The D3D team is back on Kickstarter with another 3D printing innovation. Whilst developing the idea for their previous project the team discovered that rigid mounted hot ends could create quality prints, but had limited ability to offer high resolution when printing with two colours. This showcased the need for high performance hot ends that could prevent dragging, eliminate stringing and break the 100 micron barrier.

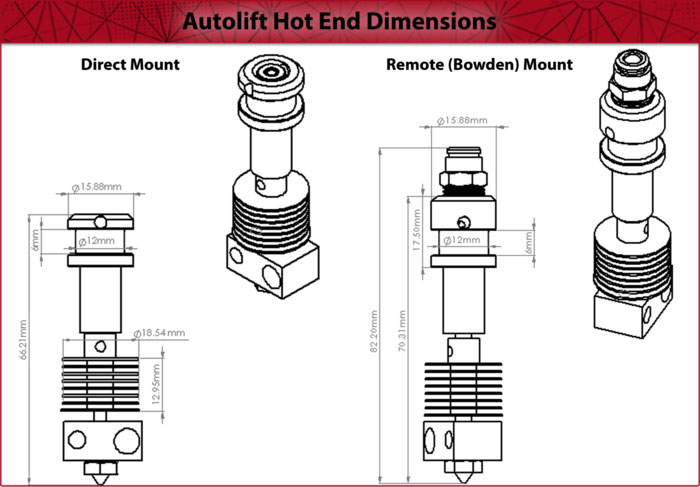

The AutoLift system automatically lifts the nozzle during filament retraction, eliminating dragging and preventing the deposition of extra plastic.Autolift comprises of a micro linear bearing and spring to activate the retracted nozzle position. The systemis designed to function as part of the standard filament retraction operation. Thesystem isadjustable to allowthe user to fine tune the amount of retractiondepending on theprinting objectives.

Those features:

- All-metal design for high temperatures

- Micro linear bearing

- 1.75mm or 3mm filament

- 40w cartridge heater included

- 300º C thermistors included (500º C optional)

- 0.35 mm nozzle included

- No Kapton Tape required: The thermistor & heater use setscrews

The team has tested the system with many materials including, ABS, PLA, PVA, Nylon, HDPE, a few custom materials and haw experienced outstanding results with all materials. D3D’s funding goal is set at USD$10,000, this allow them to purchase materials involume to keep production costs low. You can catch their Kickstarter campaign here.

Or check out the video below: