This Valentine’s Day, why not warm the cockles of your heart with fun, animated short film about love, made possible with 3D printing? Below is a flick, produced by GoEngineer and Tandem Motion Picture Studios, depicting the story of one lonely robot who discovers love during the after hours of a 3D printing design studio. So, if you’ve ever wondered what happens when an FDM 3D printing shop shuts down for the night, look no further.

To make a clever and cute film such as “SHeLvEd” is no easy endeavor. Before actually filming, the CEO of GoEngineer, Brad Hansen, along with Tandem Studios President Nathan Smith and GoEngineer engineers Tyler Reid and Kevin Lynk had to answer such questions as what the storyline of the film would be, who would star in it, and what sort of tone it would have. Next, Reid and Lynk had to design and print their characters, in a way that would suit the needs of a stop-motion video.

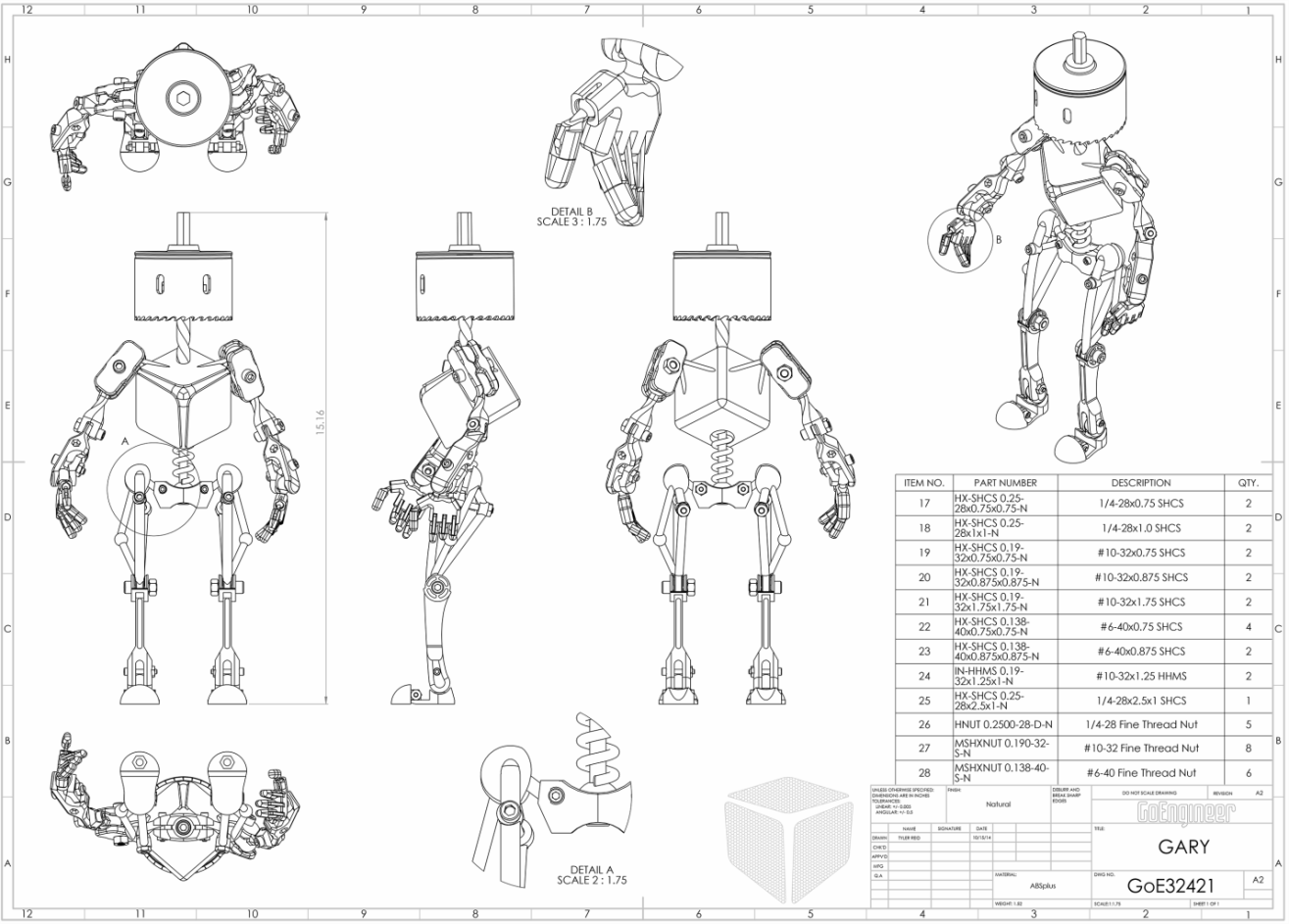

In the end, the male robot, whom they referred to as “Gary, was 3D printed on Stratasys machines with 33 different joints capable of bending and twisting numerous times for each frame of the animation. During the design process, some parts underwent up to 6 design iterations. For instance, Gary’s thigh required four design revisions in order to ensure that the hip and ball joint could hold support Gary’s weight.

