Hybrid subtractive-additive systems specialist Hybrid Manufacturing Technologies (HMT) has revealed that it’s spearheading a new R&D program called ‘FastWireAM.’

Backed by the UK-based technology accelerator Innovate UK, the project is designed to fast-track the development of a new compact wire-feed system for laser-based 3D printing. Once the new DED design is ready, HMT will work with consultancy firm TWI and wire feedstock producer Epoch Wires, to optimize its performance, and accelerate its market uptake.

Optimizing wire-fed 3D printing

During the research program, HMT is set to collaborate with Epoch to build the new system at technology firm TWI’s Yorkshire base. The British company will integrate the device into its KUKA robotic cell, through which it plans to conduct process optimization and performance mapping tests on a purpose-built demonstrator.

After the system’s capabilities have been validated by TWI as an independent third-party, the companies will 3D print a selection of industrial case study components. Using these prototype parts, HMT ultimately aims to demonstrate the benefits of 3D printing with its proprietary interchangeable head over existing DED technologies.

Epoch’s participation also has a marketing element to it, as it intends to exhibit the “added value” that clients can expect to gain via its powder-cored wire feedstock. Although the partners haven’t yet set the project’s completion date, they have gained an Innovate UK grant, which should accelerate the device’s development.

HMT’s hybrid manufacturing approach

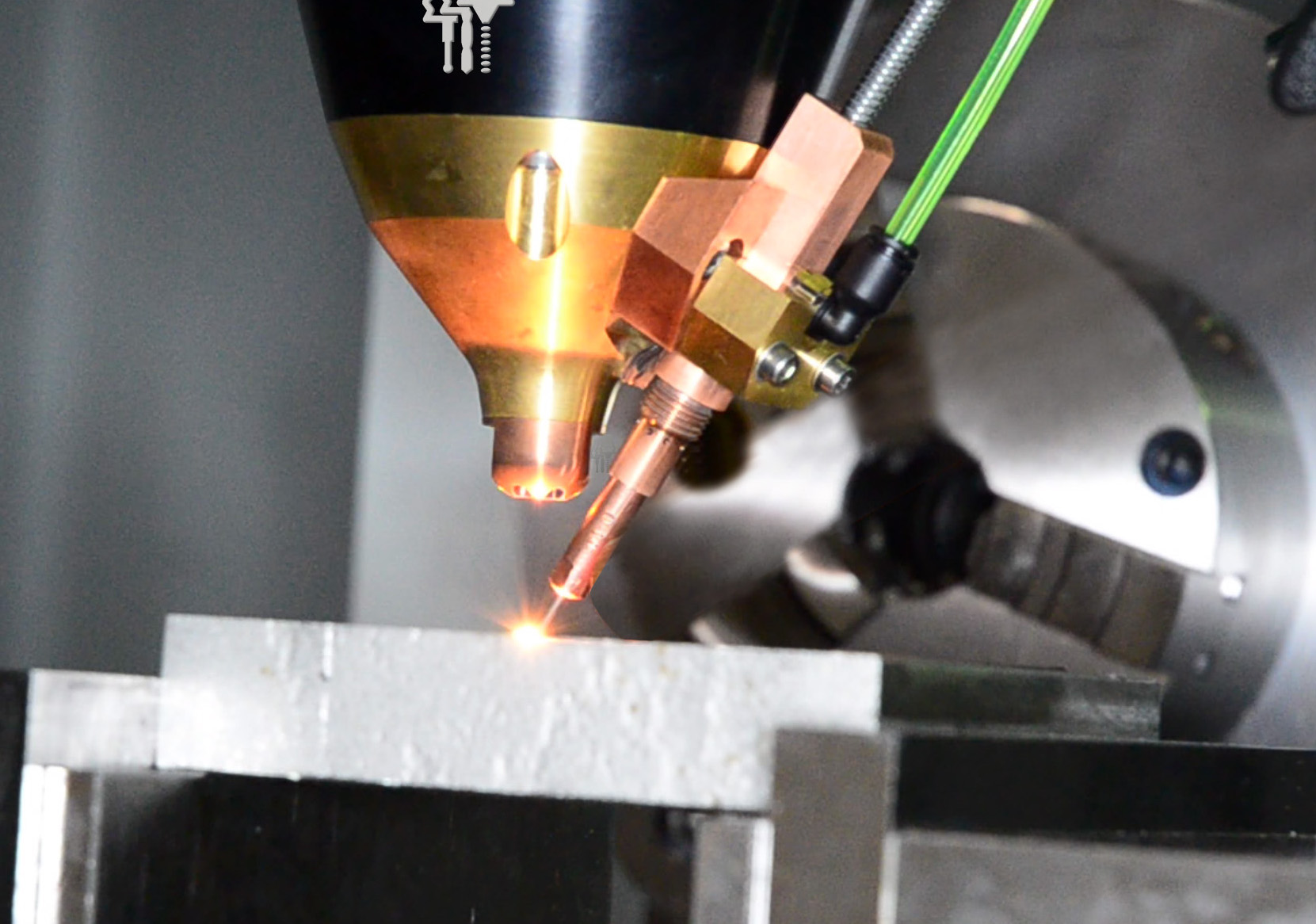

Founded in 2012, HMT specializes in combining 3D printing and milling through the marketing of its unique AMBIT DED head. Thanks to the device’s distinctive integrated design, users are able to fabricate parts with both additive and subtractive technologies, without needing to adjust the CNC machine’s structure.

