New York based technology company WAZER was founded in 2015 by four Penn Engineering coursemates seeking to commercialize their desktop water cutter project. In this article we review the resulting product, the WAZER water jet cutter.

This desktop sized water jet cutter is built by and for engineers, and possesses an operating pressure of around 4,000 psi, allowing it to cut a wide range of materials for a variety of applications. This machine is particularly easy to operate, disassemble, and repair, making it more accessible than other cutters on the market. Since its release in 2018, WAZER has scaled production and now ships compact and affordable waterjet cutters to customers worldwide. The 3D Printing Industry engineering team visited Solid Print3D to put WAZER’s claims to the test.

Key features and technical specifications:

Measuring only 856 x 648 x 551mm for the desktop version and 856 x 548 x 1220mm when incorporating the optional stand, the WAZER is especially compact. The machine’s small footprint, combined with its impressive cutting power, makes it accessible to a range of users outside of industrial workspaces.

With traditional water jets costing upwards of $100,000, the WAZER’s price tag of $9,999 makes it an affordable option. Indeed, WAZER is the first true entry level water jet cutter, with no other water jet machines currently on the market that can compete with this price.

The WAZER is primarily targeted at small businesses looking to speed up production and increase the quality and accuracy of their cuts. The machine is also accessible to other customers, such as schools and DIY hobbyists, who would otherwise be unable to acquire industrial water jet cutting systems.

Capable of cutting various materials, including metals, glass, plastic, composites, tile, rubber, and foam, WAZER is a versatile machine and offers usability for numerous applications. Its cutting area of 305 x 460mm may seem limited in comparison to the much larger industrial water cutters on the market. However, given WAZER’s impressively small footprint and low price-point, this modest volume would certainly meet the needs of target users.

The company offers fantastic customer service and resources, providing expert in house assistance to users who have encountered problems with their machine. This relationship makes it feel as though you are working with the company, which we see as a big bonus. The whole machine can be disassembled and, with the plethora of resources offered via the WAZER website, easily repaired.

Unboxing and kit contents:

We are pleased to report that the WAZER came well packaged, enclosed inside a large plywood crate atop a large pallet.

Each WAZER machine is hand-assembled by production staff on site at their New York factory, undergoing 120 separate quality tests prior to shipping. With each individual section of the machine encased in foam to add extra protection during shipping, this level of care clearly does not end once the product leaves the factory floor.

Unboxing the WAZER. Photos via 3D Printing Industry.

The package included: 2 buckets of abrasive; a water filter; an accessories box; 4 replacement cut beds; a pump box; 2 water sensors; a stand; and the WAZER cutter itself. The stand is an optional extra, costing an additional $1,299, but can significantly increase usability by adding storage and making the machine easier to move.

The package also included a setup kit and an accessories kit, including all the tools and accessories required when setting up and using the WAZER. The addition of multiple spare parts, such as washers, taps, and any other parts that may fail during the WAZER’s lifetime, was a nice touch.

The included user manual was one of the most comprehensive we have ever seen, with almost any problem you are likely to encounter being addressed. Whilst the WAZER comes mostly pre-assembled, the machine’s pump system does need to be manually connected to the main water supply. The included manual and online resources make this step accomplishable by most, if not all, customers.

Package contents. Photos via 3D Printing Industry.

Hardware and architecture:

Architecturally, the cutter possesses three stepper motors to control movement. Two are located on either side of the X-axis frame controlling Y-movement, and one inside the jet module which controls X-axis movement.

To ensure safety, the whole machine is enclosed, and cannot be operated when the lid is open. When operational, water is jetted onto the material and ricochets vigorously until the material is pierced. This enclosure ensures that any sprayed water & abrasive cannot escape the machine.

The WAZER sports a sleek main body made from steel, aluminum extrusions, and plastic. The aluminum frame is strong and sturdy, with designated cutouts enabling the machine to be easily maneuvered.

The WAZER body and frame. Photos via 3D Printing Industry.

