Metal additive manufacturer Sintavia has announced a collaboration with Siemens Digital Industries Software, the automation and digitalization software branch of industrial manufacturing company Siemens, for the development of an end-to-end additive manufacturing software solution as part of Siemen’s Xcelerator portfolio.

The three-year agreement will see Sintavia provide Siemens with testing and technical feedback on pre-released software. In exchange, the company will become a preferred additive manufacturing partner of Siemens, gaining access to the software in advance of the market as well as technical support for its implementation.

“We’re excited to be collaborating with Siemens to help make industrialized additive manufacturing a reality,” said Brian Neff, Sintavia CEO. “The end-to-end solution that Siemens has been developing is absolutely essential to making additive a viable manufacturing process.”

Siemens’ AM solution

According to Neff, the value of Siemens’ solution goes beyond digitally connecting phases of the additive manufacturing process. In order for Sintavia to achieve optimal efficiency, there is a need for software to codify the company’s processes, and not just connect them in a digital thread but to automate them.

Aaron Frankel, vice president of the AM program for Siemens Digital Industries Software, said: “The collaboration with Sintavia is vital to our efforts to develop an automated end-to-end solution that spans the entire AM lifecycle – from designing an optimized part, preparing it 3D printing and simulating its build, to planning serial production, executing on the shop floor, and delivering a qualified part.”

Through the partnership, Sintavia will provide technical feedback to Siemens which will allow additive manufacturing know-how to be built into its digital twin, enabling the system to become the expert, as opposed to the user.

“This is a critical step to making additive more widely embraced for volume production,” continued Frankel. “Unlike traditional manufacturing, additive is a process where we don’t have decades of established knowledge that is readily communicated, whether in software or through technical education. Companies can’t afford to make everyone in the AM process an expert; they need the software to automate some tasks, work in the background, and make additive more of a push-button process.”

Other elements of the agreement

As part of the collaboration, the two firms will work together on joint sales and marketing activities and are planning to organize events at Sintavia’s facility to showcase Siemens’ solution in an industrialized additive production environment.

Sustainability will also be a key area for the companies’ marketing collaboration. In November last year, Sintavia co-founded the Additive Manufacturer Green Trade Association (AMGTA), a global nonprofit organization open to any additive manufacturer or industry stakeholder that meets certain criteria in regards to production sustainability. Siemens joined AMGTA this year.

“Siemens has a strong commitment to sustainability – it is a key part of the Siemens 2020+ vision,” said Frankel. “Siemens’ additive manufacturing software contributes to greener additive manufacturing production not just by streamlining designs and reducing material usage, but also by leveraging simulation to help enable first-time-right 3D printing and optimize AM factory efficiency to eliminate waste.”

At the tail end of last year, Siemens undertook the process of validating 3D printed burners key to a fossil-free fuel initiative in Sweden.

Siemens Digital Industries Software in AM

In November last year, Siemens committed to the acquisition of virtual testing software developer MultiMechanics, and also introduced Additive Manufacturing Path Optimizer (AM Path Optimizer) technology to its NX software offering.

Shortly after, the company signed an OEM partnership with Identify3D, a San Francisco-headquartered software company, to enable the integration of Identify3D’s security suite within Siemens’ software solutions. The aim was to support customers in creating automated, end-to-end, secure, and controllable manufacturing data distribution across multiple control systems and production equipment.

The 4th annual 3D Printing Industry Awards are coming up in November 2020 and we need a trophy. To be in with a chance of winning a brand new Craftbot Flow IDEX XL 3D printer, enter the MyMiniFactory trophy design competition here. We’re happy to accept submissions until the 30th of September 2020.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

