Additive manufacturing technology firm Teton Simulation has introduced a new Smart Slice update for desktop 3D printer manufacturer Ultimaker’s Essentials software platform.

Teton’s inaugural product offering allows users to assess the performance of objects before printing them, which reduces the number of product iterations required to create end-use parts. Leveraging the new plug-in, users could now be able to manufacture components more quickly, reliably, and cost-effectively than was previously possible using Ultimaker systems.

“Our Smart Slice technology was built from the ground up to give 3D printer operators near instant feedback on the viability of their project,” said Mike Kmetz, CEO of Teton Simulation Software. “There is simply no other solution in the industry that can provide lightning-fast, accurate feedback on the ‘as printed’ state of a part.”

“Our optimization feature takes the guesswork out of determining the right slicing parameters.”

Ultimaker’s Essentials platform

Ultimaker launched its Essentials platform in July 2020, with the aim of encouraging companies to incorporate 3D printing into their existing workflows. The paid subscription service helps businesses to overcome any barriers to entry, by providing access to Ultimaker’s recently launched eLearning platform.

According to the firm’s 2019 3D Printing Sentiment Index, 69 percent of industry professionals believe that a lack of knowledge is the greatest barrier to success. The Ultimaker 3D Printing Academy gives companies the resources they need to educate and train their employees. As a result, employers can now potentially roll-out Ultimaker’s range of software programs, without causing any disruption in productivity to their businesses.

The current Essentials package includes three online courses from the Ultimaker Academy, with difficulty levels ranging from novice to expert. In total, the Essentials bundle now comprises Cura Enterprise, Digital Factory, Marketplace, and a technical support team.

Given that updates and plugins such as Smart Slice are continuously being rolled out across the service, its user base could be set to benefit from further additions in the months ahead.

Smart Slice for Ultimaker Essentials

Teton Simulation’s new plug-in for Essentials is specifically targeted at reducing the uncertainty surrounding final part performance during Fused Filament Fabrication (FFF) 3D printing. At present, it’s very difficult to know how a fabricated end-use object will perform once it’s been fully-printed. According to Teton, this often necessitates up to 50 iterations of product trial and error, which leads to excessive print times and material wastage.

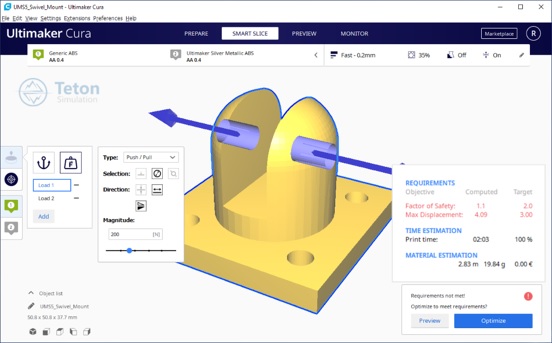

Smart Slice allows iterative changes to be made virtually within the software, which enables users to optimize their printer’s settings, and ultimately to reduce the costs behind their products. The cloud-based program is also seamlessly integrated into Ultimaker’s Cura platform via a plug-in, meaning that businesses can easily integrate it into their existing IT infrastructures.

“Teton’s Smart Slice brings engineering grade part simulation to Cura as an exclusive marketplace plug-in for Ultimaker Essentials users,” explained Paul Heijmans, Senior VP of Software at Ultimaker. “Using the integration options of our open and pluggable platform will make sure that parts still meet their engineering criteria, but need less material and therefore saving valuable time and costs.”

“We do all the work, so the user doesn’t have to. All of this capability is provided within the slicer making it very easy to use.”

The software update is also designed to be user-friendly, automatically optimizing parameters, and providing users with the optimal print settings for rapid production while using the least amount of material. What’s more, Smart Slice’s speed and efficiency reportedly make it well-suited to producing jigs and fixtures.

Sourcing replacement parts from traditional supply chains could take days or even weeks, leading many companies to begin 3D printing the components themselves. Using Teton’s new software, industrial manufacturers could now be able to accelerate tool replacement, and get production back up and running, as quickly as possible.

According to Heijmans, Ultimaker’s partnership with Teton shows that the company is continuing to expand its product offering for those customers that use its systems in a professional capacity. “The cooperation with Teton and the integration of their innovative solution are a prime example of how we will be continuously adding value for our professional customers,” concluded Heijmans.

Workflow software and optimizing 3D printing

An increasing number of additive manufacturing workflow programs have been released in recent years, with the aim of providing users with greater in-situ control over the 3D printing process.

Workflow software developer Authentise has partnered with Addiguru, a developer of real-time process monitoring systems, to progress its Authentise Manufacturing Execution System (AMES). Working together, the companies aim to integrate computer vision and AI-based in-situ monitoring functionality into 3D printing, and the AMES program.

Elsewhere, Tech Soft 3D, a provider of Software Development Kits (SDKs), is using its HOOPS Platform to help Proplanner integrate 3D model data into its Assembly Planner software. The collaboration has allowed Proplanner’s customers to better plan their engineering workflows and consolidate 3D model data.

3D printer manufacturer Coherent, and dental CAM software developer exocad have started working together to simplify and improve the digital workflow of dental professionals. The partnership will see the development of a simple data interface between exocad’s DentalDB software, and Coherent’s DENTAL COCKPIT slicer.

Nominations for the 2020 3D Printing Industry Awards are still open, let us know who is leading the industry now.

The fourth edition of the 3D Printing Industry Awards Trophy Design Competition is now underway. Enter your design for the chance to win a CraftBot Flow 3D printer.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Ultimaker S5 system being programmed using the company’s Essentials software package. Image via Ultimaker.