3D printer manufacturer Meltio has integrated ESPRIT TNG hybrid manufacturing CAM software from Sweden-based global technology company Hexagon into its Meltio Engine system.

Through the deal, Hexagon becomes the first hybrid manufacturing software partner for the Meltio Engine and furthers the system’s hybrid manufacturing capabilities for parts produced via a combination of direct energy deposition (DED) and machining.

“The Meltio DED Technology provides a tremendous advantage for users who want high-quality AM processes without the high capital investment in new machinery,” said Clément Girard, Product Manager responsible for Additive Manufacturing CAM at Hexagon’s Manufacturing Intelligence Division.

“Meltio has already provided equipment to Hexagon and our engineering teams are working together to deliver the best turnkey post-processor for supported CNC systems.”

The Meltio Engine

Hybrid manufacturing combines both additive and subtractive manufacturing methods, such as CNC machining, in order to broaden the possibilities of near net shape manufacturing, prototyping, repair, and feature additions.

Hybrid manufacturing also enables the application of different 3D printing materials to the same part, while offering a more cost-effective option for manufacturers looking to adopt 3D printing without the large initial capital investment in machinery.

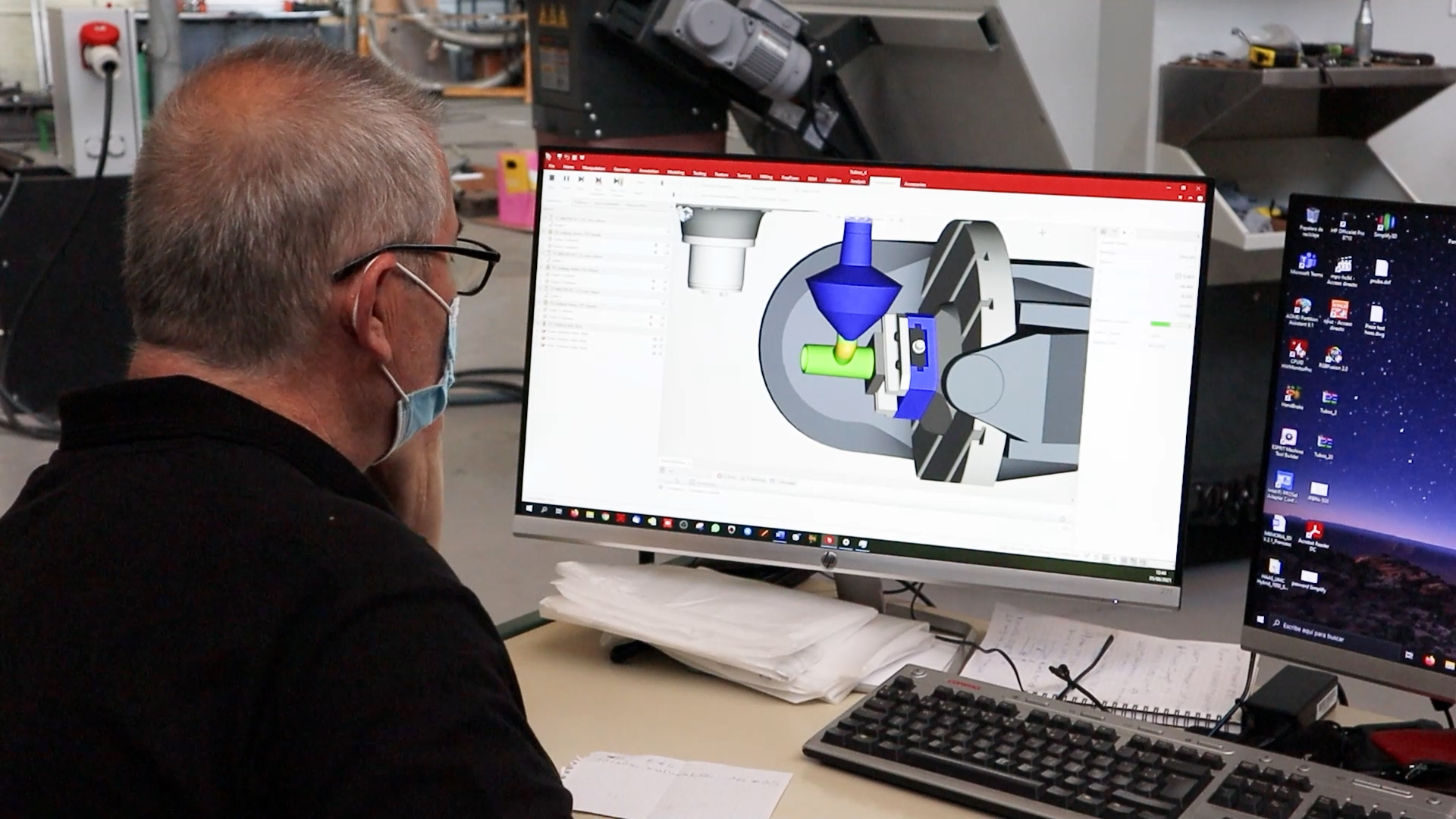

The Meltio Engine is an advanced control module for fitting existing CNC machines, robots, and gantry systems with Meltio’s 3D printing technology. The system was initially presented at Formnext 2019, and is designed to transform any motion platform into a hybrid metal 3D printing system.

The Meltio Engine is powered by the firm’s own take on the DED process, its proprietary wire and powder-compatible laser metal deposition (LMD) technology, which also operates its M450 3D printer. Essentially, the system intends to fuse the benefits of LMD with large-format control systems in order to enable “previously unseen” scales of metal parts production. Meltio unveiled the latest version of its Engine in November 2020, which featured a number of upgrades to improve the affordability and accessibility of hybrid manufacturing for metal parts.

Since then, the firm has partnered with Phillips Corporation to integrate its 3D printing cell into various Haas Automation CNC machine tool platforms in order to form the Phillips Additive Hybrid manufacturing platform. The combination of Meltio’s 3D printing technology and Haas Automation’s traditional machining capabilities aims to provide a more cost-effective means of producing and repairing metal parts using a single machine.

Most recently, industrial machine shop Sivó became the first in Spain and Portugal to integrate the Meltio Engine into its operations. The firm will leverage the system to improve its glass mold repair process and complete a project that has been in the works since 2016.

