It feels a little strange to write that about visiting a manufacturing show in Frankfurt in late Autumn and that show not being Euromold. Both organizations, Frankfurt Messe and Demat decided to part ways for many complex reasons that we are not going to analyze in detail here (money).

As is often the case when you leave the old road for the new one, you know what you leave behind but you don’t know what you are going to find. In many cases it takes a long time to go back to a new “normality”. This is definitely one of those cases, even though it seems safe to say that a change in direction was necessary.

While Euromold represented an ending and a maybe new beginning for a show that had dominated the manufacturing industry for twenty years – and as such reflected a feeling of nostalgia for better times – the “zero edition” of Formnext seems like the beginning of something entirely new and good, but still just the beginning. In the end the number of exhibitors and visitors – although we are still on the first day – don’t seem all that different, other than the fact that all the biggest metal manufacturers are here at Formnext and were not at Euromold (except for Sisma, with a stylish new stand).

However there are many other industry players missing, especially the 3D scanner manufacturers (that were massively present at Euromold). In my opinion running two different shows, not so temporally far apart, is not beneficial for the industry as a whole, both for the more limited number of visitors that either show is able to attract and for the lesser amount of networking possible among industry players. The proof is that Euromold barely filled three small halls in Dusseldorf while Formnext only filled one hall (Halle 3) at Frankfurt Messe.

Formnext comes at a time when the AM industry had to reinvent itself yet again after bursting of the latest Gartner-predicted hype bubble. We are now on the low-end of the new-tech enthusiasm hype spike for consumer 3D printing and at the beginning of the organic growth curve for industrial 3D printing. This means that the 3D printing industry as a whole can only grow from here and – if properly supported – Formnext can grow with it.

While it does not yet have its very own identity, the show already stands out for a younger and more modern approach, starting from free Wi-Fi availability for all participants and visitors, something not to be taken lightly for a show that wants the media to talk about it. Any AM industry show can no longer just be about selling stuff and making deals – like any manufacturing show – but it needs to spread awareness and enthusiasm among the public as well. Several more free services, including free admittance for all and a free coat-room may not make the difference but certainly contribute.

So who are the companies that have accepted this bet from Formenext? First of all Stratasys, which is taking its role as industry leader very seriously. While the company has been through some difficult times – at least from an image point of view – it must not be forgotten that its revenues are almost for times as much those registered by industry “darling” EOS and other big players, growing rapidly, such as Concept Laser and Envisiontec. Not to mention the other, newer players such as Prodways, Formlabs, Zortrax, the newest entry in SLS Ricoh, and Roboze (more on them tomorrow). Stratasys made sure no one forgot that, by setting up the biggest stand in hall 3 and throwing a big party at the end of the day for industry players network.

During his press conference, Stratasys CEO David Reis further emphasized the company’s growth potential in what Stratasys sees as a still largely unexplored rapid prototyping market (estimated at $10-15 billion with only about 20% covered so far by AM) as well as in custom tooling, as demonstrated by the newly announced high-profile partnership with German auto manufacturer Opel. Under the new, simplified and styled-up logo, Stratasys has been organizing and streamlining all its activities (3D printer manufacturing, 3D printer reselling, 3D printing service, consultancies and consumer/educational) into one single entity to better face the challenges ahead.

Whether because of the recent internal turmoil or for other reasons, 3D Systems kept its stand at a minimum, limiting it to a display of 3D printers, so the next largest stand on the show floor was EOS’, reflecting the company’s relevance in the global AM scenario. The German SLS and DMLS 3D printer manufacturer had made several announcements on the day before the show (as Mike reported yesterday). EOS is undeniably a model to follow for taking 3D printing from prototyping into actual manufacturing.

Among the pure metal manufacturers present, one of the biggest news came from Trumpf, that presented the new, huge metal fusion 3D printer based on the joint venture with Sisma, as well as its new laser metal deposition 3D printer that had been pre-announced a few days ago. Sisma also showed off its precious metal additive manufacturing capabilities (see below), as well as Industrial and Dental capabilities of its different MySint machines, including the new large size one created through the joint venture with Trumpf. Jewelry is a rapidly growing segment, with competition intensifyng between EOS, through the Cooksongold partnership (and the Preciouos M80), Realizer, with the Progold partnership, and Concept Laser.

