Researchers from the Singapore University of Technology and Design have developed a novel method of 3D printing milk-based desserts, that prevents them from being spoilt at room temperature.

Although extrusion-based techniques are now used to commercially fabricate foodstuffs, they often emit too much heat to allow their use with temperature-sensitive ingredients such as milk. Rather than changing the overall printing process to overcome this, the team found a way of adjusting the rheological makeup of powdered milk and created an edible new range of inks.

Leveraging their novel dairy-based 3D printing materials, the Singapore team managed to rustle up a variety of culinary delights, raising the prospect of further gourmet innovations in the future.

“We found that using a cold-extrusion method did not compromise the milk’s temperature-sensitive nutrients,” said Michinao Hashimoto, co-author of the study. “The technique offers vast potential in the 3D printing of aesthetically-pleasing, nutritionally-controlled foods which are customized for individual requirements.”

“This novel yet simple method can be used to formulate various nutritious foods, including those served to patients in hospitals for their special dietary needs.”

The emerging additive edibles industry

Additive manufacturing is well-established within the industrial, automotive and aerospace sectors, but one of its lesser-known applications lies in the creation of enhanced, custom-designed foods. Leveraging 3D printing, it’s now possible to tailor a meal’s nutrients depending on the needs of those eating it, raising the prospect of foods that are tuned for sufferers of certain diseases.

Researchers from the University of Technology Sydney (UTS) and Deakin University in Australia for instance, have 3D printed meals that are safer to eat for people with swallowing disorders (dysphagia). In recent years, additive techniques have also been used to produce a number of animal-free meats, such as Redefine Meat’s fabricated steak, and Legendary Vish’s printed salmon.

More often than not, extrusion-based printing methods are used to create such fabricated foods, due to their low-cost, flexibility, and ability to dispense liquid-based food materials. The downside of extruding edibles is that FDM 3D printers can get very hot during operation, and this makes them incompatible with products that need to remain cold such as milk.

In order to protect milk’s temperature-sensitive nutrients, it’s possible to use cold-extrusion techniques instead, but these require the addition of food additives, which alter the rheological makeup of the liquid. Previous studies have shown that such additives can provide greater structural integrity to printed products, but judicious optimization is required to achieve a good level of printability.

To overcome the time-consuming drawbacks of additive-oriented approaches, the team proposed a new method, which extrudes customized food inks with tailored rheological properties, and without the use of additives.

The Singapore team’s milk-based food inks

In order for an ink to demonstrate good usability for 3D printing food products, the research team identified two key factors: it needed to exhibit shear-thinning behavior, and it had to maintain its shape after deposition. To find the ideal ink composition, the team proceeded to create a number of inks with a variety of rheological properties and tested them by printing a range of mesh-like structures.

Material mixtures ‘M70’ and ‘M75’ showed a high level of yield stress, which proved vital, as they were capable of being used to create solid structures, while other samples just dripped from the nozzle. A number of other parameters such as dispensing pressure, and nozzle velocity and diameter, also proved to be vital to print fidelity and showed that print settings remained a factor in culinary success.

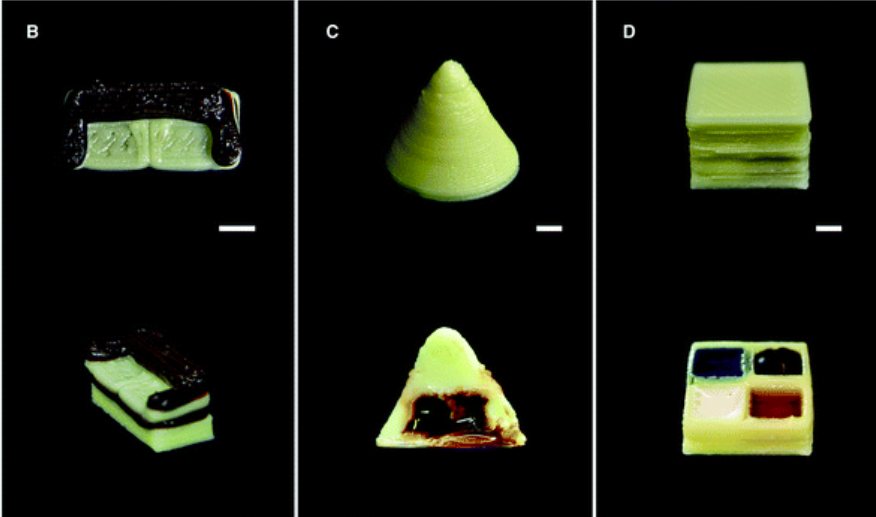

The team went on to evaluate their milk inks by fabricating everyone’s favorite after-dinner meal, a couch, and the same two mixtures had the strength to stand alone without deforming. Following the success of their initial additive sofa tests, the researchers experimented with producing a range of other shapes, using a multi-ingredient method.

Leveraging a Direct Ink Writing (DIW) 3D printer, armed with syringes containing multiple food inks, the team printed the shapes, but this time containing different layers of chocolate, coconut, and syrup. In order to further test the abilities (and tastiness) of their technique, each level of the team’s fabricated dessert menu had a different texture too.

Voids were integrated into some of the structures to allow for printed chocolate fillings, and the two strongest variants of the researchers’ inks remained able to stay compact without the need for additives. As a result, the team considered their inks to be a success, as they had successfully developed an optimized, simpler, and less time-consuming alternative to using additives in 3D printed foodstuffs.

Disappointingly though, the team considered the future applications of their novel inks to lie in the medical sector rather than the food industry, meaning that they’ve likely printed their first and last ever chocolate sofa.

The researchers’ findings are detailed in their paper titled “3D printing of milk-based product,” which was published in the RSC Advances and co-authored by Cheng Pau Lee, Rahul Karyapp, and Michinao Hashimoto.

Nominations for the 2020 3D Printing Industry Awards are still open, let us know who is leading the industry now.

The fourth edition of the 3D Printing Industry Awards Trophy Design Competition is now underway. Enter your design for the chance to win a CraftBot Flow 3D printer.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the researchers’ 3D printed chocolate sofa. Photo via the RSC Advances journal.