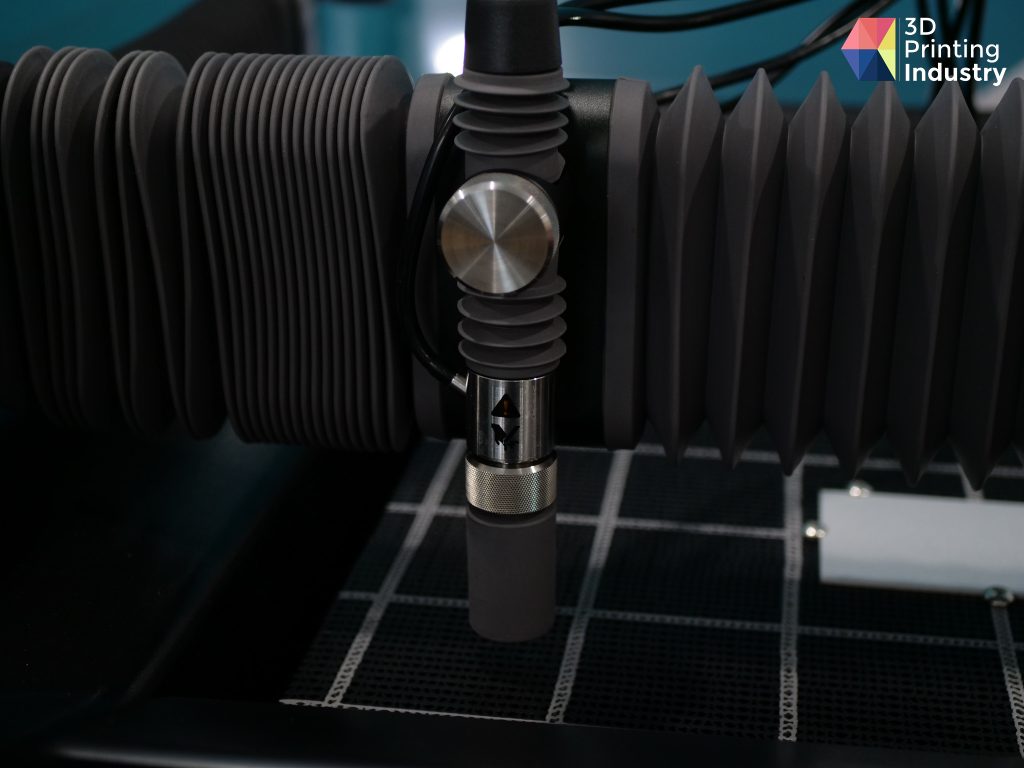

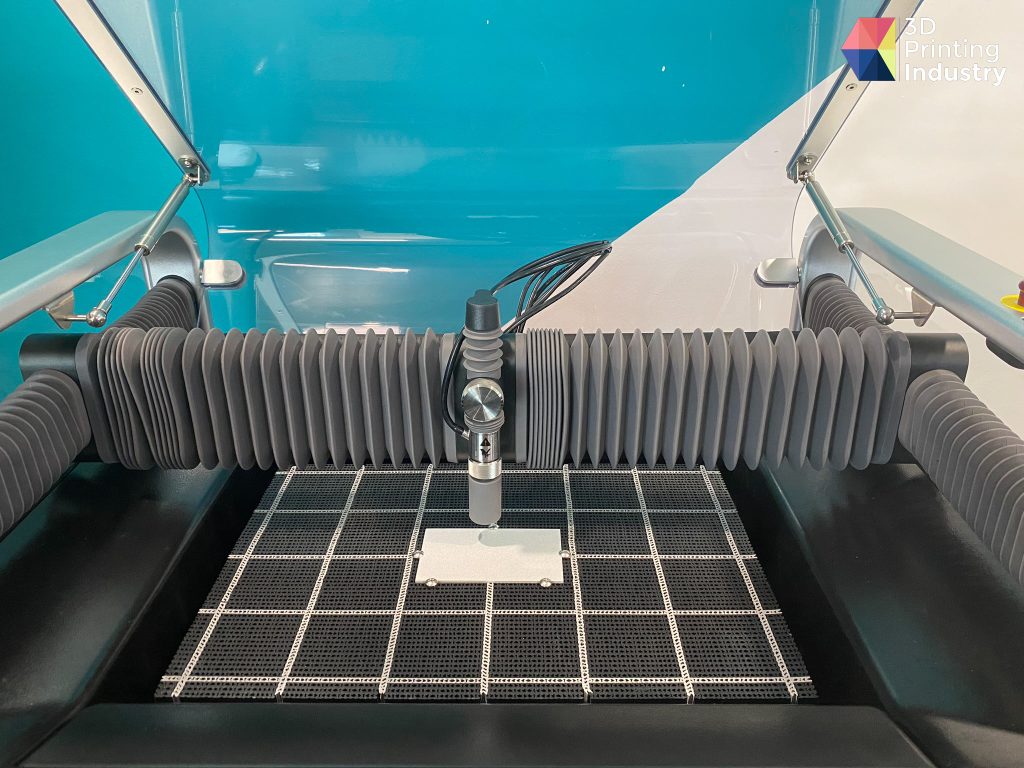

The machine uses a singular nozzle to cut material, the water and abrasive being combined in the mixing tube which has an internal diameter of 1.1mm. The nozzle is adjustable, and can be manipulated on the Z-axis to an appropriate distance from the part. With a diameter of 0.48mm and made from ruby or sapphire, the nozzle is of a high standard.

The separate pump box controls the water pressure of the WAZER, and plumbs in through the rear of the machine. Measuring 533 x 379 x 251mm and weighing 42kg, the pump box can be situated wherever suits the user, however must be appropriately supported if on a bench due to its weight.

Much like the cutter, the pump box possesses a sleek design. We were impressed by the internals of the pump, as with the rest of the system, due to its high build quality and attention to detail.

The WAZER pump box. Photos via 3D Printing Industry.

Made from the same extruded aluminum material as the WAZER, the stand is extremely easy to assemble and attach to the machine. The stand also provides additional storage space and an optimal location for the pump box to sit, making for an all-round compact package.

Shipped with a pre-installed cut bed. Made from corrugated polypropylene sheets, these beds are consumable and last for approximately 20-50 hours, depending on the cutting patterns and materials. These beds can also be flipped over to extend their lifetime.

The Wazer includes a small LCD screen for operation. Located on the right-hand side of the unit, this screen is controlled by four directional buttons surrounding a central select button. A start/stop button is incorporated to be used when cutting, whilst an E-stop button is also available to stop a cut in an emergency.

The WAZER offers a clear and straightforward user experience, with all operations managed through the LCD screen for the whole cutting process. Prior to starting a cut, the machine offers the option for the cutter head to jog the extremities of the design, or perform a dry run to check that all pieces are within the material boundaries. This feature is particularly useful, with the dry run able to restart the cut halfway through the nozzle’s journey if the cut fails.

The WAZER also automatically homes itself once the cut file is selected, whilst the machine will also re-home accurately following an e-stop or shutdown.

Customer Service:

WAZER has a very close relationship with its customers, offering an extensive support system for all users to help them with any problems they may have while using the WAZER system.

The first port of call for users looking for support is through the WAZER website, where extensive resources and links can be accessed for any issues or faults encountered with the machine. Additionally, e-mail support is available via an online form, whilst phone and video-call options are also available.

We found the WAZER team to be very helpful, friendly and informative, with WAZER being incredibly honest and open with its customers.

Cutting software (WAM):