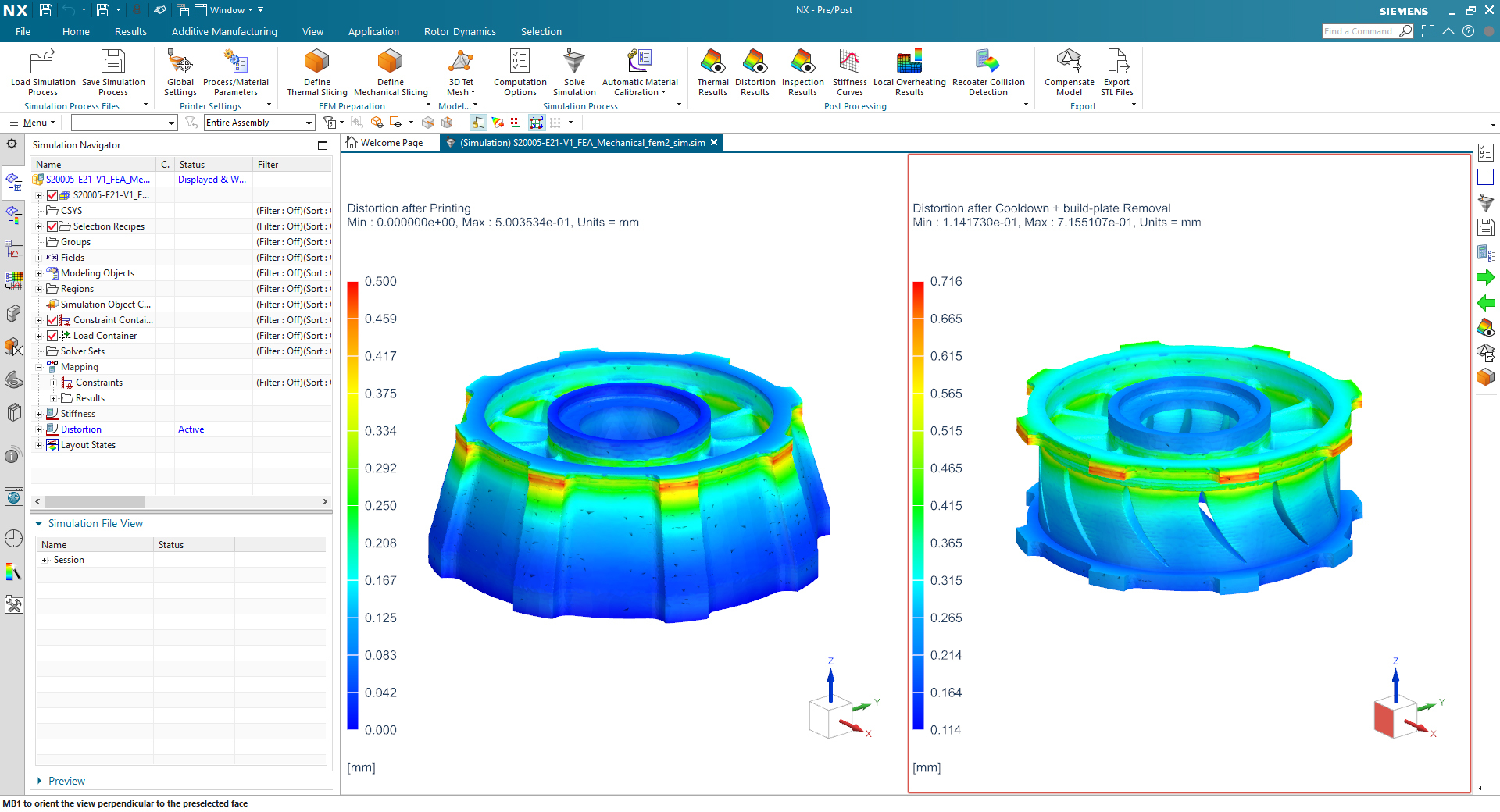

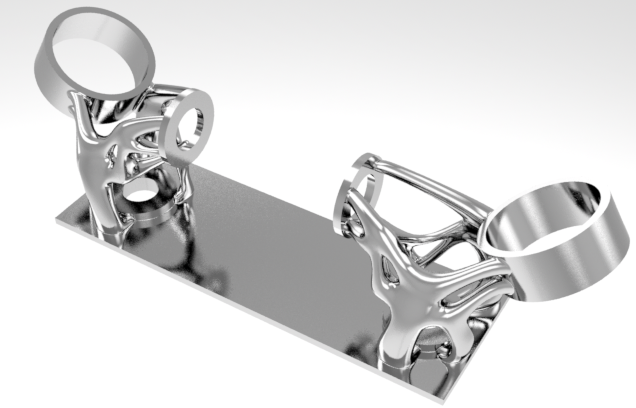

Featured image shows a simulation designed by Sintavia of an aerospace nozzle guide vane ring, both with and without supports, using Siemens Xcelerator simulation software. Image via Business Wire/Sintavia.