Colorado software company, Frustum has announced it will provide a topology optimization generator for Siemens NX software. Global manufacturing company, Siemens will add Frustum’s technology into their “end-to-end additive manufacturing solution.” Siemens NX is a platform that is used in the designing, analyzing and manufacturing processes for 3D printing. NX has roots in one of the world’s first end user CAM products.

Siemens is currently advancing their 3D software solutions and the use of industrial 3D printing. This integration of topology optimization software gives further insight into Siemens’ view of the future of industrial 3D printing and the role generative design will play.

Generate platform

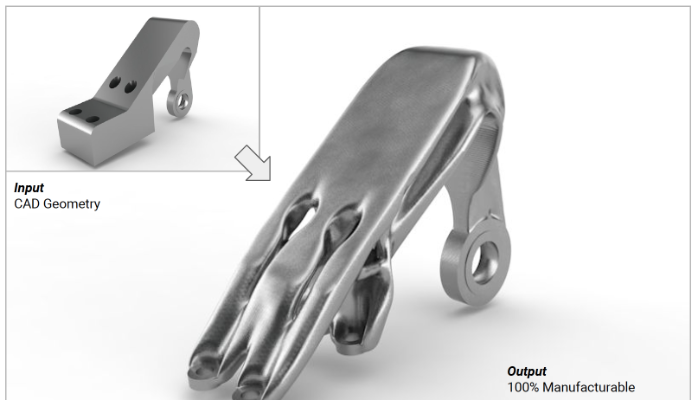

Frustum is well-known for their Generate Platform which automatically generates design options based upon weight, material, function and costs.

According to Frustum the software, “streamlines a product’s shape by automating weight and material reduction while still retaining structural integrity.” By integrating Frustum’s technology the software now, “enables the creation of an optimized design that can then be quickly refined and made ready for additive manufacturing, using Convergent Modeling.”

Siemens is working with a number of 3D software companies, including Belgian company Materialise. The approach taken by the German manufacturing leader is interesting when compared to the acquisitive strategy and consolidation of OEMs by GE Additive. Siemens PLM Software, of which NX is a flagship product, has sold over 15 million licences and has 140,000 customers worldwide. Integrating innovative 3D design software tools from third parties into an already widely used product is likely to yield substantial rewards, at least this is what Siemens will be hoping for.

Siemens has also partnered with industrial 3D printing OEMs to expand the use of the technology in manufacturing. As we reported recently, German metal 3D printing company Trumpf announced integration of Siemens NX software.

On the Frustum integration Bob Haubrock, senior vice president of Product Engineering Software for Siemens PLM Software said,

Siemens is excited to offer our NX customers this truly innovative topology optimization solution from our partner Frustum. Frustum’s unique technology, now fully integrated with NX and its unique Convergent Modeling technology, fits with Siemens’ approach and vision to free industrial designers and engineers to create the next generation of parts and products that closely match customer needs, reduce energy consumption, and drastically reduce the cost and time to market for these innovations.

Industrial 3D printing

As the largest manufacturing company in Europe, Siemens provides a good indicator of how 3D printing technologies may move further into production.

