Software developer VoxelDance has launched VoxelDance Additive 2.0 – the second iteration of its 3D printing data preparation software. With six months of user feedback and ongoing refinement behind it, version 2.0 brings with it a number of major updates designed to make print preparation all the easier.

VoxelDance Additive 2.0 is compatible with a whole host of 3D printing technologies including SLA, DLP, SLS, and SLM. The software enables a comprehensive 3D printing data preparation workflow, with easy-to-use but powerful features. Beyond just automatic support generation, it is capable of precise STL file repairs and intelligent 2D/3D model nesting in the build chamber.

Improvements to the repair and nesting algorithms

The latest version of the software features an updated automatic model repair algorithm, which is used to ‘plug up’ holes and consolidate misaligned components of 3D models. The new algorithm was tested on 4000 models and returned an impressive repair success rate of 99%, with two new repair modes being made available. ‘Simple repair’ is faster but will not repair intersections, while ‘standard repair’ will fully repair the model at the cost of time and computational power.

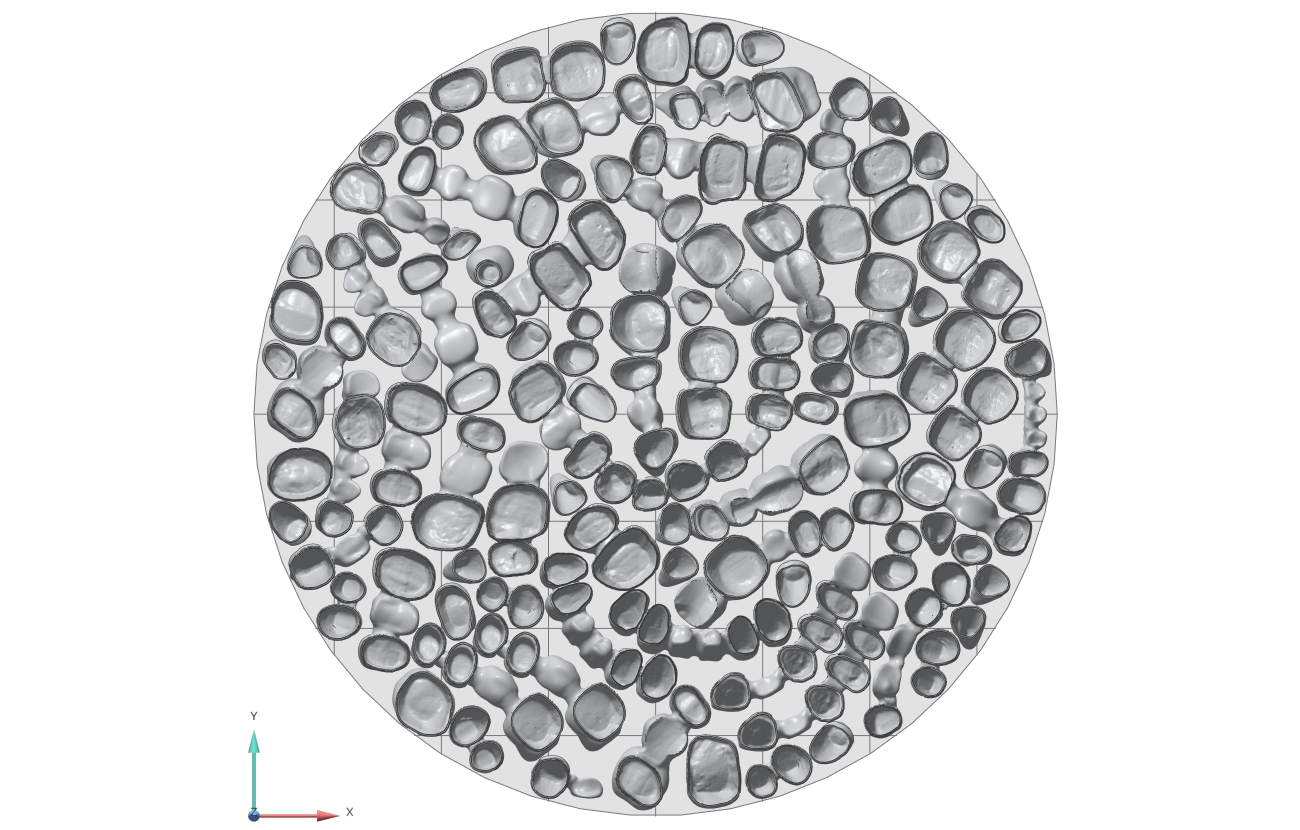

Additive 2.0 also provides a new and improved 2D nesting algorithm, which aims to optimize the placement of models on the build platform for maximum throughput. The placement density has been increased with tighter tolerances and multiple placement strategies have been made available. Users now have the option to arrange models according to part height or starting from a specific area of the build plate.

Advanced DLP and SLM supports

VoxelDance has also revamped the support functions for DLP and SLM printed parts. The latest DLP smart support module features a new cross-connect support geometry, which is stronger and more reliable than the common bar support. The software also now connects border supports with one another, allowing the user to customize certain parameters of the crossbar connections such as starting height and connection angle.

