Engineering software developer CoreTechnologie has added the STEP file format to the latest version of its 4D_Additive 3D printing data preparation software.

The ISO recognized ‘Standard for the Exchange of Product model data’ file type is designed to enable CAD file interchangeability between unrelated CAD systems, making the sharing of 3D models simpler. Now, with version 1.4 of the program, users are able to save their repaired and optimized CAD models as precise STEP data, increasing geometric accuracy and saving on memory usage.

A contender to STL

The 4D_Additive software is built on a B-rep, or boundary representation, file foundation. Compared to the more widely used (and more primitive) STL format, the B-rep method represents solids more precisely with a set of flowing surface elements, and enables file formats such as CATIA, NX, and CREO. Rather than a mesh of triangles, which can really only be an approximation at best, B-rep defines models by their exact limits – where solid ends and fluid begins.

While B-rep allows for highly accurate model repairs, it also enables a set of modelling functions that aid in the 3D printing process. Additionally, 3D files can be modified with offset surfaces and diameter changes at will, lending themselves to further processing with milling machines and Ensat bushings.

STEPping into 4D_Additive

Utilizing the strong B-rep foundation, the STEP format will give users a more precise model representation method. Additionally, CoreTechnologie claims that STEP files require lower storage space for the same geometries when compared to classical STL files. Large-format build platforms with tens or hundreds of parts can be consolidated down into compact file sizes, shortening lead times with resource efficiency.

