MSC Software Corporation (MSC), a Californian developer of computer-aided engineering (CAE) and simulation software, and RMIT University, have signed an agreement.

Based in Melbourne, RMIT University’s Advanced Manufacturing Precinct will use of MSC’s Simufact Additive to research and develop metal additive manufacturing processes. The partnership is hoping to help accelerate the use of additive manufacturing in Australia.

“RMIT’s Advanced Manufacturing Precinct is leading the way in shaping the future of additive manufacturing locally with breakthrough research,” said Sridhar Dharmarajan, Managing Director, Indo-Pacific Region, MSC Software.

“Therefore, it gives us great pleasure to note that some of the best additive manufacturing minds of the future will have an opportunity to work with and understand MSC Software’s Simufact Additive before they embark on their professional careers.”

Simufact Additive

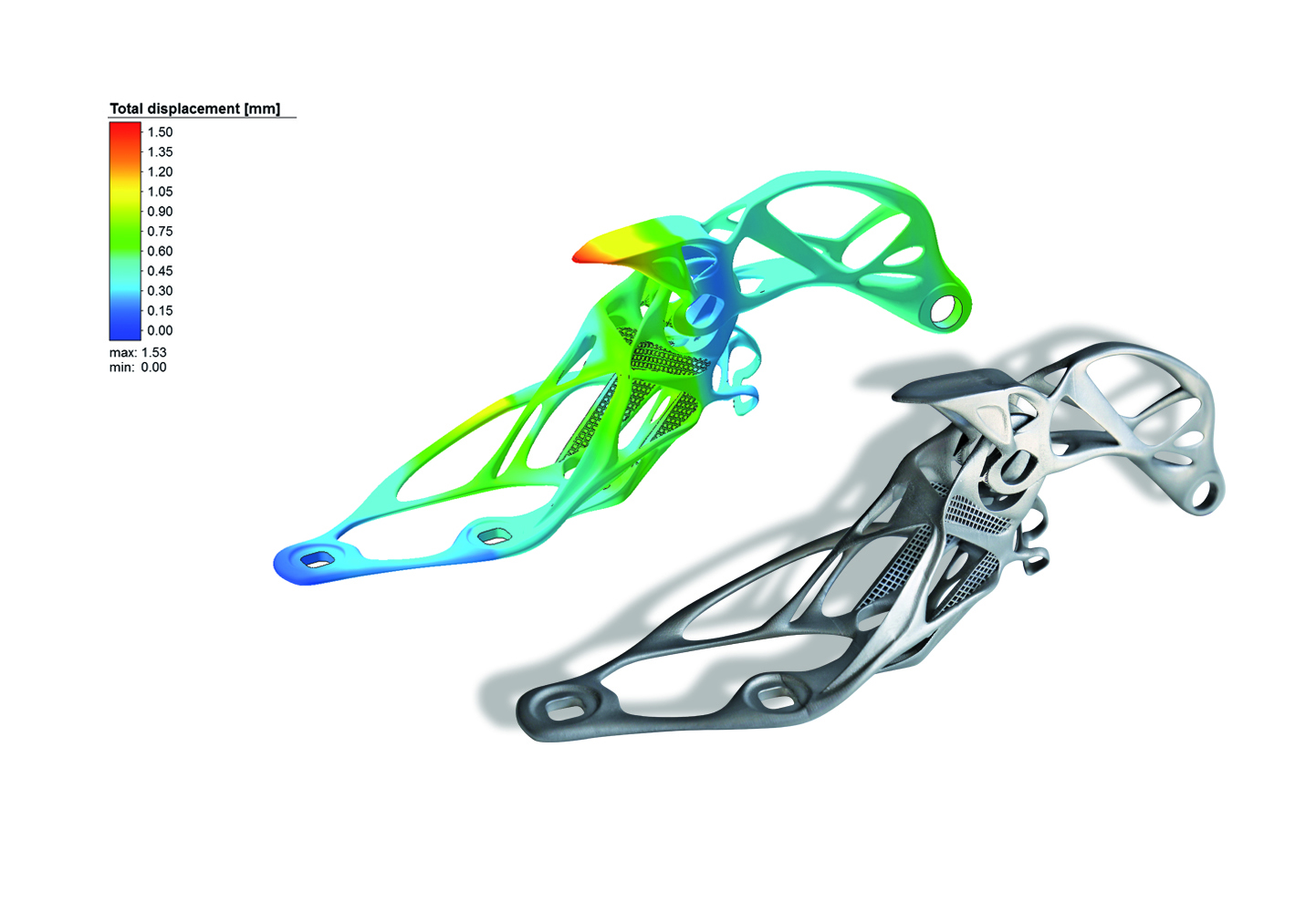

MSC’s Simufact software is divided into three versions: Simufact Forming, Simufact Welding and Simufact Additive. The latter is designed to run simulations, distortion predictions, and FEA analysis’ for laser powder bed fusion (PBF) additive manufacturing processes.

Most recently, BAE Systems acquired the Simufact Additive software to reduce build trials for 3D printing metal aerospace components. Prior to this, the software was selected by the European Organization for Nuclear Research (CERN) to aid the application of selective laser melting (SLM) 3D printing processes.

Elaborating on the capabilities of the stimulation software, Dr. Hendrik Schafstall, Managing Director and CEO of Simufact, stated, “Simufact Additive’s capabilities range from generative design & topology optimization, to process simulation and post processing. This allows one to generate optimized components that are perfectly adapted to the operating conditions and ensure 3D printers can successfully produce the generated design.”