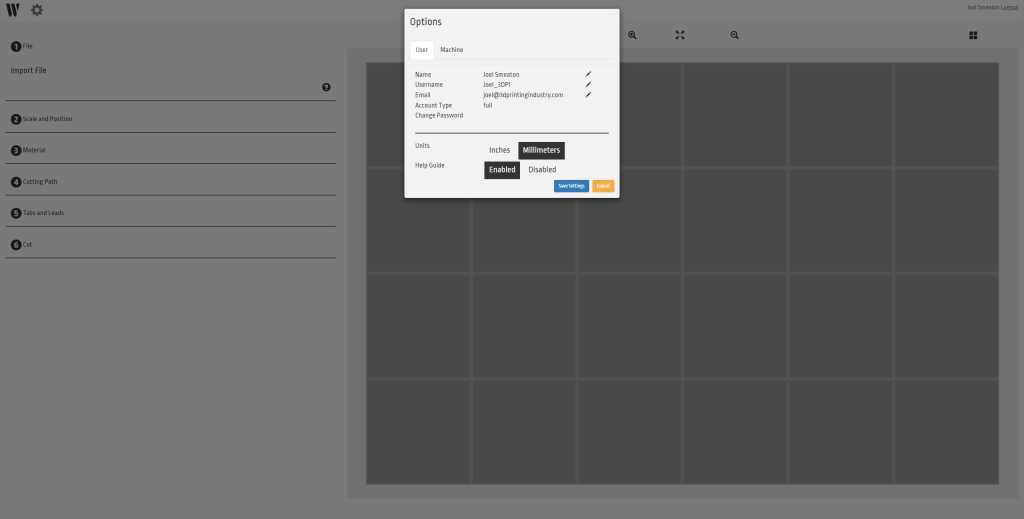

WAM, a cloud based program, is the software provided by WAZER. Accessible through a computer browser, WAM does require a strong Wi-Fi connection to function, which could pose problems for users who do not possess strong internet connection. Yet, when accessed, WAM is easy and simple for both the company and user to manage. Files can be imported and exported, scaled and positioned, materials selected, cutting path determined, and tabs added manually or automatically within WAM.

Whilst WAM’s general UI is user-friendly, the process for scaling and positioning does not offer the ability to drag or reposition the design. Instead, the user must enter the positioning and scale manually within the menu. Whilst this does work, the addition of greater control would certainly improve the overall usability of the software.

The WAM landing and scale and positioning pages. Photos via 3D Printing Industry.

Test projects and potential applications:

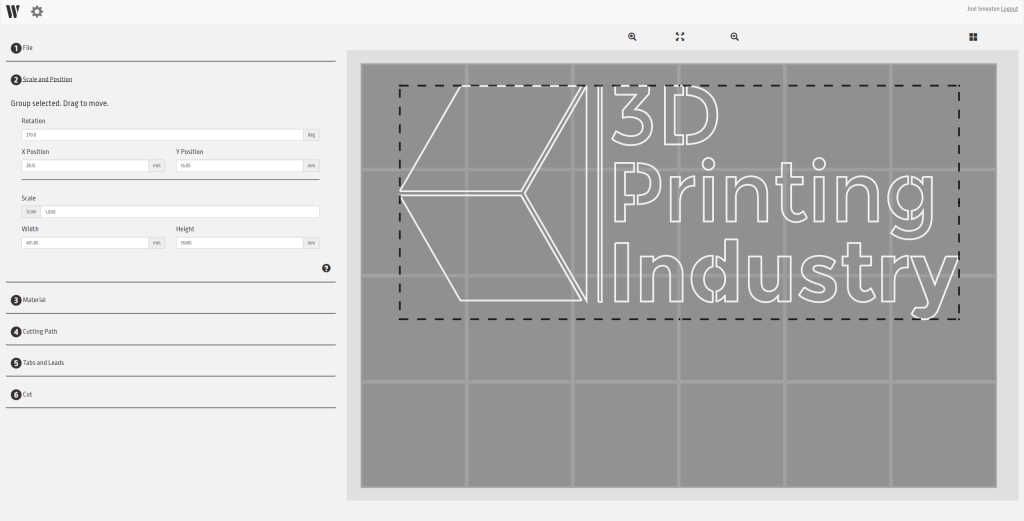

To fully assess the functionality and potential applications of the WAZER cutter, we conducted a number of test projects, the first of which being a HDPE 3D Printing Industry spray paint stencil.

The results of this test came out as expected. Whilst laser cutters often melt acrylic at the contact point leaving behind surface defects, waterjet cutters cut straight through with no artifacts left behind. This is a significant advantage offered by the WAZER.

Spray paint stencil. Photos via 3D Printing Industry.

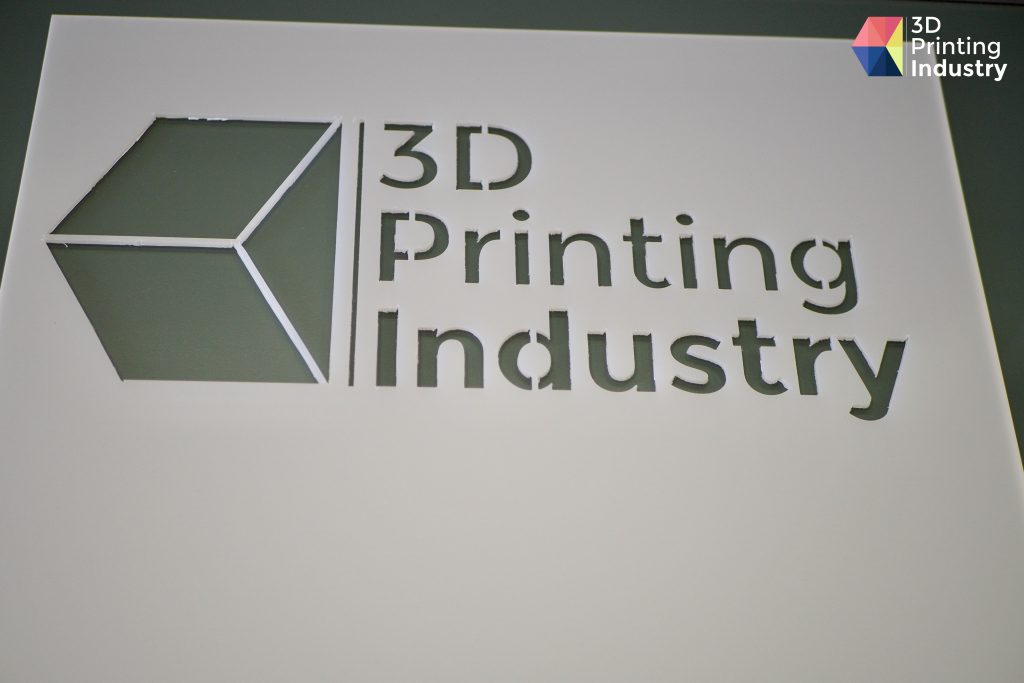

To showcase the WAZER’s ability to cut precise and neat copper parts, we chose to cut a copper gasket.

This test provided very impressive results, with no surface marks or inaccuracies. This test was easy to set up and yielded a fully functional part, a success for the WAZER.