Since developing the original AMBIT, the company has released a range of toolheads, inspection heads and laser scanners, with the aim of delivering optimal process versatility to its clients. The firm has also ventured into other areas of 3D printing, developing its new ‘AXIOM’ thermoplastic production method in May 2020.

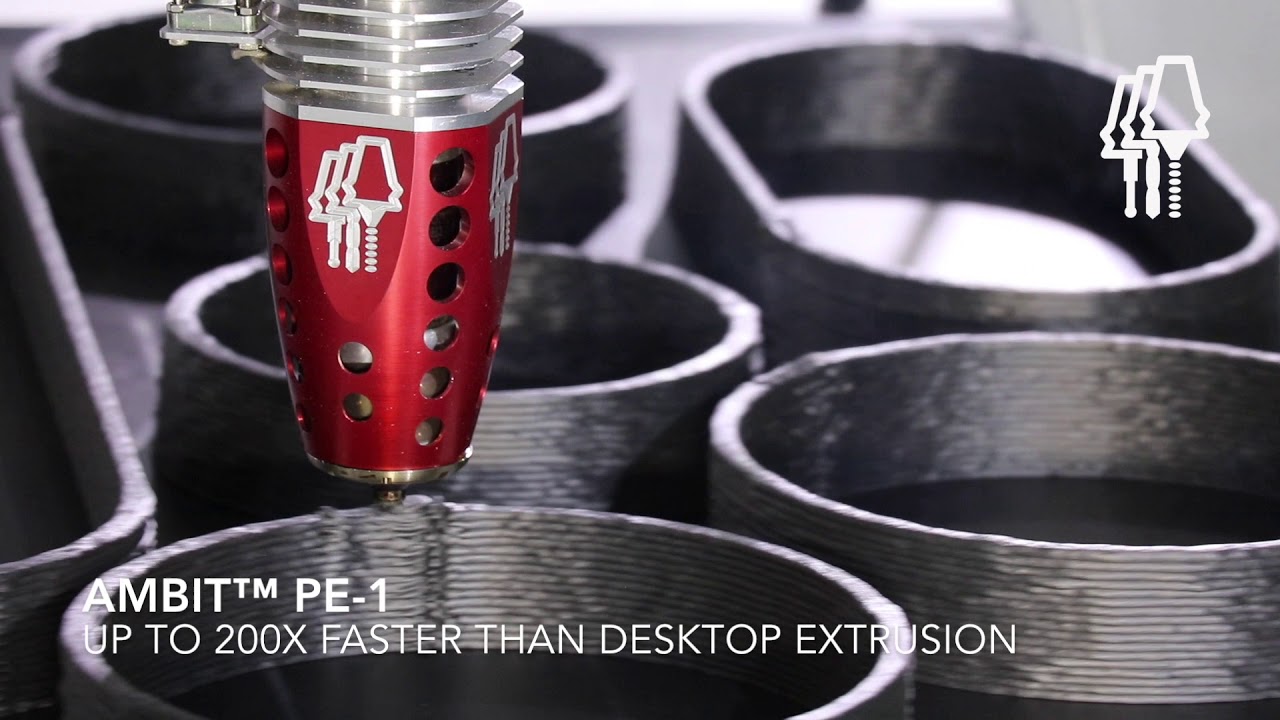

HMT’s hybrid process is designed to combine the speed and part quality benefits associated with injection molding with additive manufacturing to find a new “middle ground.” The company discovered its new approach when it attached its AMBIT XTRUDE PE-1 printhead to a CNC machine while producing PPE last year.

Many of the resulting parts were said to have an improved surface finish akin to those produced using injected molding. Although the XTRUDE PE-1 itself wasn’t new, and had already been attached to various robotic platforms, the new method at least reflected the firm’s commitment to continually refining its technologies.

Innovate UK and additive invention

Innovate UK was set-up by the British government to boost the development of advanced technologies, and it has often provided funding to 3D printing-based projects.

Meta Additive received a £1.2 million grant from Innovate UK in December last year, to further develop its novel proprietary binder jetting technology. The process reportedly achieves high part densities and low shrinkage rates, potentially making it well-suited to either aerospace or medical 3D printing applications.

Similarly, the University of Cambridge spin-out Blue Tap has been awarded Innovate UK funding to support the technical development of its 3D printed water purification technology. The firm’s additive chlorine doser is designed to be fitted into piped water systems in developing countries.

In the past, Innovate UK has also set up project calls, and in March 2019 the accelerator opened a £2 million funding competition to help further research in photonics technologies. Part of the R&D grant was reserved for the advancement of the laser machining, 3D printing, photonics curing or LiDAR processes.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows HMT’s AMBIT MULTI LMD-W head in action. Photo via HMT.