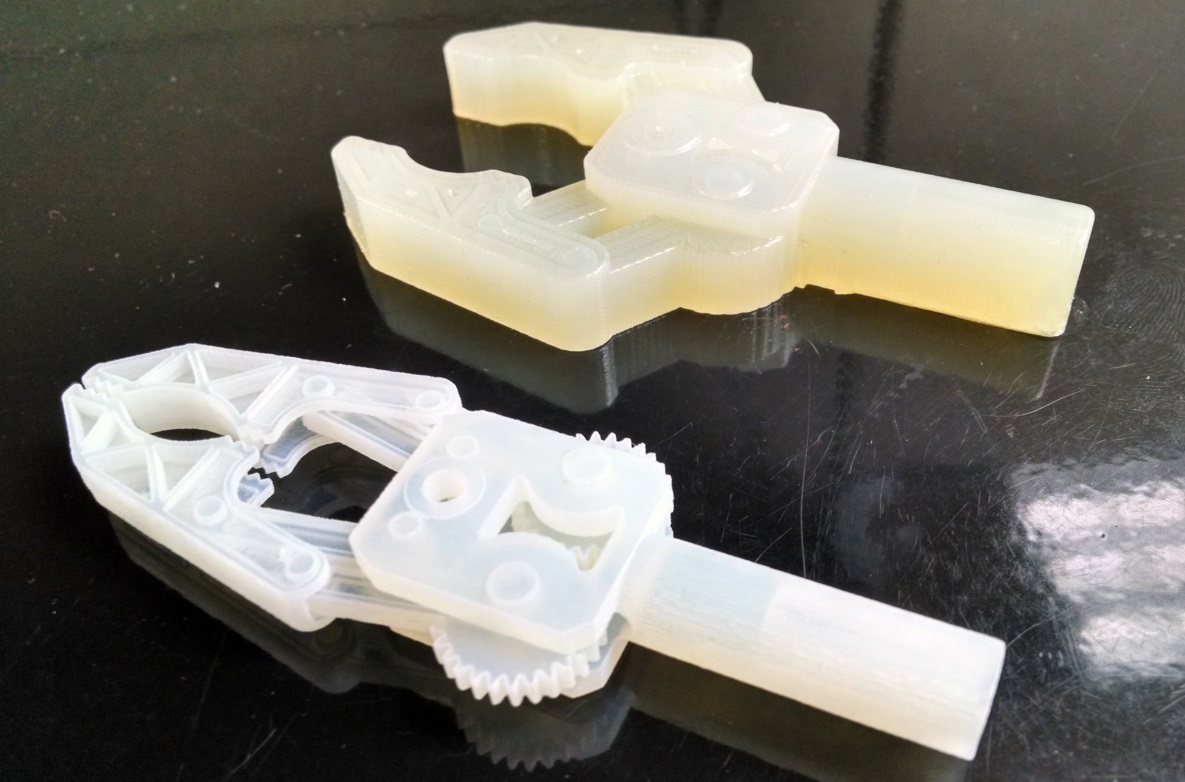

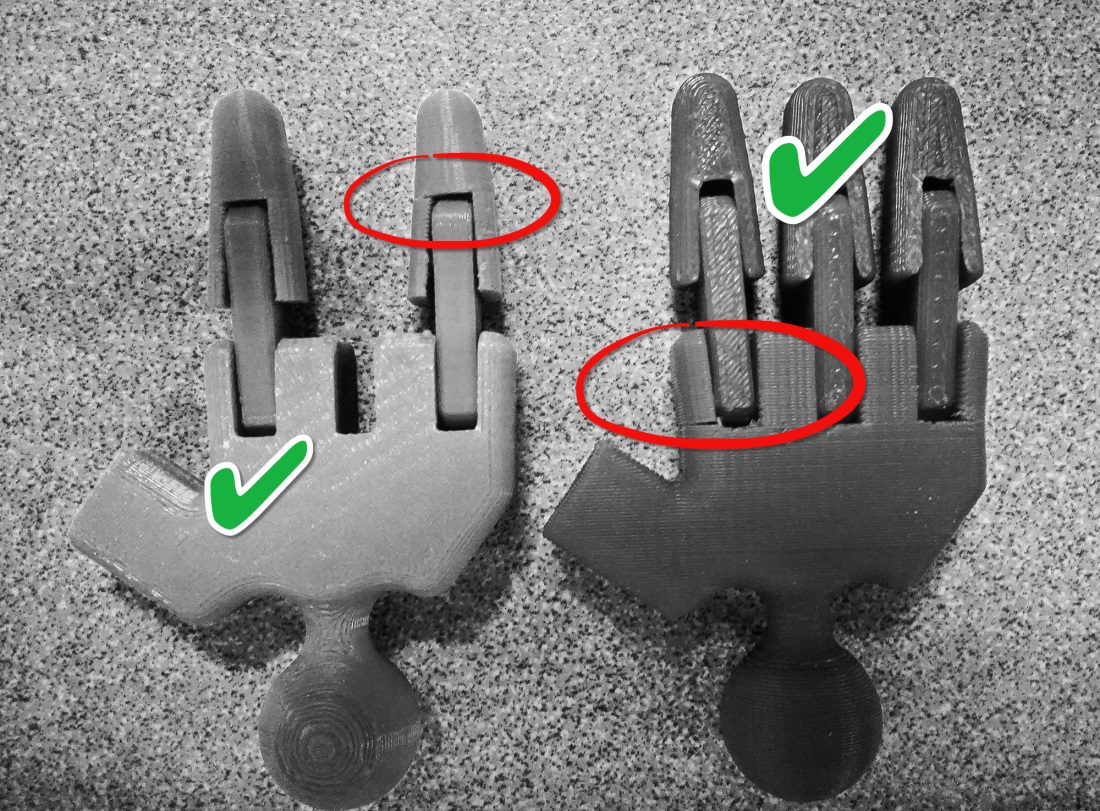

For the majority of the parts, however, a Fortus 250mc did the printing, while a uPrint SE Plus and Fortus 400mc were also used, particularly for some of the larger components. In fact, Gary stands at 16” tall. Orienting the parts for printing, however, had certain limitations. Reid explains in a blogpost, “When it came time to print the parts, careful consideration of the print orientation was needed. With FDM printing, vertical walls look the best and parts are strongest parallel to the layers. For some parts we had to balance aesthetics and strength – the parts had to look good for the camera and withstand the rigors of filming. With the palms for example, our original prints (oriented for best aesthetics) had to be reprinted (oriented for highest strength) after the snap-fit caused the plastic to crack.”

Filming the short was left to the Tandem Studios team, who photographed the GoEngineer Salt Lake City print lab from all angles, before filming the actual animation in front of a green screen. Then, in post production, the stills from the print lab were super-imposed to bring the setting to life. Over the next couple of months, 3200 stills and 700 hours of filming and editing were transformed into the 5-minute-long film you see above. Not bad for a 3D printed love story, eh? In fact, I’d say that Gary and his gal deserve a full-length feature film.