Copper gasket test piece. Photos via 3D Printing Industry.

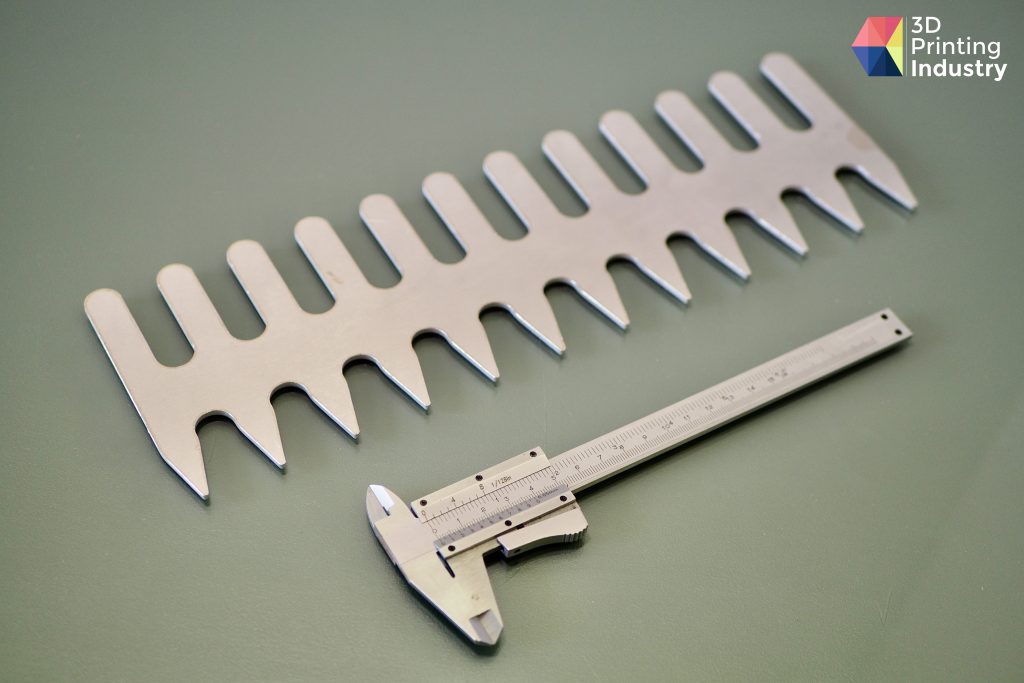

Next, we conducted a test cut of a chain sprocket using 3mm thick aluminum, allowing us to assess WAZER’s accuracy with thicker materials. This piece came out brilliantly, each section being cut perfectly with no visible stream lag. Another success for the WAZER.

Aluminum Sprocket test piece. Photos via 3D Printing Industry.

Next, we produced an aluminum dovetail routing jig with 3mm thick aluminum. Once again, this part came out very nicely, providing a clean cut all the way around the part.

Dovetail jig test piece. Photos via 3D Printing Industry.

We next produced a stained glass window, with the aluminum frame and stained glass panes cut using the WAZER. The glass components produced great results, with no failed cuts and no issues during processing.

The tabs on the aluminum parts did not secure very well to the pieces, with the cut having to be paused three times to remove loose parts and reduce any collision risk with the cutting head. This was a successful test, although highlighting small room for improvement.

Stained glass window test piece. Photos via 3D Printing Industry.

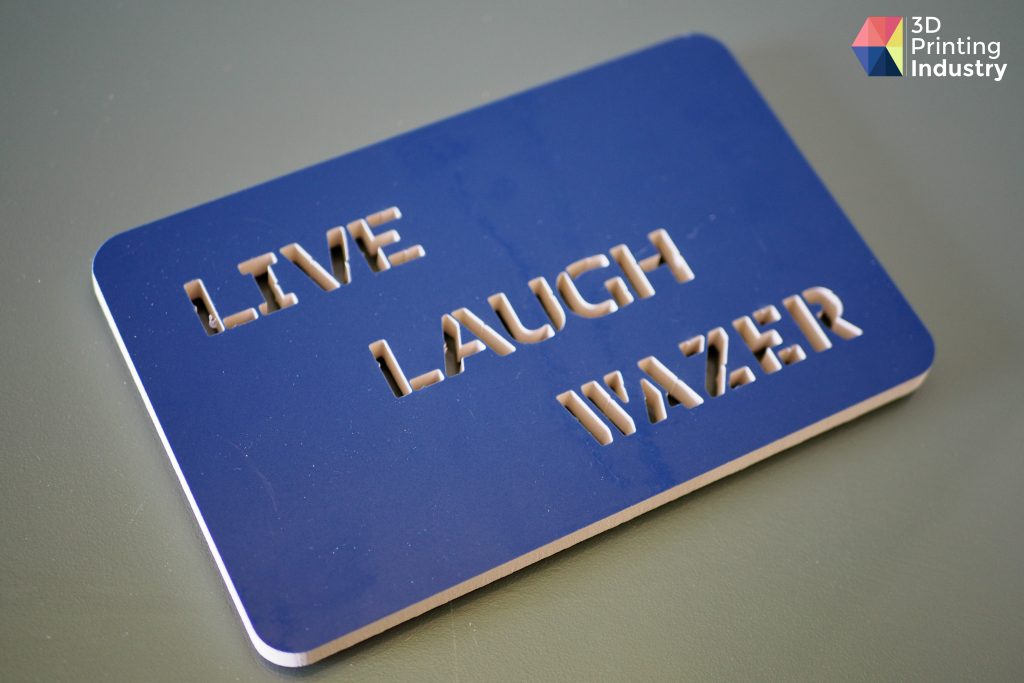

We also produced a “Live, Laugh, WAZER” sign using an 8mm thick piece of ceramic. This cut perfectly, producing very good results in a fraction of the time compared to alternative methods, such as laser cutting or hand carving.

Live, Laugh, WAZER test piece. Photos via 3D Printing Industry.

