Researchers at the University of Amsterdam, Utrecht University, TU Delft and Unilever’s Innovation Centre have harnessed the power of 3D printing to perfect the texture of chocolate confectionery.

Specifically, using topology optimization, the scientists have managed to tailor the way in which 3D printed edibles break once bitten into, to make them more pleasurable to eat. Having applied their approach to develop a tastier form of chocolate, the team say that in future, it could be used to improve the “mouthfeel sensory experience” of other foods as well, unlocking a shift in culinary perceptions.

Exploring ‘mechanical metamaterials’

It may go without saying, but being able to control the taste, texture and overall sensory experience of eating foods is vital to making them appealing. While the scientists highlight this as something that affects everyday snacking items like soups, yogurts and crackers, it’s also an issue that tends to prevent people from eating healthier or meat-free meals, which can be seen as less appetizing.

In an effort to make such foods more palatable, a rising number of lab-based start-ups and research groups are beginning to experiment with customizing them via 3D printing. Just last year, MeaTech revealed that it had 3D bioprinted a 3.67 oz steak, while more recently, a team at the Singapore University of Technology and Design (SUTD) has developed a means of 3D printing with protein-rich okara.

Where the Netherlands-based team’s approach differs from that of its predecessors, is that it has seen them focus on ‘mechanical metamaterials.’ In previous research, these man-made materials have shown programmable shape-changing properties, potentially making them an ideal basis for creating novel objects with tunable fracture and strength qualities.

However, according to the scientists, little is known about how metamaterials can be used to control mouthfeel, and the sensory experience of diners upon biting into them. To rectify this apparent shortcoming, the team has therefore turned to 3D printing in a bid to develop chocolate-based shapes with custom geometries, designed to break in a way that makes them more pleasurable to eat.

Tastier food via topology optimization

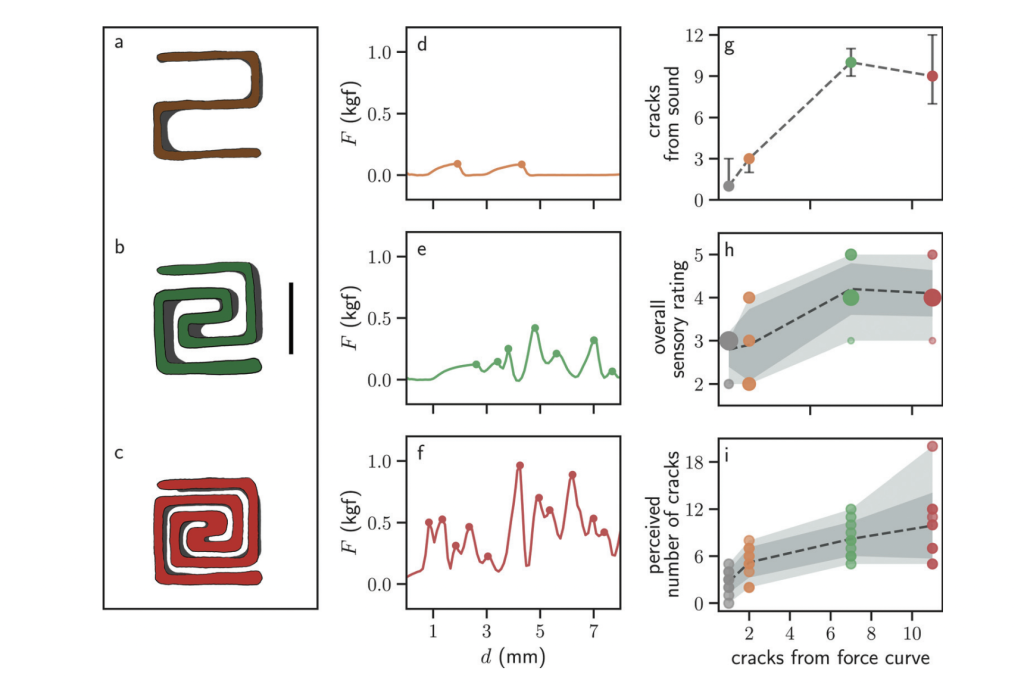

Initially, the researchers designed an S-shaped confection, but this was found to feature a very different fracture behavior depending on whether it was compressed along one axis or another. Given that this would probably lead to inconsistencies in the way people who ate the chocolate in future were likely to enjoy it, the team opted to use their findings to develop a spiral-shaped edible instead.

Interestingly, in doing so, the scientists discovered they could tune the number of ‘fracture and self-contact events’ by adjusting the amount of ‘winds’ in their design. When fed to a crew of ten taste testers, the team also observed that the amount of audible cracks the chocolate made when bitten, had a positive impact on perceived eating pleasure.

