Imagine your life is to illustrate the inner workings of some of the world’s most fascinating machinery for some of the most popular science magazines. Now imagine how much better 3D printing can make your work if you muster the art of 3D modeling as well. That is what Don Foley, known and talented illustrator for the likes of National Geographic and Popular Science, did.

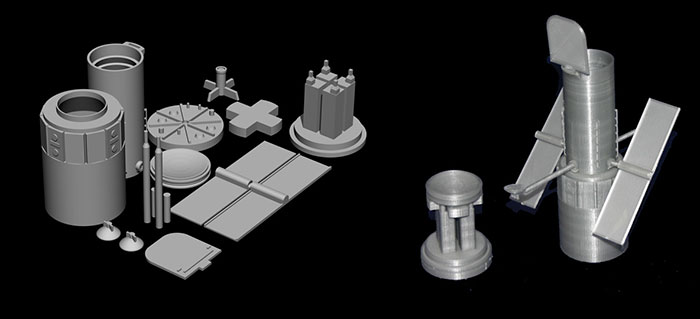

What bonds all these illustration masterpieces together, along with the fact they they are fully 3D printable and can be assembled, is that Don used Simplify3D software to import, repair, slice, preview and produce the object’s many parts as a single print.

“Before I learned about Simplify3D, I had one failure after another,” he admitted. “I would design an entire print bed of parts, but when one piece failed, the whole board was ruined. I was reduced to printing one part at a time and was going crazy.”

With Simplify3D software, Don is able to fill the entire build plate with parts. He reported that he no longer needs to use rafts and is more confident that the complex multiple parts will print successfully even without supervision. He also has more control over the precision quality and detail he needs.

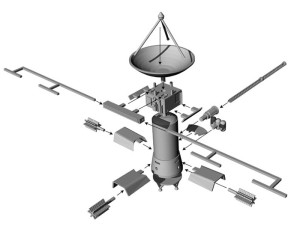

The new Double Bubble project for Popular Science is a fantastic demonstration of what can be achieved. The complex 3D aircraft model, designed by MIT in 2010 to carry 180 passenger to Mach .74, is chronicled through renderings, 3D modelling diagrams, 3D printing STL files, assembly diagrams and decals.

This is how Foley describes the project in the online article, which is a de-facto preview of the paper version, due out in the June issue:

“When Popular Science gave me an assignment to illustrate a concept plane for the magazine, I saw it as an opportunity to showcase my latest skillset, 3D printing … The idea I pitched to the magazine was that they could put the 3D printable STL files on their website so readers at home, or students at school, could 3D print something they read about in the magazine. As far as I knew, nobody had done this before.”

The famous illustrator is not the only 3D printing pioneer to adopt Simplify3D software for complex projects: recent success stories include the Louisville heart model, Buttercup the Duck, and the Cyborg prosthetic hand. In all cases, the 3D designers were approaching 3D printing to try something that had never done before: simplifying the 3D printing aspect is a necessary first step.