Voting shortlists for the 2021 3D Printing Industry Awards are now open. Who do you think should receive top honors this year? Have your say now.

Interested in tuning in? The Youtube livestream link is also live, so viewers can now subscribe and set reminders to ensure they don’t miss out.

SLS 3D printer manufacturer Sintratec has released a software update that is designed to help manufacturers optimize the way they pack their system’s build volume during production.

Launched as an upgrade for the firm’s Central Software, the nesting add-on uses an algorithm to automatically arrange parts within the build volume of Sintratec’s S2, enabling the machine’s users to achieve the best possible packing density.

In doing so, the company’s CTO Christian von Burg says the nesting update allows adopters to optimize their throughput from every print run, making the current “puzzle” of manually placing parts “a thing of the past for Sintratec customers.”

“No other program on the market is capable of nesting 3D parts as densely in such a short time as ours,” explained von Burg. “The Sintratec Nesting Solution therefore marks a milestone on the path towards efficient additive manufacturing and is a real game changer in the field of selective laser sintering (SLS).”

“With the addition of a 3D nesting function, we are taking our software to the next level.”

Sintratec’s scalable SLS approach

Since being founded in the Swiss town of Brugg in 2014, Sintratec has established a strong portfolio of compact SLS 3D printers and integrated peripherals. Although the firm launched its low-cost Sintratec Kit five years ago for just €5,000, the product remains part of its core offering for prototyping clients, and it continues to address the needs of users in the medical, industrial and education sectors.

Alongside its entry-level Kit system, the company also markets the Sintratec S2, which is specifically designed to allow users to scale their operations as their businesses grow. Composed of a Laser Sintering Station, Material Core Unit and Material Handling Station, the S2 offers adopters a uniquely self-contained solution that enables them to switch seamlessly from one process step to another.

In the past, Sintratec’s scalable system has often found automotive applications, with Daimler installing the machine at one of its Bavarian branches to 3D print bus and truck spares in 2019. Similarly students at ETH Zurich have previously designed a functional electric motorbike using the firm’s software, an offering which it is now upgrading with the aim of “opening completely new possibilities for AM.”

Automated nesting optimization

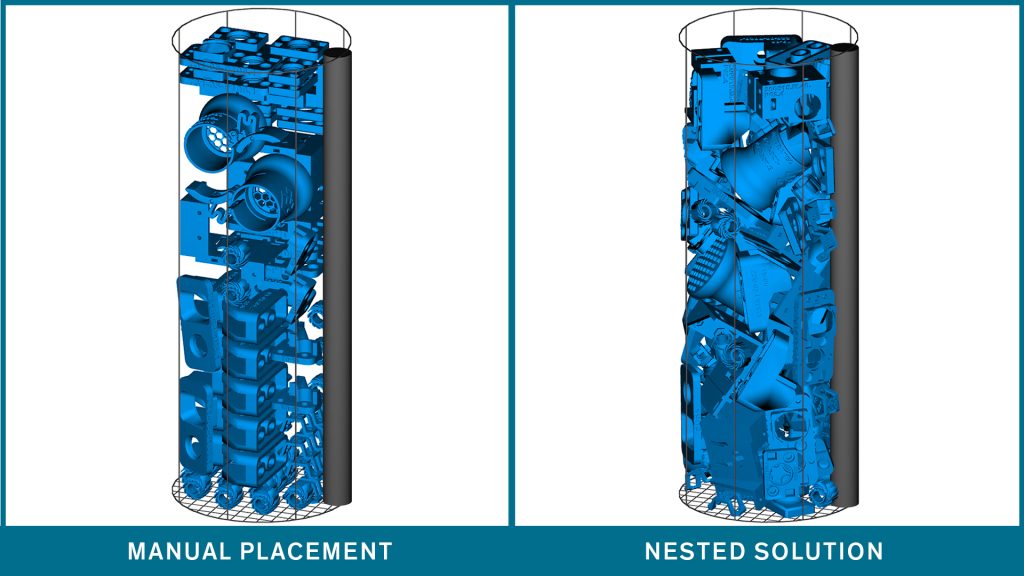

At present, SLS 3D printing often requires users to manually place models inside a machine’s build volume prior to entering production, to optimize the number of parts yielded by each batch. According to Sintratec, however, this time and material-intensive process can lead to “mediocre results,” thus with its new update the firm has committed to automating this element of print preparation.