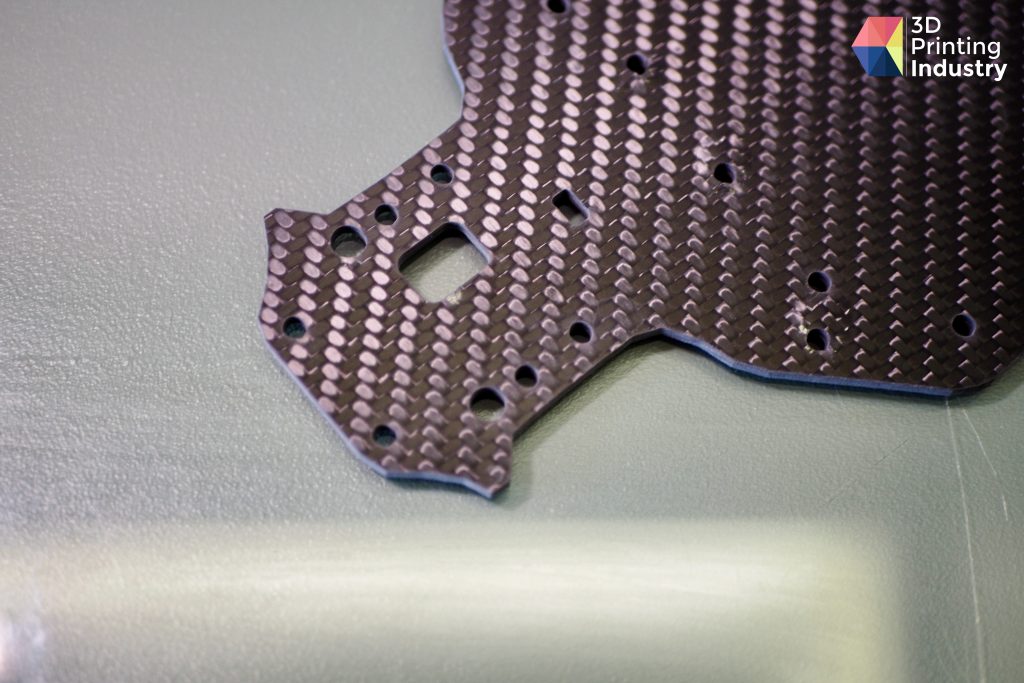

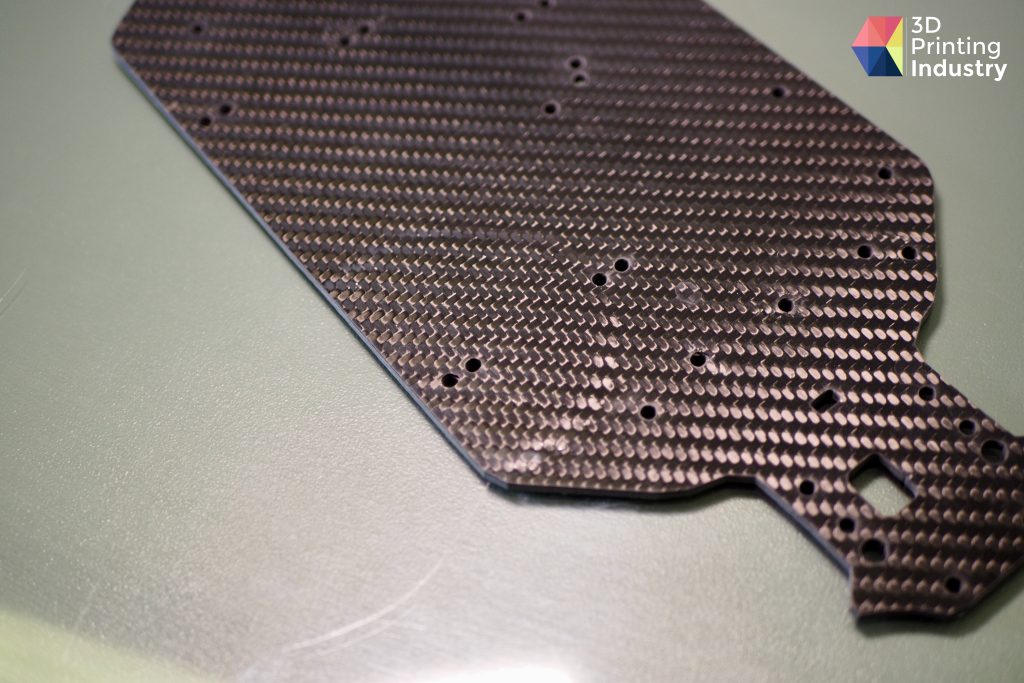

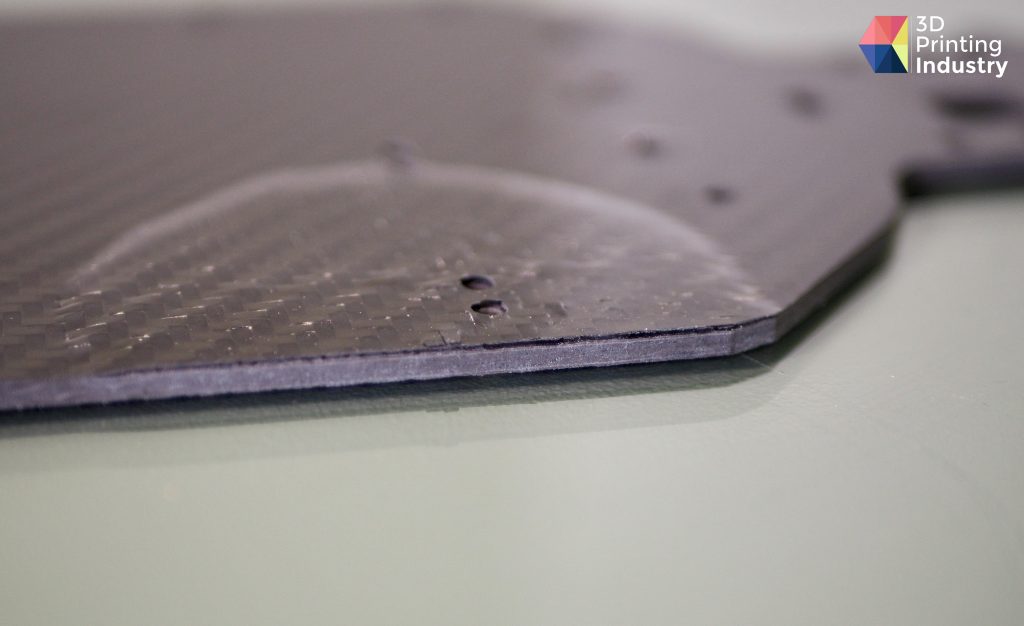

Next we tested the WAZER’s ability to cut hardened composite materials, using carbon fiber sheeting to produce an RC car chassis plate.

Whilst this cut was acceptable, there was some delamination to the layers atop the piece. This was caused by water getting in between the two sheets of carbon and resin. WAZER has confirmed that this is a possible defect when using laminate materials, due to the stresses induced by the jet during piercing. This issue may also be attributable to material suppliers performing laminations in multiple operations, causing weaker bonds between layers.

Ultimately, we can confirm that the WAZER is capable of handling carbon fiber materials.

Carbon fiber RC car plate test piece. Photos via 3D Printing Industry.

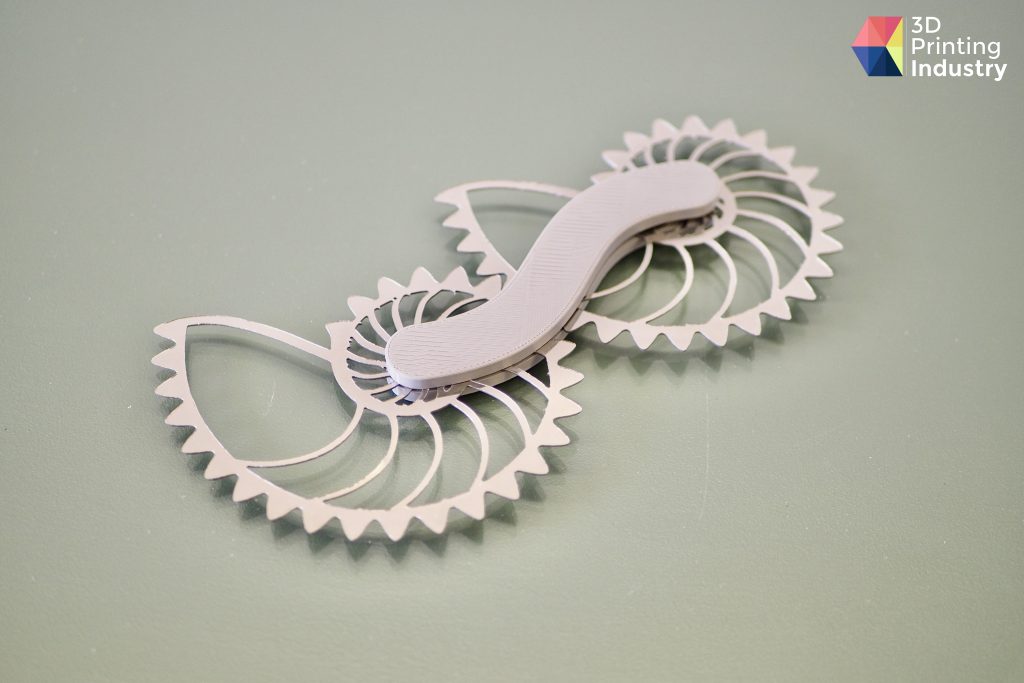

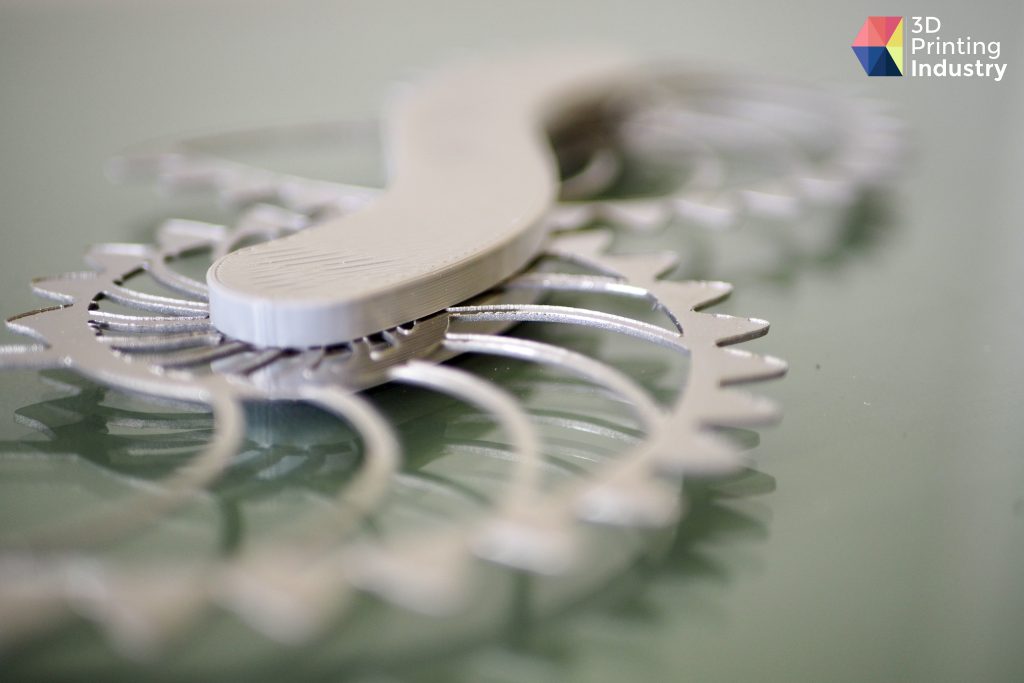

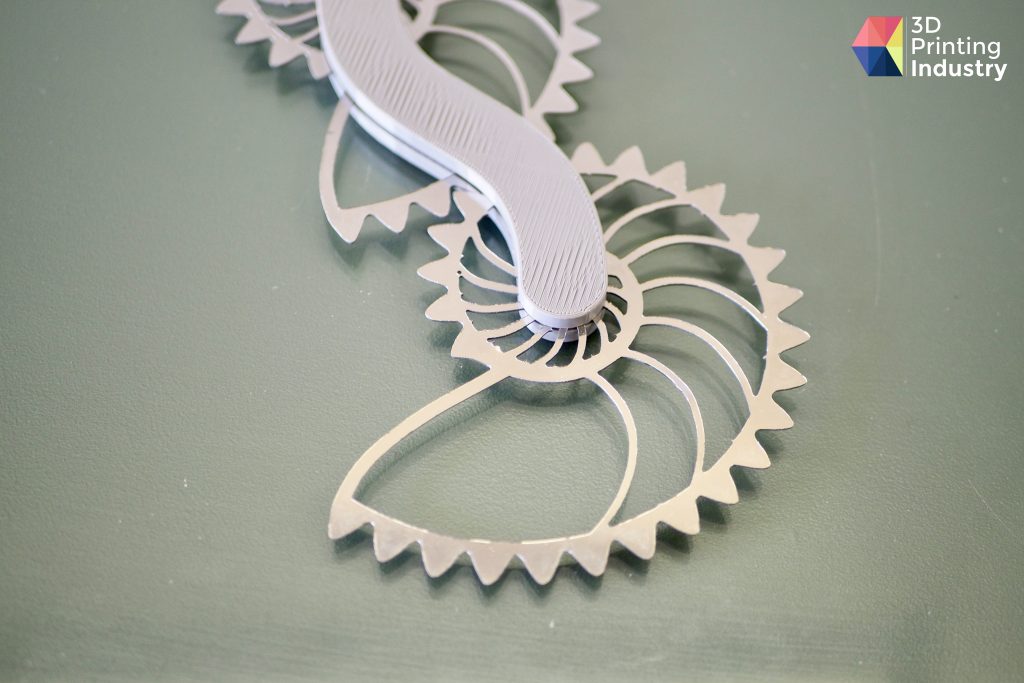

Mirrored surfaces are sometimes hard to cut with certain types of lasers. Therefore, we next tasked the WAZER with cutting nautilus gears, a mathematical shape that follows the Fibonacci spiral, out of mirrored stainless steel.

