TOffeeAM, a 3D printing topology optimisation software spinout from Imperial College London (ICL), has raised $1m in seed funding.

The investment round was led by venture capitalist firm IQ Capital and supported by the Royal Academy of Engineering and ICL’s Techcelerate program. Ed Stacey, Managing Partner of IQ Capital, commented: “With the intelligent software the team has developed, and the strong deep tech expertise of the team, the sky’s the limit in terms of TOffeeAM’s capabilities, and I’m looking forward to seeing the role they can play in the field of smart industrial production.”

Using the additional funding, the company plans to hire engineers and additional staff, expand upon its existing engineering capabilities and to further develop its customer base. Despite the fact the company has only been trading for a year, TOffeeAM already boasts clients such as GE Aviation, Baker Hughes and a Formula 1 motor racing team, and the added investment is aimed at driving further growth.

“This funding will give TOffeeAM the opportunity to continue our success at speeding up 3D printing across all industries by up to 20 times faster, and to expand our team with expert engineers and other team members, and continue to scale the solution to serve our rapidly expanding customer base,” said Francesco Montomoli, CEO and founder of TOffeeAM.

“We are delighted to receive this funding from our investor partners – it’s a fantastic indication of their faith in the commercial applications of our technology.”

TOffeeAM’s 3D printing software package

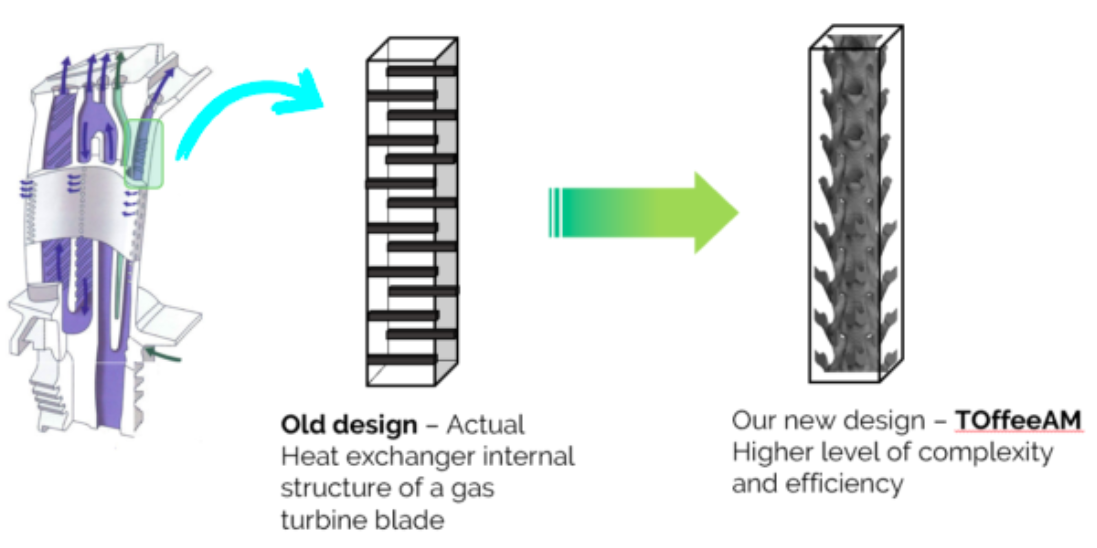

Founded in March 2019 by ICL graduate trio Francesco Montomoli, Marco Pietropaoli and Audrey Gaymann, the IP is based on four years of research at the university. TOffeeAM’s software package is designed to optimize the topology of 3D printed components to best suit their target application. The ICL team’s software also optimizes entire systems, by reducing the overall number of component parts and increasing the resilience of systems as a whole.

“Our software uses state-of-the-art maths models combined with artificial intelligence to design and improve components such as those used in aircraft and car engines,” explained Pietropaoli. “We can create more efficient, more resilient and more robust components. They might be lighter, or they might help reduce fuel consumption. The advantage of designing components in this way is what we call ‘robust optimisation,’ which means they can cope with errors in design data or in manufacture.”

As a result, the company claims that its software creates robust parts 20 times faster and 40 percent more efficient than those 3D printed using conventional methods. Moreover, the company’s package has been utilized within smart industrial production, producing coolant systems for gas turbines that exceed the performance of current heat exchangers. This makes the software well suited to applications within the aeronautics and automotive industries, where part design still relies on limited human intuition.

The topology optimization software was initially developed as part of ICL’s Techcelerate program, which supports the university’s graduates in setting up new businesses, and allows them to test their ideas on the market. “Techcelerate was the best programme I experienced at Imperial because it doesn’t try to do too much,” added Pietropaoli. “For three months you can focus just on customer discovery.”

Since completing the program in 2018, the start-up has gone from strength to strength, licensing its software and gaining custom from industry stalwarts such as GE Additive. Its optimization tools have even received industry recognition and awards including the Enterprise Fellowship, from the Royal Academy of Engineering, a Techcelerate prize, the Amazon AWS Programmable 2018 and the Amelia Earhart Fellowship.

“TOffeeAM’s success to date is a source of great pride for Imperial, and we’re pleased to see the company reach this latest milestone,” said Brijesh Roy, Seed Investment Manager at Imperial College London. “The combination of technical innovation and customer understanding TOffeeAM has achieved since inception, offers an outstanding example of the benefits of translating university research to industry.”

Nonetheless, for the company to keep expanding, it needed additional investment to grow its team of engineers and meet an increasing customer demand. Now with the investment from IQ Capital, the tech start-up will continue to develop new applications for its optimization software, with the aim of gaining new clients in the process. “We are at the beginning of an exciting journey, and this funding will help drive our growth and the wider use of this transformative technology across a variety of industries,” concluded Montomoli .

Start-up software in additive manufacturing

Optimization software is increasingly being adopted by 3D printing businesses seeking to design the most efficient possible components and this has led a number of software companies to develop their own workflow solutions.

UK-based software developer Additive Flow for instance, has introduced its FormFlow 3D printing software, aiming to solve the digital challenges currently present within the additive manufacturing workflow. The program is designed to be adaptable to a range of materials and processes, facilitating efficient and sustainable design for a wide variety of applications.

3D printing service provider Materialise has also released an updated version of its data and build preparation software, Magics 23. The update introduced new integrated automation features for metal 3D printing, including simulation and automatic support generation.

Elsewhere, New York-based 3D printing software developers LINK3D has launched a new production planning and scheduling solution for its additive manufacturing workflow software. The Production Planning System (PPS) is designed to aid users in maximizing machine utilization, track and trace yield, and capacity management.

You can now nominate for the 2020 3D Printing Industry Awards. Cast your vote to help decide this year’s winners.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a group of researchers using TOffeeAM’s optimization software. Image via ToffeeAM.