Simufact Engineering on YouTube.

RMIT University and industrial additive manufacturing

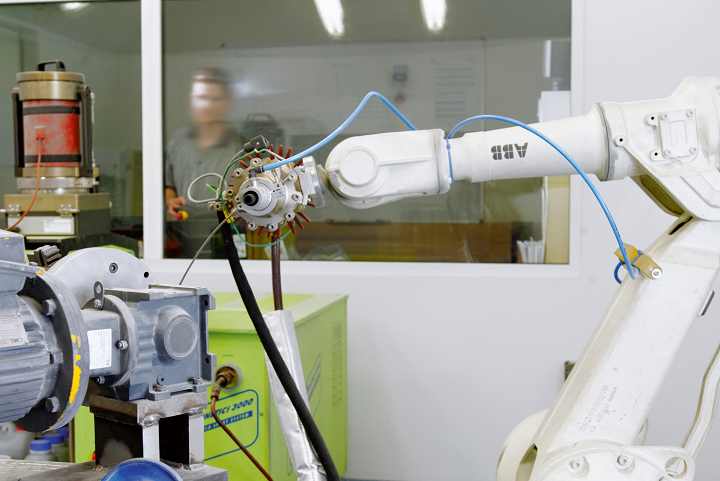

Research from the Royal Melbourne Institute of Technology, or RMIT University, has shown advancements in metal additive manufacturing. Late last year, Professor Milan Brandt, Technical Director at Advanced Manufacturing Precinct, RMIT University, commenced a project applying laser metal deposition to cut down the cost of maintenance, repair & overhaul (MRO) operations related to the Australian Defense Forces.

Regarding its adoption of the Simufact software Professor Brandt explained, “Our vision is to be the leader in the implementation of the next wave of manufacturing in Australia. To this end, we believe in working closely with the best in the industry, both in Australia and internationally; as we go about developing the next generation of engineers, designers and technicians for the world.”

“MSC Software’s Simufact Additive combines the best approaches in one unique software solution through a multi-scaling approach. We find it extremely valuable as it lays the foundation for a wide variability and scalability through different levels of detail for the simulation results.”

RMIT University reportedly houses one of the largest Advanced Manufacturing Centers in Australia.

Stay abreast of the latest additive manufacturing news by subscribing to the 3D Printing Industry newsletter, and following us on Twitter and Facebook. Also, join 3D Printing Jobs now for new opportunities in engineering.

Featured image shows the simulation of bracket distortion using Simufact Additive. Image via MSC Software.