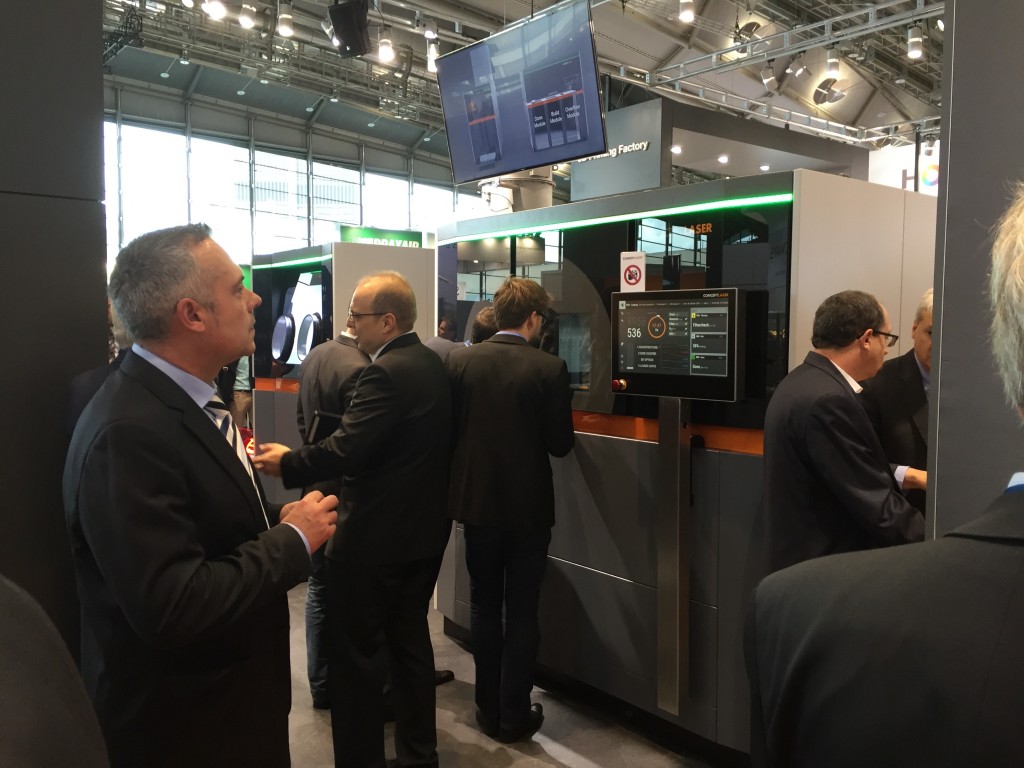

Concept Laser also stood out by presenting an entirely new 3D printer architecture for a fully automated, modular, additive manufacturing factory. The new machine, which does not even have a name yet, is ultra futuristic looking and it is meant for the future of manufacturing since it will not be available for at least another year. It integrates four lasers and fully automated components for powder and production management. Furthermore, the cleaning station will now be a separate module since this system is meant for a factory space where several machines can rely on a single cleaning station. We are certainly going to cover this system more in depth in the upcoming days.

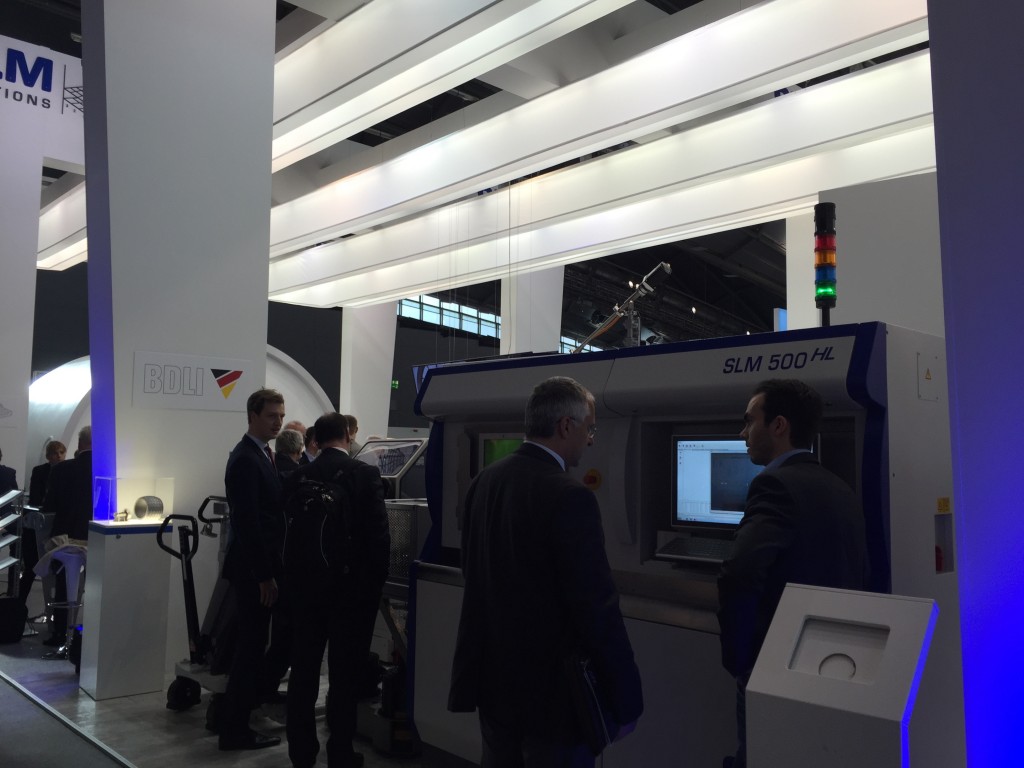

Matsuura, Arcam and SLM Solutions basically continued to give a display of their evolving AM capabilities, with the German company in particular showing off the upgrade version of its largest 3D printer. The new SLM500HL now integrates four lasers which possibly makes it the fastest SLM based system on the market at this moment.

One the most interesting new approaches was that introduced by Additive Industries: a fully automated metal AM 3D printer with multiple job capabilities. The company had invited several journalists to visit their HQ in Eindohoven to sse the new modular production system with automated 10X storage capabilities. At the show visitors to the stand were treated to a breathtaking Oculus Rift video showing off the concept of the “lights-off, fully automated, serial additive manufacturing factory of the future, a recurrent concept at Formnext.

In fact other companies presenter their own idea for an approach to the complete production cycle, from digital file to finished product. for example Renishaw presente a very pratical approach which starts from its new, faster RenAM 500M machine (available sometime next year) and leverages on the new QuantAM file preparation software, as well as all the other measurement, milling and control machines it produces, to automate and streamline the component production manufacturing process.

The bottom line is that most of the world’s biggest metal AM 3D printer manufacturers were present at Formnext and this means that they intend to work together to carry the industry forward. The vision is there and the industry has now set its eyes on full, serial production. On the other hand there were not many manufacturers of 3D scanners, photopolymer 3D printers and low cost filament 3D printers present. Getting everyone on the same page, I think, would be a benefit for all.