AI specialist PrintSyst.ai has launched its new proprietary AI engine specifically for 3D printing – the 3DP AI-Perfecter.

The pre-printing evaluation tool is designed to enable professionals working in aerospace, defense, and automotive to increase their print success rates with ever-improving ML algorithms. The company believes its product will reduce labor costs in the long run, while shortening the time-to-market for its clients.

Noam Taube, VP of Marketing & Sales at PrintSyst, states: “We are thrilled by the opportunity to assist our customers in overcoming a significant pain point in the 3D Printing process and thus enabling them to become more efficient and ultimately further grow their business. We believe that 3D printers that operate in highly regulated, industrial markets would gain the most value from using our 3DP AI-Perfecter, and are looking forward to closely collaborating with them.”

Pre-processing in additive manufacturing

Pre-processing involves analyzing a part before any actual printing commences, in the hopes of identifying and correcting any performance or printability concerns. For heavyweight engineering components, pre-processing requires a team of dedicated engineers closely inspecting the material choices, process parameters, and general regulatory compliance of the part. It’s one of the more time-inefficient stages of the additive manufacturing workflow and can be quite costly.

Deep learning algorithms

The collision of two industry 4.0 technologies is always exciting. The Perfecter, in particular, utilizes deep learning with the ultimate goal of cutting the cost of the pre-processing stage. By first predicting a part’s probability of success, it makes suggestions for materials, print parameters, and geometries based on the intended application of the component. According to PrintSyst, this can shave days off what would otherwise be a tedious period of trial and error.

Itamar Yona, CEO of PrintSyst, adds: “The AI enables instant, automatic and accurate pre-printing part analysis that could save more than 99% of the preparation time and cost. It is a scalable tool and using it is extremely user friendly and simple.”

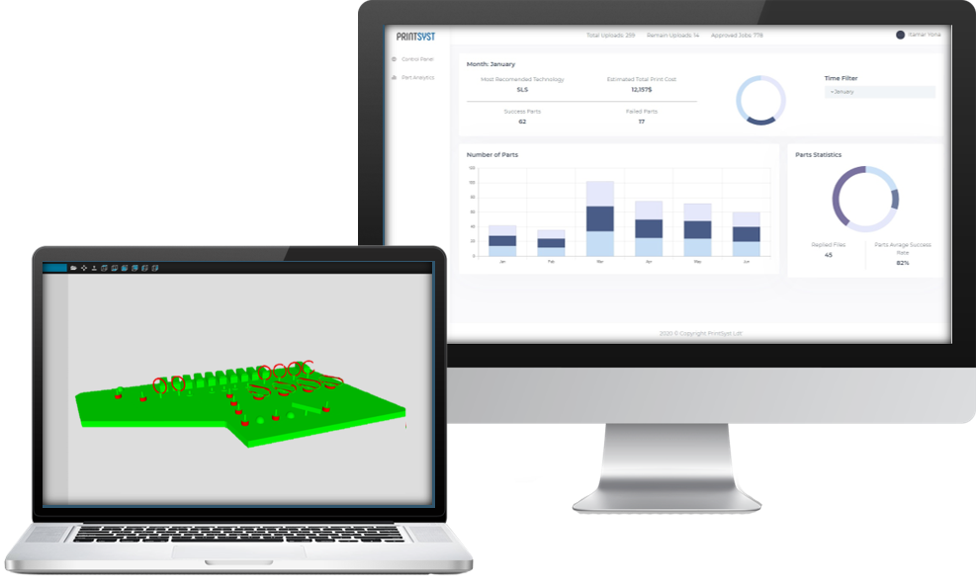

The Perfecter also features a “clever dashboard” that can be used to monitor the actual impact of the suggestions on the print process. It is fully customizable and intends to optimize the customer’s operations.

This is not AI’s first stint in the 3D printing industry, as companies and research institutions alike have previously employed the technology for additive manufacturing purposes. Imperial College London recently raised $1M in seed funding off the back of its TOffeeAM topology optimization software. It uses state-of-the-art maths models combined with artificial intelligence to design and improve aircraft and automotive components.

Elsewhere, in Italy, medical implant manufacturer REJOINT is introducing mass customization and therapy personalization through the use of artificial intelligence. The company plans to use GE Additive EBM technology to manufacture personalized ‘smart’ knee replacements.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows PrintSyst’s 3DP AI-Perfecter. Image via PrintSyst.