3D printing news can move pretty fast, here is a quick digest of some recent stories you may have missed.

Metal for the masses

3D printing metal is a relatively small percentage, by installed base, of the additive manufacturing market. With industrial machines reaching prices of $4m, the cost is obviously prohibitive for most. While 3D printing with thermoplastics using FFF and SLA methods has become more affordable since key patents expired, this pattern has not been seen in the metal world yet.

3D printing with metal is undeniably more complex than using PLA or ABS, however as the underlying components (such as lasers) and the core IP becomes more accessible a number of projects are beginning to reach the market. One such project comes from advanced engineering research lab, Fraunhofer and Dawid Ziebura, Project Engineer at Fraunhofer ILT will demonstrate a Selective Laser Melting (SLM) system available for less than €30,000 at next week’s Formnext show in Frankfurt.

Gif shows one of Fraunhofer industrial Laser Metal Deposition machines, via FraunhoferILT on Youtube.

Getting things done, can 3D printing help?

Thibaut de Vylder is the CEO of dFakto and he thinks that a combination of 3D printing and virtual reality could unlock, $3.3 billion in cost savings according an interview with Forbes.

dFakto have created an app to visualize data and workflows, allowing the user to experience charts in an immersive way. But what happens when the goggles come off? That is where 3D printing enters the equation, with a print out of your to-do list.

“It allows people to touch what they do. Otherwise when you close a report you don’t see it anymore … but this remains on my desk,” said de Vyler.

Experience 3D printing toy playhouse in South Korea

If you still have room on your desk after 3D printing out an Excel workbook, then Korea’s Sem Games would like you to add one of their 3D printed toys to your optimized workspace.

The company have opened a pop-up store in Seoul’s Hongdae district to “enable simultaneous offline toy design/assembly and online games” according to the Korea Herald.

Cocking a snook at copyright, Sem Games invite visitors to make their own toys, one possibility is “combining the body of Batman with the head of Astro Boy.” CEO Ahn Jeong-hoon explains, “The PLAP service will be attractive to not only children, but single people in their 20s and 30s who enjoy toys as a hobby. If our first store is successful, we plan to open a second store in Pangyo next year.”

3D printing’s not dead

As the days grow shorter summer seems a long time ago, and now the seasons have changed some analysts are also changing their minds about the state of 3D printing. Over the summer, a torrent of articles proclaiming the death of 3D printing sprang up as reporters sought to fill websites.

An article on business orientated website Inc. about, “the slow sad and ultimately predictable decline of 3D printing” encapsulated many of the misunderstandings around the desktop 3D printing market, and predictably enraged many industry experts. Now, writing on investment focused website, The Motley Fool, professional investment advisor Tim Bruger says, “it’s clear the negative headlines surrounding the burgeoning marketplace that still occasionally crop up are incorrect.”

Although primarily discussing HP’s entry into the market, Bruger acknowledges that the “278,000 desktop 3D printing” units sold are significant.

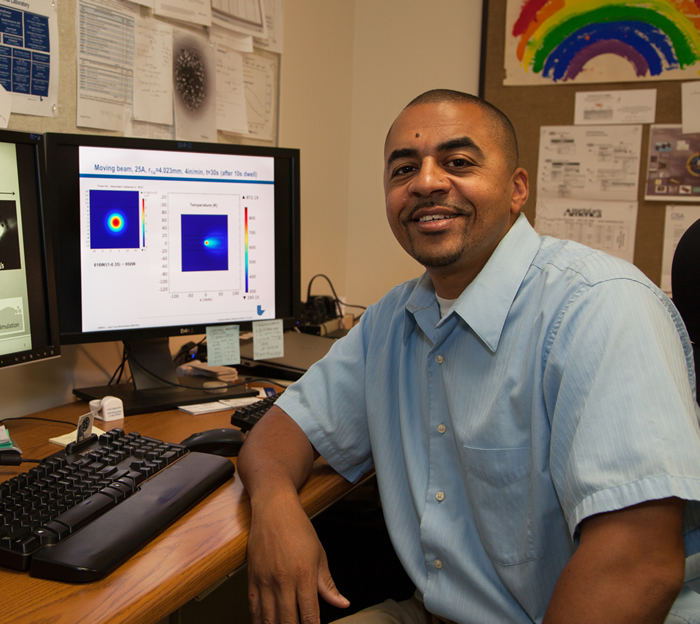

Lawrence Livermore’s Ibo Matthews elected as OSA fellow

The LLNL principal researcher who recently published research aiming to hasten the adoption of metal 3D printing by industry and improve quality and speed has been recognised by the Optical Society (OSA).

Ibo Matthews’ election to the OSA is for his, “outstanding contributions and sustained leadership in the field of high-power laser-induced damage science, laser-material interactions and processing, and vibrational spectroscopy-based materials characterization.” Congratulations!

And finally..

If you’re packing for Frankfurt this weekend and preparing to visit Formnext why not remind yourself with a refresher from last years event here. Of course 3DPI will be in Germany next week to report on the latest news in our industry, so be sure to say hello.

Featured image shows the Sliced logo over ‘Structuring process for glass using direct laser ablation with ultrafast laser pulses’ from Fraunhofer ILT, Aachen / Volker Lanner. Image via: nanobay