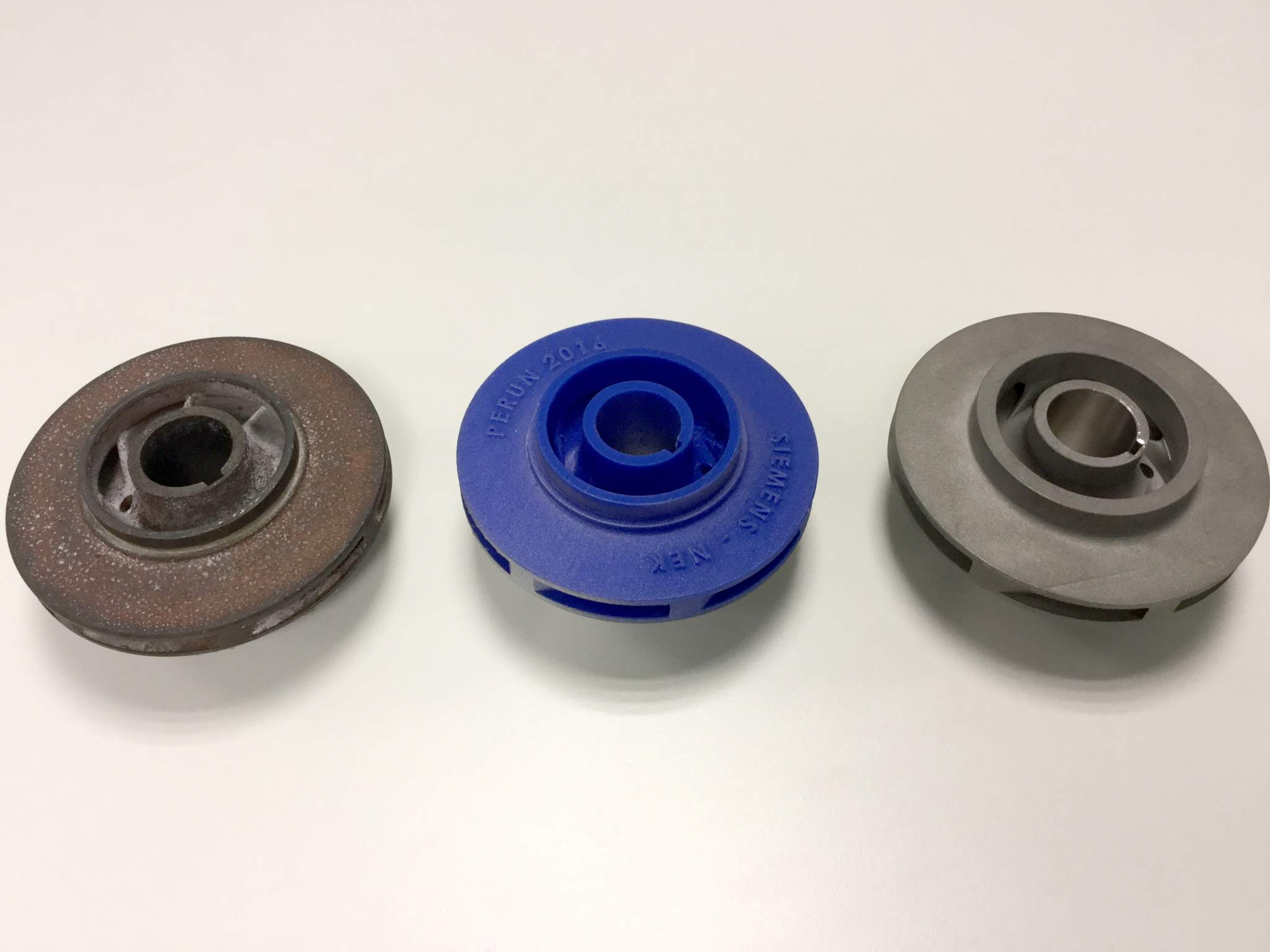

The German company is encouraging the use of the technology with their software offerings and also by applying the technology directly. Recently, Siemens used 3D printing to manufacture a replacement impeller for a nuclear power plant in Slovenia.

Jesse Coors-Blankenship, founder and CEO of Frustum spoke about the integration,

As a partner with Siemens PLM Software, we are thrilled to be part of the Siemens NX solution. This is great recognition for the power of our technology and optimization framework, which removes some of the barriers associated with additive manufacturing. We are excited to enable Siemens NX customers to design fully optimized parts, ready for 3D printing, as well empower them to move beyond the boundaries of traditional CAD geometry.

Remember to cast your vote in the 3D Printing Industry Awards where Siemens are in the shortlists.

For the latest 3D printing news, sign up to our newsletter and follow us on our active twitter account.

Featured image shows Frustum Generate optimized part. Image via Frustum.