3D printer manufacturer Nexa3D has worked with software developer CASTOR to launch its new ‘Ximplify’ cost analysis tool for additive manufactured parts.

Introduced as part of Nexa’s growing ‘NexaX’ digital twin platform, Ximplify combines process and geometry algorithms with validated workflows, to identify parts that could be optimized via 3D printing. The “decision support portal” is capable of scanning any CAD file and providing users with a full part cost and return on investment analysis “within minutes.”

“We are excited to partner with CASTOR,” said Avi Reichental, Co-founder, Chairman and CEO of Nexa3D. “Ximplify will deliver cost advantages to companies seeking to simplify their supply chain, by quickly identifying opportunities to migrate tooled plastic parts to just-in-time, on-site additive polymer production.”

Nexa’s online product ecosystem

Founded in 2016 and headquartered in California, Nexa3D is best known as a manufacturer of polymer-based 3D printers. The firm introduced its proprietary Lubricant Sublayer Photo-curing (LSPc) and Quantum Laser Sintering (QLS) print engines a few years ago, and it has since focused on enhancing its material and software offerings to compliment them.

Working with the global chemical firm Henkel, Nexa recently developed a new ABS resin for SLA 3D printing, and a range of medical-grade polymers. The company has also invested in its industry 4.0 preparedness via a partnership with Siemens, in which it will provide process monitoring and optimization tools for Nexa’s QLS systems from 2021.

In addition to incorporating Siemens’ software into its machines, Nexa has released its own program under the NexaX Digital Twin Printing (DTP) brand. The company’s new online platform offers to “optimize the entire 3D printing process” using interplay algorithms that ensure consistent part performance, while minimizing material usage and waste.

Working with the experienced software provider CASTOR, Nexa has now added the Ximplify tool to its quickly-growing NexaX portfolio, reflecting a shift in its approach from process management, to part cost analysis.

Part cost analysis made Ximple

Nexa has released its automated web app with the aim of making it easier for designers and manufacturers to adopt 3D printing technologies on a broader scale. Ximplify, therefore, is designed to reduce the risk, lead-times and ultimately the costs of switching to additive manufacturing, by allowing users to assess the profitability of changing before they do so.

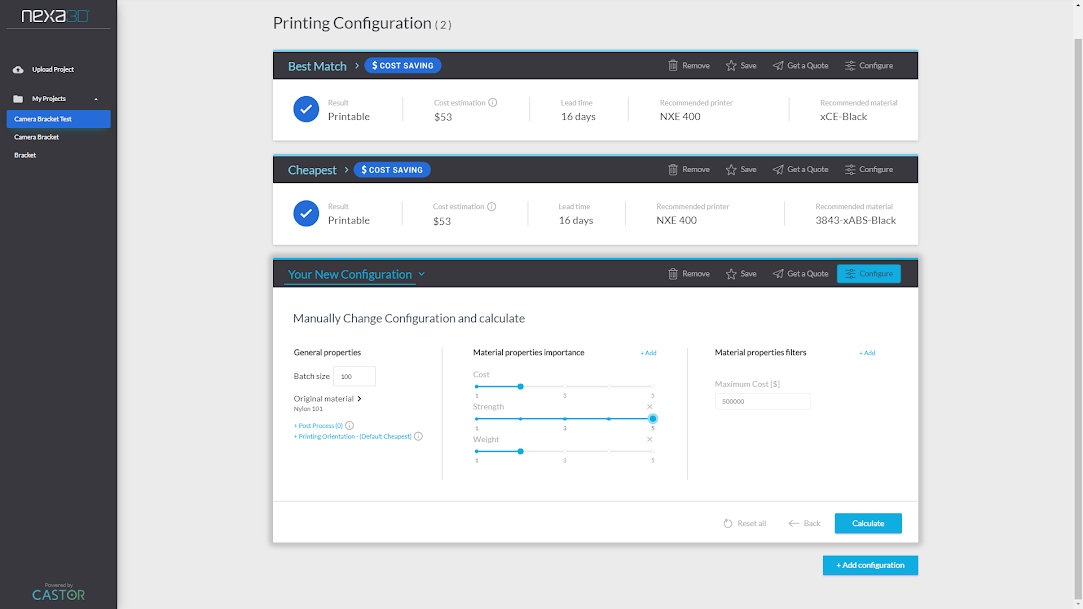

The online tool itself works using computational algorithms and end-to-end validated workflows to identify tooled plastic parts that would benefit from being 3D printed instead. Users simply need to upload a 3D model of a plastic object to the Ximplify website, and its CAD-agnostic system does the rest, scanning through a list of thousands of materials in minutes.

As well as recommending how the part could be optimized, Ximplify suggests the ideal process, system and polymer for the job. In addition, users receive an automatic report at the end of each session, that provides them with all the information needed to navigate the decision making and implementation process.

“We are thrilled to combine the power of our decision support software capabilities with Nexa3D’s digital twin software platform for the benefit of designers and engineers,” said Omer Blaier, Co-founder and CEO of CASTOR. “We see Nexa3D as a company with similar interests and values, and together we are taking another step towards digitizing the world’s supply chain sustainably.”

Marketing the benefits of 3D printing

As the cost benefits of adopting 3D printing for low-volume production become increasingly apparent, a number of firms have launched specialized software, to market these potential gains to clients.

In August 2020, 3Diligent opened a beta program of its ProdEX and Shopsight applications to all qualified users, after successfully concluding a pilot of the software. The online platforms connect engineers and buyers with manufacturers from around the world.

Technical solutions specialist Etteplan, offers AMOTool, a free online application that calculates the production costs of switching to 3D printing. The system only uses well-established metal 3D printing methods to provide users with a quick, risk-free valuation.

Elsewhere, metal 3D printer developer Optomec has launched a new Return On Investment (ROI) assessment tool. The cost calculator is built on the firm’s own experience in Maintenance and Repair Operations (MRO), enabling it to accurately assess the cost of 3D printing laser cladding and gas turbine components.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a screenshot from Nexa3D’s Formnext Connect booth. Image via Nexa3D.