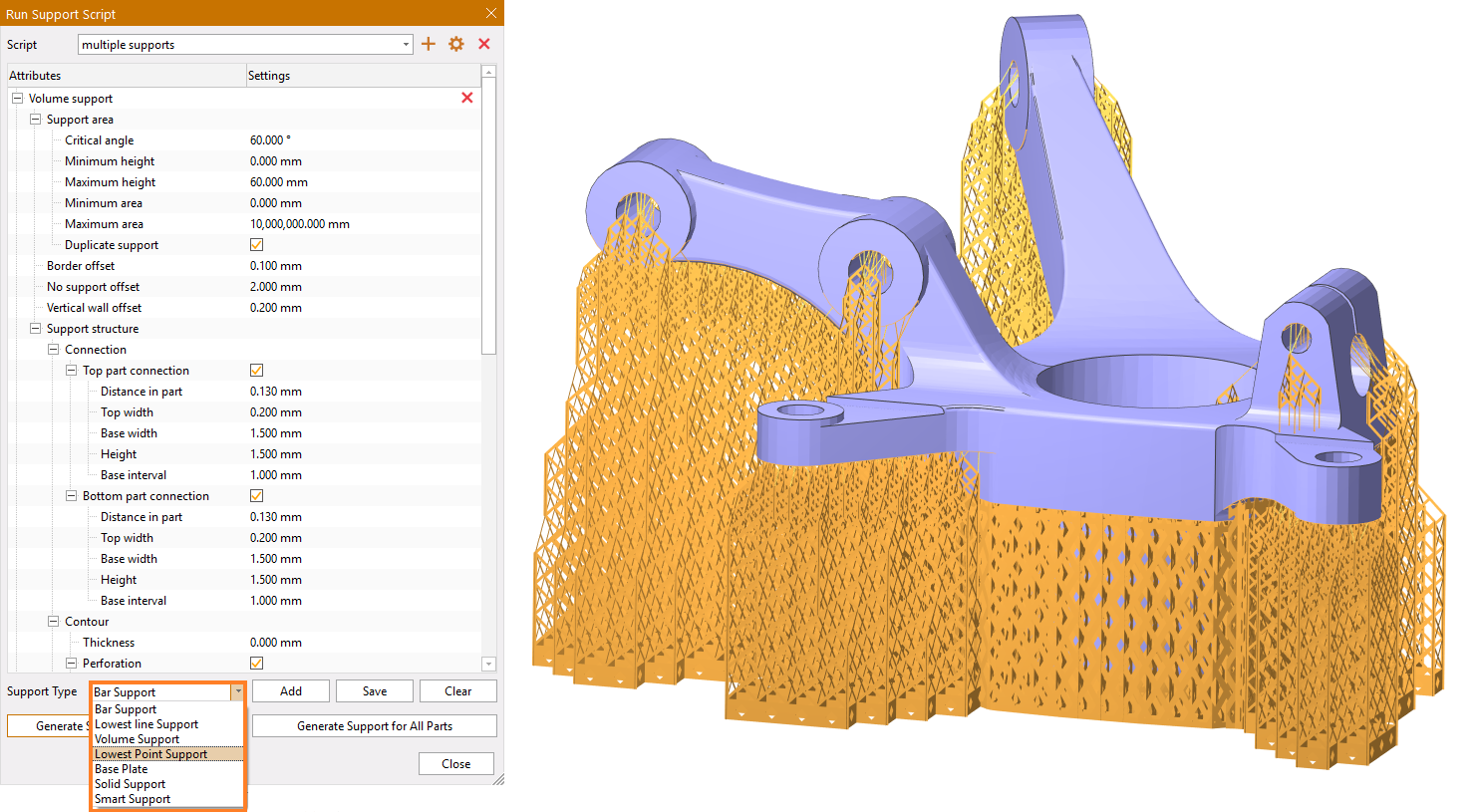

The SLM support module has been upgraded to include additional automated support types such as the volume support, lowest line support, solid support, and smart support. The angles, heights, and areas of individual supports can be modified by the user to fine-tune the build and meet specific needs. Naturally, users are also able to manually place supports as and when needed, with customization options for the type and dimensions.

Christopher König, CTO and co-founder of 3D printing service provider Dreigeist, states: “VoxelDance has enabled us to quickly go through several design iterations – maintaining focus on the product development. Instead of having to add support structures to each individual design, we used a Smart Support Template turning the printing part of the development into a click-and-print workflow. Thus, the designer had more time to work on the perfect fit design instead of spending hours on print preparation.”

To tie it all together, Additive 2.0’s general user experience has also received some quality-of-life updates. The software features new zoom views and a QR code activation function that activates the software while bypassing any activation errors. Readers interested in VoxelDance Additive 2.0 can apply for a one-month free trial here.

The 4th annual 3D Printing Industry Awards are coming up in November 2020 and we need a trophy. To be in with a chance of winning a brand new Craftbot Flow IDEX XL 3D printer, enter the MyMiniFactory trophy design competition here. We’re happy to accept submissions until the 30th of September 2020.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the SLM support module with new support types and parameters. Image via VoxelDance.