Engineering software developer CoreTechnologie has released an update for its 4D_Additive print preparation program, that allows users to quickly and easily create latticed parts.

The software’s revised lattice tool enables users to 3D print various types of internal and external grid structures, such as honeycomb, gyroid and star shapes amongst others. Utilizing this new functionality, users can now fabricate a range of complex, lightweight objects such as implants, that could have potential applications in the medical or construction industries.

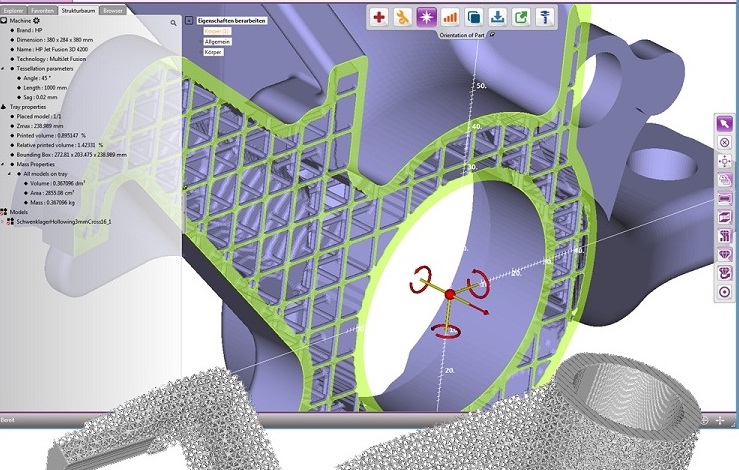

CoreTechnologie’s 4D_Additive software

Founded in 1998, CoreTechnologie is a Franco-German firm that develops a range of CAD data conversion software programs, with the aim of helping users to streamline their part design processes. At present, the company’s portfolio includes the 3D_Evolution, 3D_Analyzer and 3D_Kernel_IO SDK formats, as well as its 4D_Additive design suite.

CoreTechnologie’s 4D_Additive software enables users to upload 3D models from common CAD file formats such as STLs, and prepare them using its B-Rep (or boundary representation) file foundation. While STL files are often triangulated and distorted during the reading process, the B-Rep kernel is more precise, and enables clients to check, repair and handle the original data.

The firm’s advanced design software also features checking and healing functions, that analyze a user’s model, and eliminates gaps, overlaps and other types of errors. Even significant issues that are not correctable automatically such as knife edges, can be rectified using the program’s clean-up function, which enables the creation of ultra-precise models.

Recently, the company updated its 4D_Additive program to include the STEP file format, giving users a more accurate model representation method, and reducing the amount of space by each file. If used alongside a large-format system to produce hundreds of parts, the software’s more compact file sizes could allow users to improve both lead times and material efficiency.

Latticed structures at the “touch of a button”

With the launch of its latest software update, CoreTechnologies has revised its lattice module to allow users to create structures with internal or external grids at the “touch of a button.” The 4D_Additive software works by analyzing a part to achieve the best possible level of heat distribution, and identify the most suitable areas for lattice structures to be formed.

CoreTechnologies says that its lattice module is easy to use, calculating the dimensions of the revised 3D model within seconds, and allowing users to fill part voids with a variety of grid shapes. Using advanced modelling programs such as 4D_Additive, it’s now also possible to adjust an object’s properties to grant it application-specific properties.

Part characteristics such as weight, strength, energy absorption and thermal behaviors can all be tweaked via the software. As a result, latticed objects could potentially be altered to take on additional functions that would normally be achieved using assemblies. Sponge-like structures, for instance, could be used within gas storage facilities or even as implants that bones can grow into.

3D printed gyroid-patterned structures in particular, hold significant potential in a broad range of industries, as they never cross in the same layer twice, and don’t require any support. The advantage of using CoreTechnologies’ software to build these parts, is that users can easily switch between cubic or triangular patterns, depending on the compressive strength needed.

Print preparation and 3D printing

CoreTechnologie is far from the only company that offers print preparation software, and an abundance of options exist for those attempting to optimize the design of their 3D printed parts.

Software developer VoxelDance, for instance, launched its Additive 2.0 program last month. The update brought a number of major upgrades to the platform, including new functions that were designed to make the print preparation process more productive.

Similarly, AI specialist PrintSyst.ai has launched a proprietary AI engine that’s been specifically designed for use with 3D printing. The firm’s “3DP AI-Perfecter” pre-printing evaluation tool, uses ML algorithms to help aerospace, defense and automotive users increase their print success rates.

Elsewhere, 3D printing start-up TOffeeAM has raised $1 million to fund the development of its topology optimization software. The company’s program, which combines maths modelling with advanced AI to optimize the design of automotive parts, also won its team an award in the 2020 formnext start-up challenge.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a latticed structure being designed on CoreTecnologie’s latest version of 4D_Additive. Photo via CoreTechnologie.