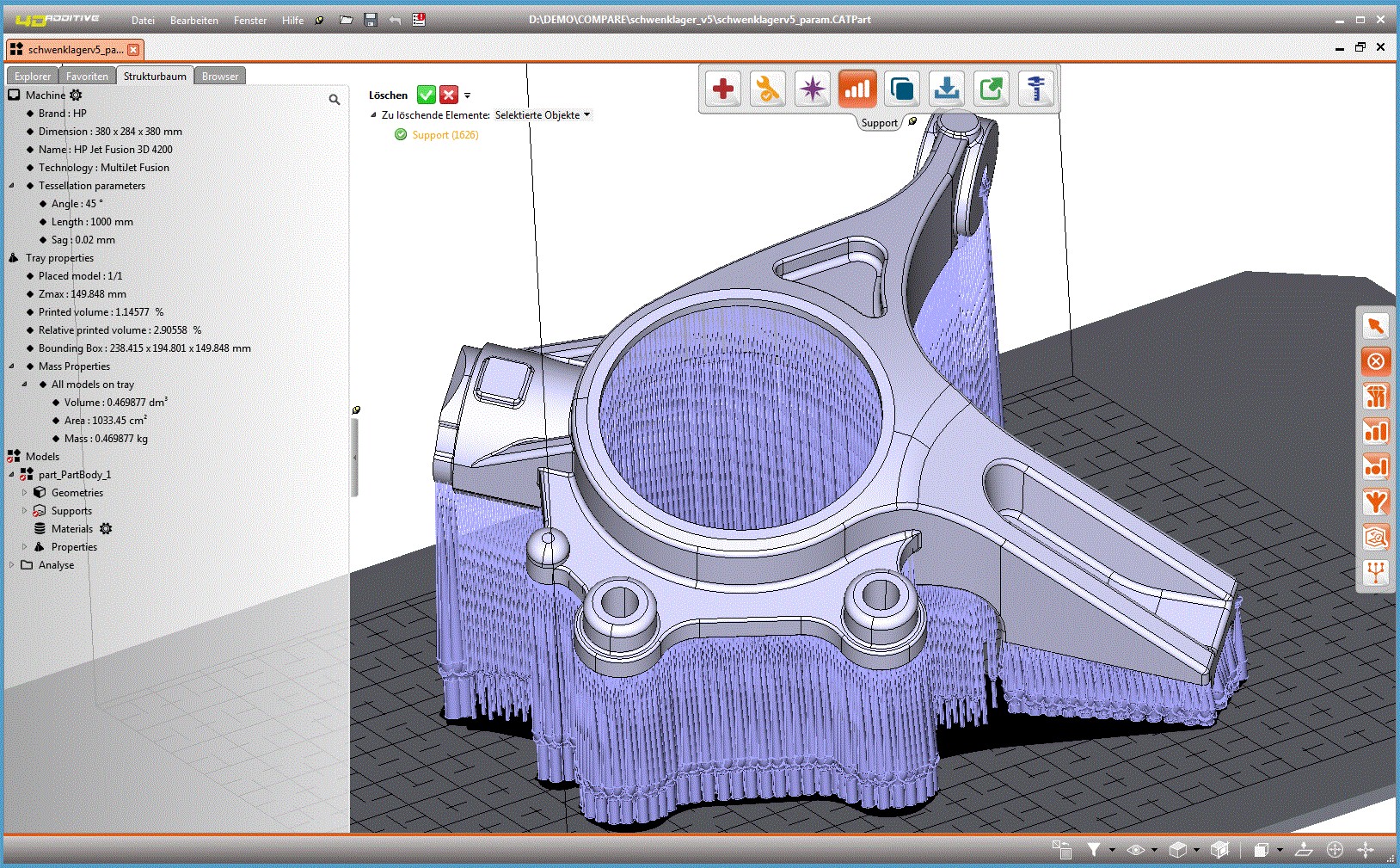

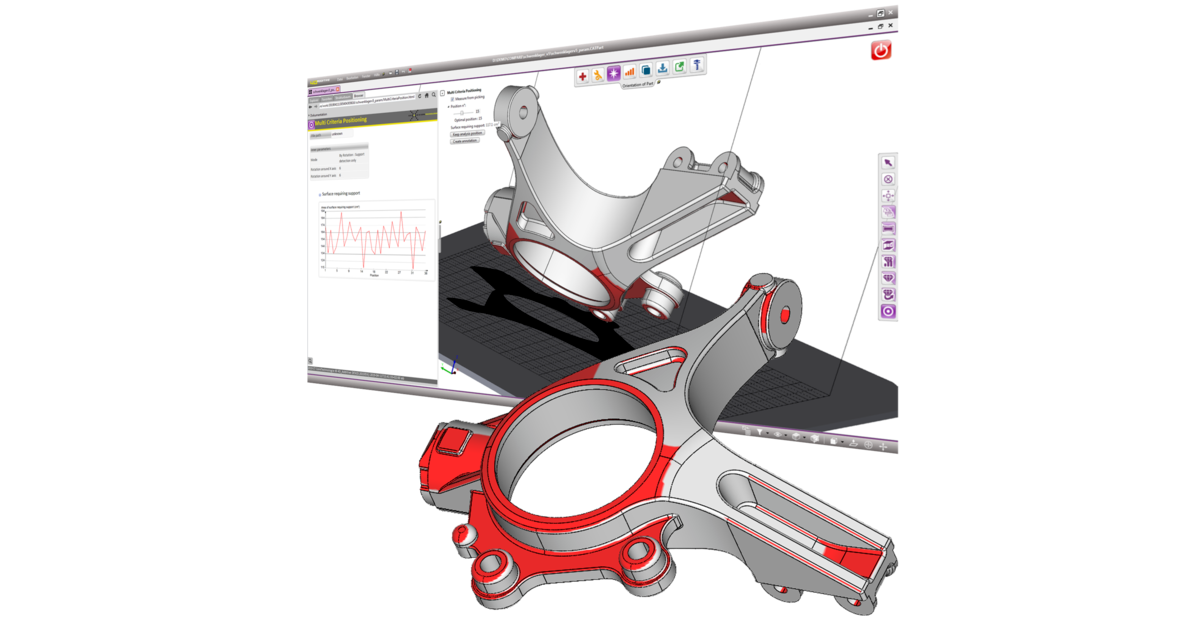

The software package currently features automated support generation, intelligent part alignment, and optimized model nesting for a variety of 3D printing technologies. An innovative texture module for surface refinement and part labelling functionality also give the program a quality-of-life boost. Furthermore, in-built analysis functions ensure collision-free build platforms and efficient heat distribution between 3D parts, streamlining the print preparation process. With the addition of STEP, users will be able to export fully supported models in the STEP format for further CAD processing or finite element analysis before printing.

Print preparation programs in additive manufacturing

There are three main stages to the 3D printing workflow: pre-processing, printing, and post-processing. The pre-processing stage, as integral as any, is facilitated by the plethora of print preparation programs currently on the market. Just last month, VoxelDance launched Additive 2.0 – the second iteration of its own 3D printing data preparation software. The program is compatible with a whole host of 3D printing technologies and features automatic support generation, precise STL file repairs, and intelligent 2D/3D model nesting in the build chamber.

Elsewhere, taking a more ‘artificial’ approach, PrintSyst.ai recently launched its new proprietary AI engine specifically for 3D printing – the 3DP AI-Perfecter. The pre-processing evaluation tool utilizes deep learning to predict a part’s probability of success, making suggestions for materials, print parameters, and geometries based on the intended application of the component. The software is intended to reduce labor costs and shorten the time to market.

The 4th annual 3D Printing Industry Awards are coming up in November 2020 and we need a trophy. To be in with a chance of winning a brand new Craftbot Flow IDEX XL 3D printer, enter the MyMiniFactory trophy design competition here. We’re happy to accept submissions until the 30th of September 2020.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows 4D_Additive print preparation software. Image via CoreTechnologie.