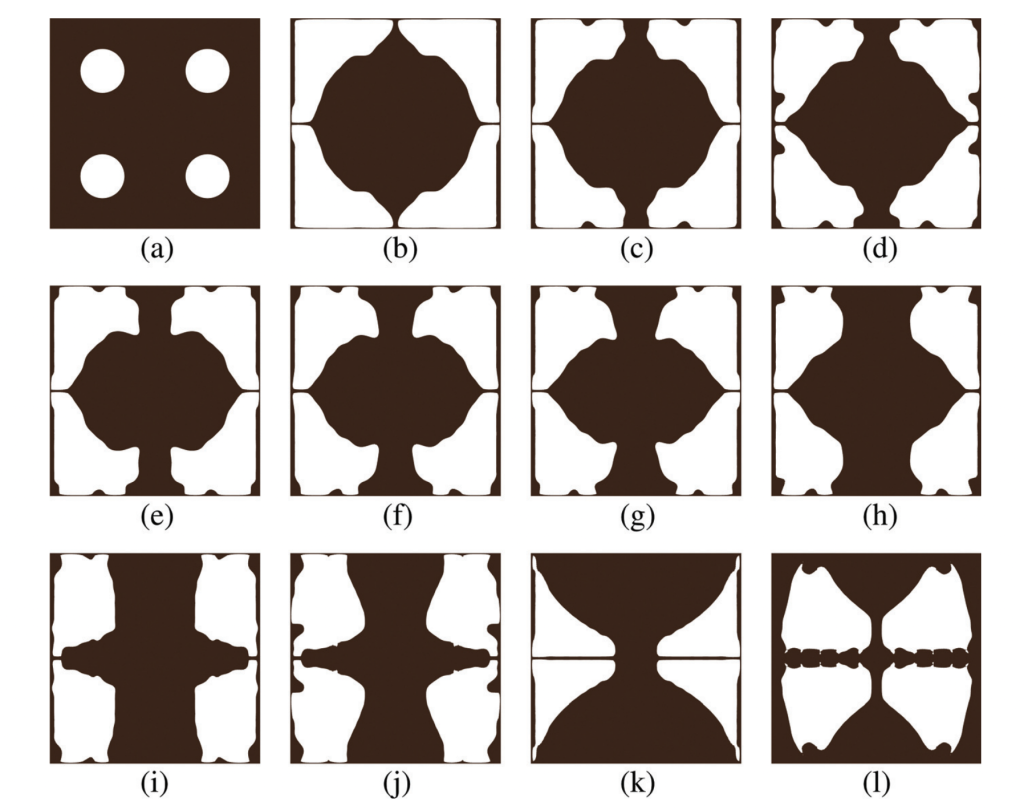

Having established the potential of mechanical metamaterials to influence diners’ enjoyment of meals, the researchers then took their approach a step further, by using a topology algorithm to create “maximally anisotropic structures.” These designs featured more intricate patterns, which could be made tougher to bite in one direction than another, thus demonstrating their approach’s precision.

Although the team’s research did come unstuck at times, with the syringes of its ETEC 3D Bioplotter platform occasionally clogging with chocolate, they still maintain that they’ve proved it possible to “control some features of the mouthfeel sensory experience,” in a way that could “open the door to new approaches” to human-matter interactions moving forwards.

Though it may not be the first application of the technology that comes to mind, 3D printing has been used at an experimental level to produce chocolate snacks many times before. At SUTD, researchers have come up with a way of 3D printing milk-based desserts, and used it to produce sweet treats with different levels of chocolate, syrup and coconut fillings.

Food 3D printer manufacturer byFlow, meanwhile, has demonstrated the capabilities of its patented printhead by 3D printing personalized chocolate. Showcased at the World’s 50 Best Restaurants Awards 2021, the technology essentially works by balancing the temperature of the printhead’s different zones against environmental conditions, to ensure consistent food-printing results.

Elsewhere, studies have also been conducted into adjusting the taste of various dishes by 3D printing instead of cooking them. In one such project, scientists at Columbia University have even come up with a way of 3D printing unusual food mixtures from multiple ingredients, allowing them to develop new flavor profiles.

The researchers’ findings are detailed in their paper titled “Edible mechanical metamaterials with designed fracture for mouthfeel control,” which was co-authored by André Souto, Jian Zhang, Alejandro M. Aragón, Krassimir P. Velikov and Corentin Coulais.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a pile of chocolate and cocoa beans. Photo via Tetiana Bykovets, Unsplash.