Industrial manufacturing firm Siemens has partnered with SLA 3D printer manufacturer Nexa3D to fit its Quantum Laser Sintering (QLS) systems with a new suite of enhanced automation software.

The deal between the companies, will see Nexa 3D’s QLS line of printers shipped with Siemens’ Factory Automation and Edge computing technologies installed, starting with the QLS-350 3D printer in Q1 2021. According to both firms, the systems’ predictive maintenance, process monitoring and print optimization tools, will enable clients to operate their machines with a greater deal of automation than before.

Tim Bell, Head of Additive Manufacturing at Siemens Industry, said that the companies’ new collaboration would enable Nexa3D customers to get the most out of their 3D printers.

“We are very pleased to join forces with Nexa3D and together unleash the power and potential of our products to create more resilient and sustainable supply chains,” said Bell. “COVID-19 has underlined the incredibly rapid and flexible nature of our combined factory automation technologies and demonstrated how vulnerable the global manufacturing supply chain is to unexpected disruptions.”

“Working together with Nexa3D, we are bringing decades of proven Siemens factory automation experience and technology to additive manufacturing, to help customers mainstream mission critical production tools for future manufacturing strategies.”

Siemens’ 3D printing automation software

Siemens is a multinational manufacturer with interests in a range of sectors, and it has made considerable investments in the potential of 3D printing too. The company’s Digital Enterprise portfolio includes a number of additive hardware solutions, but it’s primarily focused on software-based services.

As part of its digital service offering, Siemens launched its Materials Solutions Smart Factory in December 2019, which comprised 19 industrial metal 3D printers. The facility enabled the digitization of spare parts for a range of companies, including those in the automotive, aerospace, and industrial sectors. Another key element of Siemens’ automation strategy is its Sinumerik ONE program, which it released last year.

Sinumerik ONE enables machine tool manufacturers to virtually map their entire development processes, or in other words, to create a digital twin. The system presents firms with the ability to simulate the programming, setup, and operation of machines, allowing them to assess the performance of their products before launch.

Siemens’ software solutions have already been adopted by a number of 3D printing companies, with the aim of driving greater automation within their business. For instance, in November 2019, the company installed its software onto EOS’ machines, providing its users with a fully-integrated workflow solution. Similarly, Siemens recently began working with metal additive manufacturer Sintavia, through which it hopes to develop an end-to-end 3D printing software solution.

Now, via a new partnership with Nexa3D, Siemens is integrating its Industrial Edge software into Nexa’s QLS range of SLA 3D printers, no doubt with further automation milestones in mind.

Nexa3D and Siemens’ industry 4.0 partnership

The stated aim of Siemens and Nexa3D’s collaboration is to prepare 3D printing for Industry 4.0, by providing clients with enhanced connectivity, digital twin sensing, and data acquisition capabilities. Industry 4.0 remains a common goal for many within additive manufacturing, as automated self-sustaining production lines could remove humans from the localized decision-making process altogether.

These enhanced productivity and cost benefits of industry 4.0 are well-established, and the companies are now pooling their resources, as they aim to bring further automation to their customers. Following the deal, Nexa 3D’s entire QLS line of polymer machines will feature Siemens’ Factory Automation and Edge computing technologies as standard from 2021.

Siemens’ Edge program is already commercially available and currently enables machine data to be directly and securely sent to a central system for administration, deployment, and updates. Leveraging the software solution, Nexa3D customers will now be able to utilize this processing data to optimize their manufacturing processes.

“We are very excited to partner with Siemens to jointly deliver the next generation of manufacturing capabilities to our customers.”

As a result of the agreement, Nexa3D will also be able to deliver 24/7 predictive maintenance, as well as process monitoring and print optimization services to clients. According to the company, this could allow its customers to effectively compress their design and manufacturing cycles, and scale their production on the factory floor.

Having worked with partners in the automotive, aerospace, medical and industrial sectors during the pandemic, Nexa3D views now as the ideal moment to bring further automation to the industry.

“We believe that this collaboration is essential given the strengths of the 3D printing industry as demonstrated throughout the COVID-19 pandemic,” said Kuba Graczyk, Head of Thermoplastic Additive Business at Nexa3D. “This is the right time to realize the combined potential that this partnership unlocks for the benefit of our expanding customer base.”

Nominations for the 2020 3D Printing Industry Awards are still open, let us know who is leading the industry now.

The fourth edition of the 3D Printing Industry Awards Trophy Design Competition is now underway. Enter your design for the chance to win a CraftBot Flow 3D printer.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

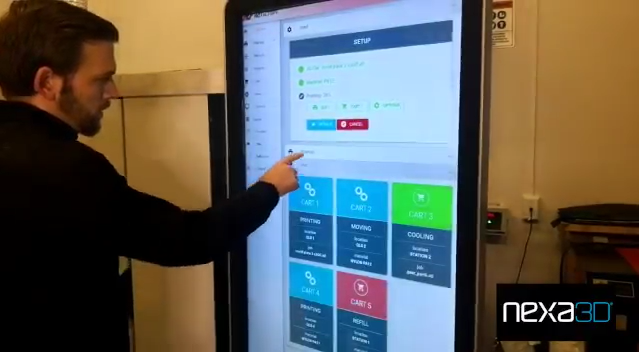

Featured image shows Nexa3D’s QLS 3D printing systems. Image via Nexa3D.