Leveraging the firm’s software upgrade, users can now simply import their 3D models into Central, and the nester will analyze and distribute these parts to achieve optimal print results. Adopters can even select different configurations to achieve their project-specific goals, allowing them to choose between going all-in on packing density, or focusing on attaining a desired component orientation.

Thanks to the software’s in-built algorithm, Sintratec says it is able to conduct these calculations more quickly than its competitors, while realizing “new standards in packing density.” Elsewhere, to exhibit the throughput unlocked by its update, the firm has carried out print runs of nine test models, finding that the software upped its output from 78 to 114 parts, reducing their aggregate cost from $5.75 to $3.79.

When deployed over the course of 100 print jobs, the company estimates that its nesting solution could save adopters as many as 50 working hours, 47 kg of powder and 800 hours of printing time. To give all its customers the opportunity to harness these potential benefits, Sintratec has made the upgrade free of charge for the first year to all S2 adopters, with annual licenses costing €1,490 from then on.

3D printing’s nesting solutions

Given the time-consuming nature of manual build volume organization, it’s hardly surprising that developers are beginning to upgrade the nesting features of their software offerings. In December 2020, CoreTechnologie added a new nesting function to its 4D_Additive program, which utilizes ML algorithms to provide users with an evenly-arranged build volume.

Likewise, Link3D launched a True Shape Nesting update back in 2019 that was designed to help users find an optimal nesting strategy based on the shape of any given 3D model. Compatible with both MJF and SLS machines, the new and improved program allowed adopters to utilize any orientation for parts, including the Z-axis.

Sintratec’s more direct competitor, Sinterit, has also launched a new version of Studio, its dedicated software offering, which includes a number of upgrades. Most significantly, the update has introduced an ‘auto-nesting’ feature that auto-arranges users’ parts on the build plate in an optimized formation, potentially unlocking higher model throughputs.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

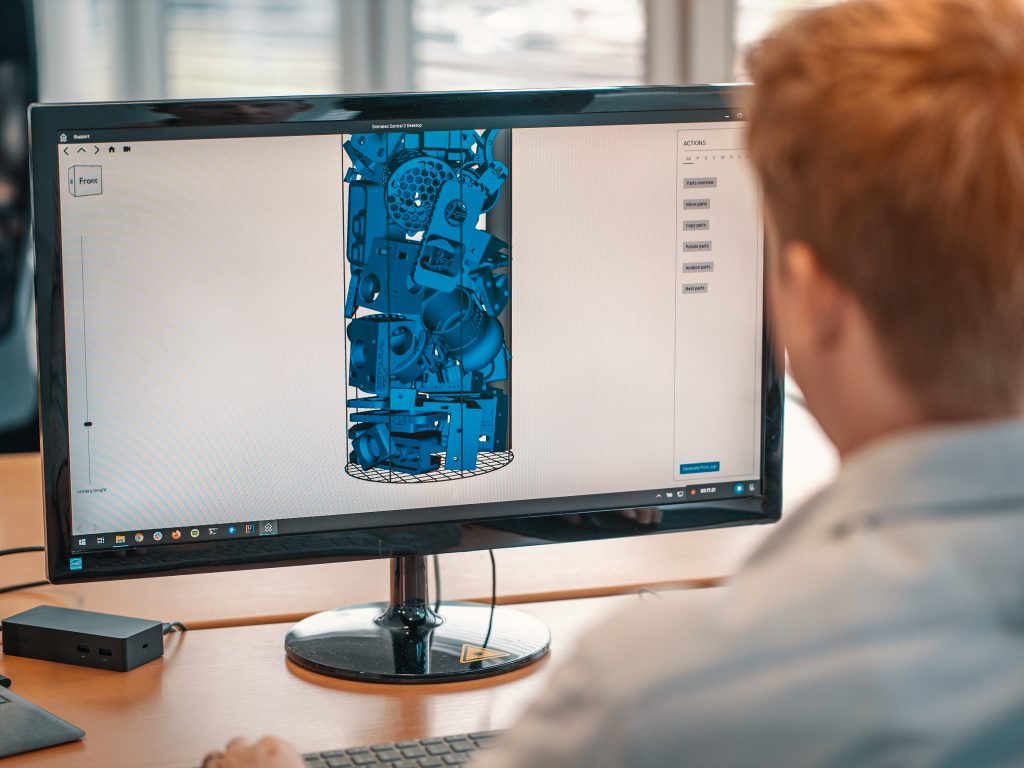

Featured image shows an engineer using Sintratec’s updated software to nest parts in a 3D printer’s build volume. Photo via Sintratec.