Automatic tabs were used here, resulting in some of the tabs being placed in the corners of the internal cuts, making them harder to remove. Other than this, the parts came out really well.

Mirrored stainless steel nautilus gears test piece. Photos via 3D Printing Industry.

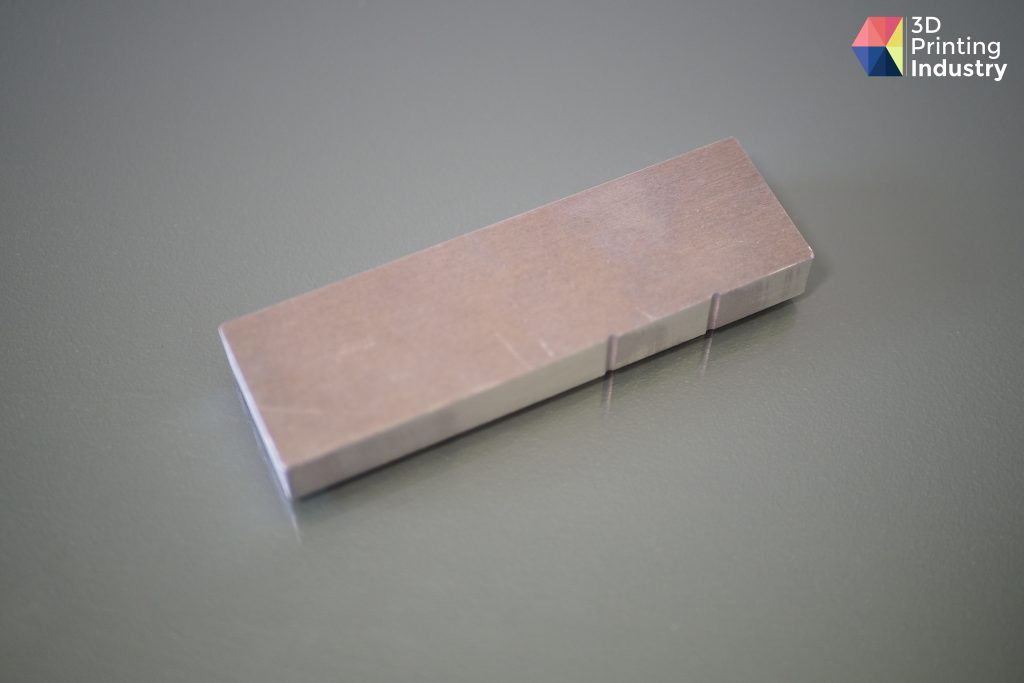

To test the WAZER’s ability to cut thick metals, we tasked the machine with cutting two reference blocks out of 12mm stainless steel and 6mm Delrin. The machine did run out of abrasive, and needed to be refilled when cutting the stainless steel block. During use, the WAZER will pause after an hour of cutting to prompt the refilling of the abrasive, with no guarantee that the second piercing will leave no marks following the restart.

Ultimately, we were very impressed with the WAZER’s ability to cut hard materials at such thicknesses, a capability usually reserved for larger industrial cutters.

Reference block test pieces. Photos via 3D Printing Industry.

