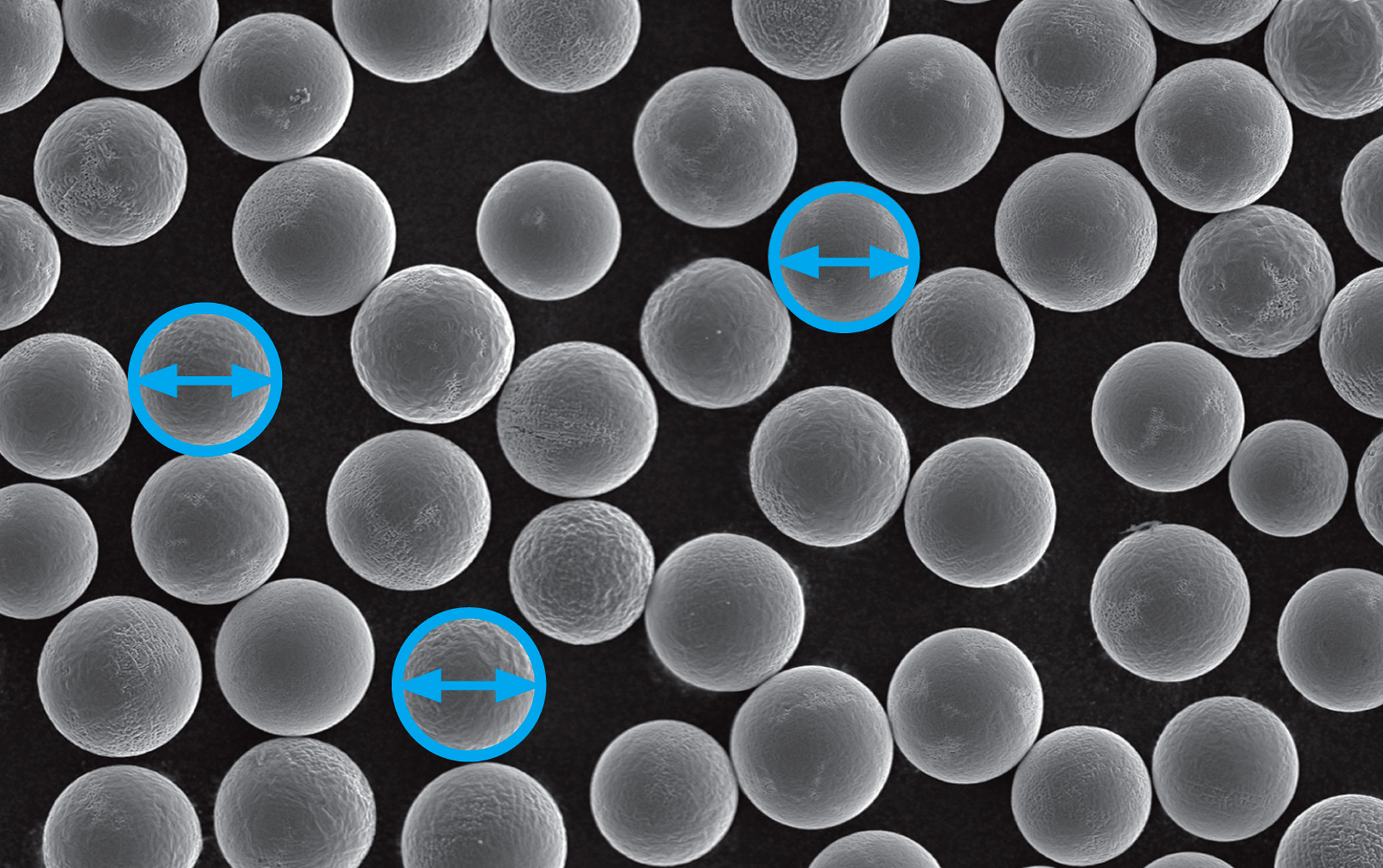

Headquartered in Ottawa, Ontario, Equisphere has developed a patent-pending method of powder atomization that creates near-perfect spherical metal powders. The uniformity and smoothness of these powders make them an excellent feedstock option for additive manufacturing systems, as heterogeneous particles can lead to quality discrepancies in the final part.

On the strength of its proprietary technology, Equispheres has previously received a $5 million investment from American global aerospace and defense company Lockheed Martin. The company also received an $8 million investment from early stage and SME financing bank BDC Capital, due to its focus on the environmental advantages of 3D printing. Namely, how switching to additive manufacturing can cut out the logistics middleman – reducing fuel consumption – and the technology’s “use-as-needed” material economy.

Combining the benefits of binder jet 3D printing with aluminum alloy powders

Binder jet 3D printers are said to be a hundred times faster than traditional laser based additive manufacturing machines and hold the key to enabling AM for mass production, according to Equispheres.

Although the process is able to work with steel, inconel and tungsten, binder jet has been unable to sinter aluminum alloys, an in-demand production material. McGill University’s test results suggest that now, binder jet 3D printing can sinter aluminum alloy with Equispheres’ powder. It can have a significant impact on the automotive industry, as reportedly over 30 percent of the sector’s material demand falls on aluminum alloy.

“The unique and tailored attributes of Equispheres powder have proven exceptional in compaction free sintering,”explains Dr. Mathieu Brochu, Associate Professor at McGill and Canada Research Chair in Pulse Processing of Nanostructured Materials. “We are excited to begin work with Equispheres’ binder jet printing partners in the next phase to fully understand all aspects related to sintering of complex shape components and the fundamental relations with new specialized binder agents.”

The specific results of the testing resulted in a compaction-free, sub-solidus sintering of Equispheres’ standard AlSi10Mg aluminum alloy powder, with densification levels of over 95 percent and an excellent microstructure. Currently, Equispheres is collaborating with key partners to develop specialized binder agents that are required for aluminum and for specific automotive applications. As the company continues to refine and test its powder with binder jetting technology, it aims to position the process as a new standard for the production of critical parts.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows comparing metal powders. Photo via Equispheres.