Engineering software developer CoreTechnologie has developed a new nesting function within its 4D_Additive print preparation program based upon artificial intelligence (AI) algorithms.

The AI ensures an even arrangement of parts in the build space during nesting via automated intelligent behavior and machine learning. Through this, the technology enables complex nesting tasks to be independently processed and simulates programmable decision-making structures.

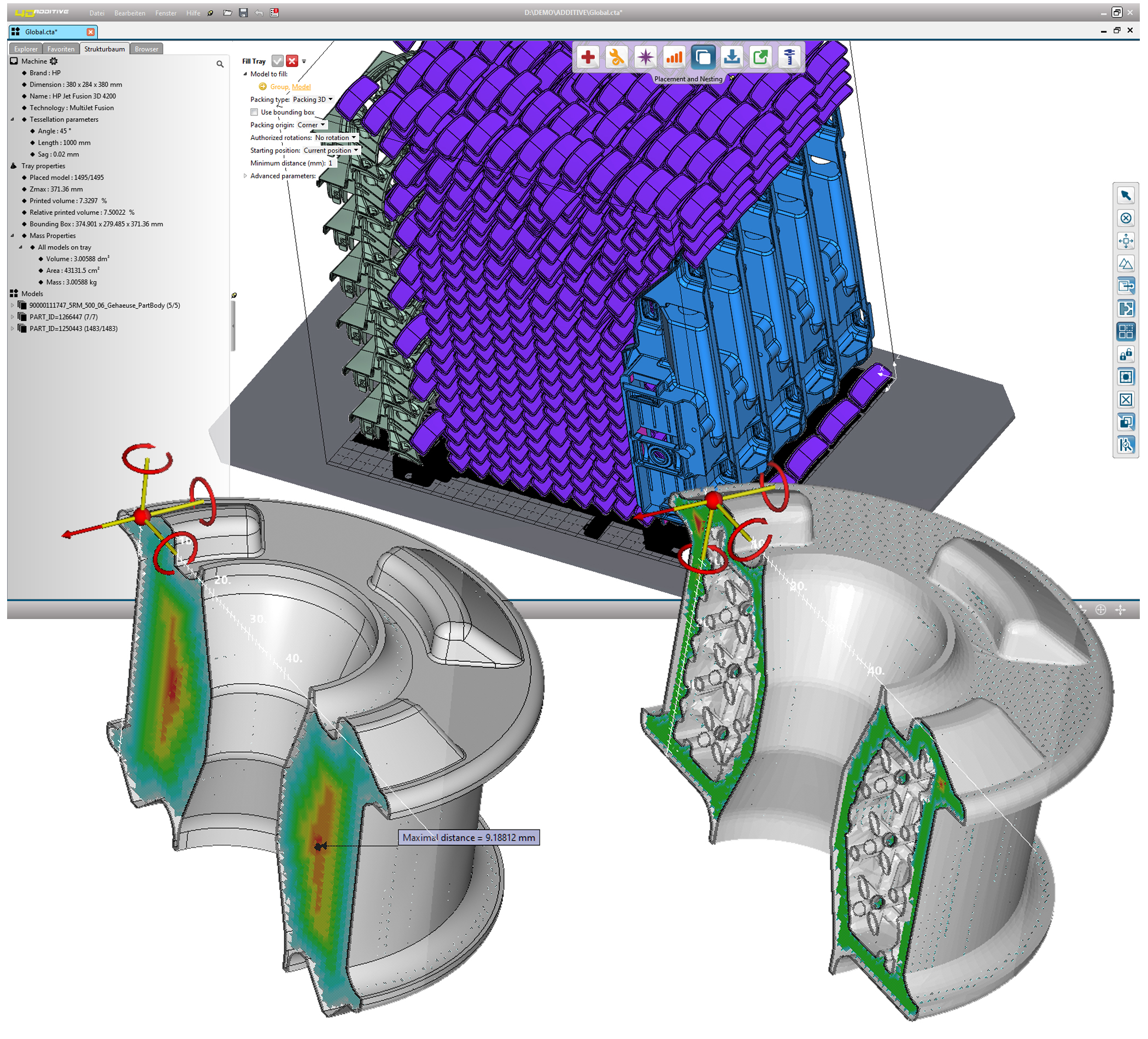

CoreTechnologie’s 4D_Additive software

The 4D_Additive software is built on a boundary representation (B-rep) file foundation which, when compared to the more widely used STL format, represents solids more precisely with a set of flowing surface elements. B-rep allows for highly accurate model repairs while enabling a set of modeling functions that aid in the 3D printing process. Users can upload 3D models from common CAD file formats and prepare them for printing using the 4D_Additive software.

In September, CoreTechnologie added the ISO-recognized STEP (Standard for the Exchange of Product model data) file format to its 4D_Additive software, which facilitates CAD file interchangeability between unrelated CAD systems. Last month, the company released another update for the software which allowed users to quickly and easily create latticed parts.

4D_Additive has CAD data interfaces for all B-Rep native and standard formates in addition to common 3D printing formats such as STL and 3mf.

Optimized component nesting

The new nesting module integrated into the 4D_Additive software is built upon a “pack and optimize” strategy. This ensures maximum filling of the installation space and evenly distributes the material to be printed, in turn facilitating constant slice surfaces.

Using AI technology, the program is designed to imitate the behavior of an experienced user by automatically filling empty areas in the packaging space after pre-positioning. As a result, build spaces are filled evenly and heat nests avoided.

In addition to the intelligent nesting function, CoreTechnologie has made further functions available to optimize heat distribution in components throughout the printing process. The software analyzes so-called “massive zones” to identify problematic areas with large material volumes, and flags these up to the user. Using the program’s hollow and lattice functions, these zones can be hollowed out and reinforced with an internal support structure if necessary. Holes and lids can then be created automatically to enable the removal of powder from inside the hollowed parts.

3D print preparation

For those seeking to optimize the design of their 3D printed parts, there are multiple print preparation software offerings available. In addition to 4D_Additive, CoreTechnologies’ software portfolio includes its 3D_Evolution, 3D_Analyzer, and 3D_Kernel_IO SDK formats.

Elsewhere, software developer VoxelDance launched its Additive 2.0 program earlier this year which featured several major upgrades, while AI specialist PrintSyst.ai unveiled a proprietary AI engine specifically designed for use with 3D printing within the aerospace, defense, and automotive sectors. Elsewhere, 3D printing startup TOffeeAM raised $1 million to fund the development of its award-winning topology optimization software.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Be sure to subscribe to the Another Dimension podcast on your chosen podcast player to make sure you never miss an episode.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the new 4D_Additive software version uses artificial intelligence for nesting. Image via CoreTechnologie.