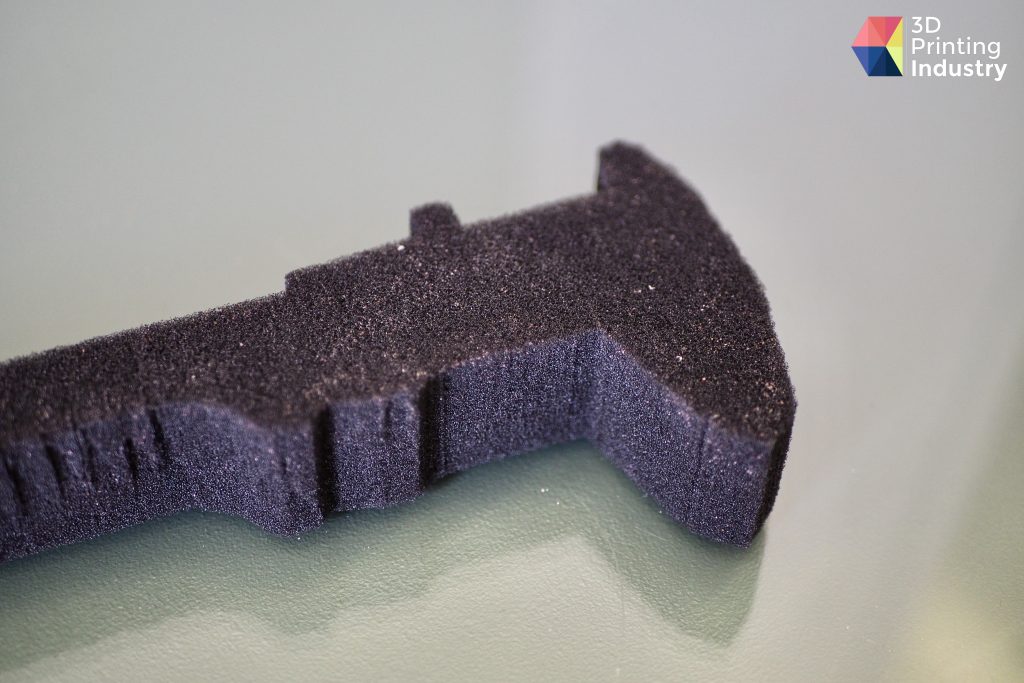

We also assessed its ability to cut soft and light materials, in the form of a foam caliper cut out. The WAZER easily cut through this material and left a very clean, uninterrupted cut.

Foam caliper test piece. Photos via 3D Printing Industry

Benchmarking the WAZER

To further assess the WAZER’s accuracy, we conducted a circular trajectory test, allowing us to identify any discrepancies between the X and Y axis.

Overall the cutter performed well, with some niggles. The Y-axis was mostly below the reference and the X-axis mostly above, indicating slight inaccuracies between the stepper motors on each axis. Additionally, the largest circle had the worst deviations on the X-axis, suggesting the machine has more trouble with large arcing movements, a known characteristic of belt-driven machines.

A water jet cutter is never going to match the accuracy of a laser cutter due to their different cutting methods. Thus, for most applications, these deviations are acceptable and should not impair the machines intended use. The standard deviation of circles 1 and 2 both fell below 0.5mm, whilst the mean difference of the x-axis (0.28mm) and Y-axis (0.37mm) are both good results.

With no visual deformities or misalignments found, the WAZER performed quite well during this test.

Circular trajectory test. Photos via 3D Printing Industry.

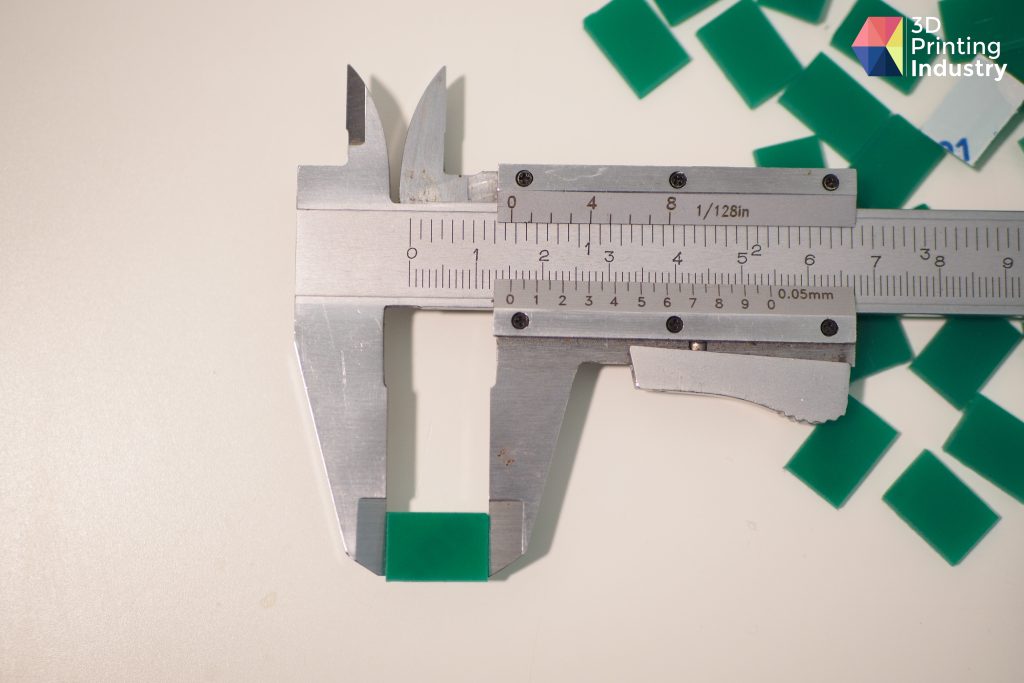

Finally, we conducted a repeatability test to gauge the WAZER’s capability of producing multiple parts with the same dimensions and tolerances.

These results were positive, with all measurements over the reference by an average of 0.37mm on the Y-axis and 0.14mm on the X-axis. Once again, the X-axis outperformed the Y-axis, suggesting that the Y-axis can overshoot its required distance by around 0.2mm in each direction.

The overall standard deviation on both axes was 0.085mm, below 0.1mm and a very positive result.

Repeatability test. Photos via 3D Printing Industry.

Our verdict:

There is definitely some room for improvement with the WAZER. For instance, whilst the WAM software is good, it does not offer the same level of customization and controls as other CNC softwares such as Lightburn (commonly used with laser cutters). Equally, being cloud-based and requiring strong WI-Fi, WAM is not accessible to those who may not possess strong internet connectivity.

However, the WAZER is ultimately a brilliantly designed and maintained machine, offering great value for a desktop water cutter. We found the machine easy to operate, with the WAM software and machine hardware all working as advertised. The support WAZER offers to its customers is particularly appealing.

The machine performed consistently well during our testing, possessing an ability to accurately cut both soft and incredibly hard materials. Admittedly, not all tests provided perfect results, with a definite learning curve when using the machine. Yet, after some perseverance, users will certainly have success with the WAZER.

A water jet cutter will never be as accurate as a laser cutter. However, what the WAZER may lack in accuracy, it more than makes up for in versatility, possessing an ability to cut most materials up to impressive thicknesses. The engineering behind the WAZER is very impressive, and it is easy to see why it has become such a successful product.

Subscribe to the 3D Printing Industry newsletter to ensure you keep up with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows the Wazer Water Jet Cutter. Photo via 3D Printing Industry.