Streamlining hybrid manufacturing workflows

Through its latest partnership with Hexagon, Meltio is seeking to streamline the additive and subtractive manufacturing workflows for users of its Meltio Engine system. By integrating Hexagon’s ESPRIT TNG CAM software into the platform, the firm hopes to offer machine shops a single interface for preparing and programming hybrid machining and DED 3D printed part production.

ESPRIT TNG is a hybrid manufacturing CAM software for CNC programming, optimization, and simulation of both additive and subtractive processes. The software’s Additive for Direct Energy Deposition capabilities will allow users to benefit from side-by-side additive and subtractive programming, stock-aware cycles, and the ability to fully simulate both processes.

By offering users an “advanced but easy-to-use” hybrid manufacturing workflow in a single tool, Meltio hopes to enable more manufacturers to leverage hybrid manufacturing in order to better compete in the global market.

According to the firm, the combination of additive and subtractive processes can allow for a rapid and more cost-effective reaction to fluctuating market needs with faster lead times, while also opening up greater possibilities regarding the design, weight, and strength of metal parts.

Meltio and Hexagon are holding a joint webinar on 4th November to demonstrate the capabilities of the hybrid manufacturing software workflow.

The rise of hybrid manufacturing

Hybrid manufacturing systems offer numerous advantages to manufacturers, such as the ability to leverage different materials for the same part in a single machine. The hybrid manufacturing approach also gives manufacturers a more cost-effective means of adopting 3D printing technologies without the large initial capital investment in machinery.

Last year, an eight-partner research project for the development of a highly efficient modular hybrid manufacturing cell commenced. The project is combining a multi-axis KUKA robotic arm with an LMD toolhead in order to make it easy to integrate into existing process chains.

Elsewhere, CNC grinding machine manufacturer ANCA developed a hybrid 3D printing system for manufacturing custom-designed machining tools, and hotend manufacturer E3D launched a subtractive toolhead for use with its Motion System and ToolChanger, called the ASMBL tool.

More recently, hybrid subtractive-additive systems specialist Hybrid Manufacturing Technologies (HMT) announced it is spearheading an R&D project to fast-track the development of a new compact wire-feed system for laser-based 3D printing, which it will integrate into its KUKA robotic cell. Named ‘FastWireAM’, the project is backed by a grant from the UK’s technology accelerator Innovate UK.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows a hybrid manufacturing setup with ESPRIT software and the Meltio Engine. Photo via Meltio.