Our engineering team has put together a hands-on review of the Sindoh 3DWOX 2X 3D printer.

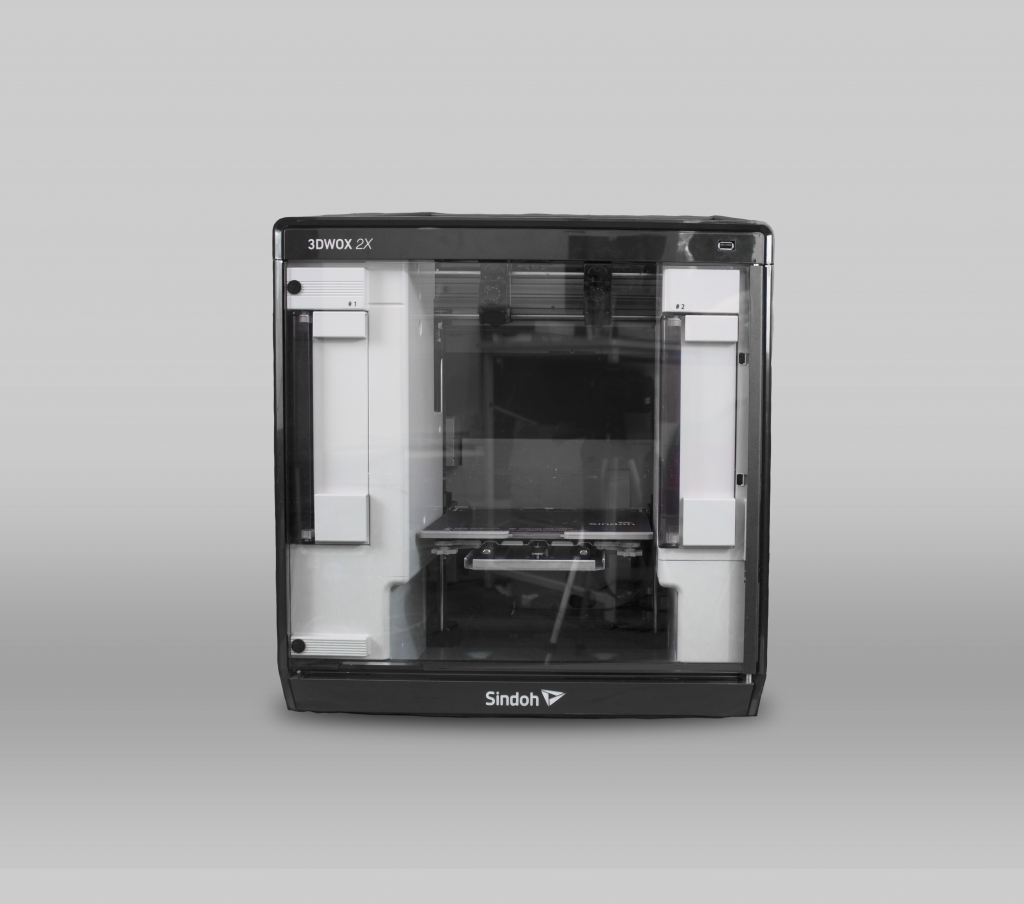

As the latest addition to its desktop range, the 3DWOX 2X from South Korean manufacturer Sindoh, responsible for the 3DWOX1, DP200 or DP201, is an Independent Dual Extrusion (IDEX) FFF 3D printer.

With over two years on the market, the company has branded the 3DWOX 2X as an easily-usable machine aimed both beginners and expert users. The 3D printer holds a maximum build size of 228x200x300mm, a heated bed up to 110°C, as well as a vocal guidance feature for trouble-shooting.

The following is an extensive review conducted by the 3D Printing Industry engineering team to evaluate the key claims of the 3DWOX 2X. The claims are as follows:

– Quality and accuracy

– Multi-material prints

– Ease of use / very user-friendly

– Wide range of materials

– Quiet operation

3DWOX 2X hardware: Print heads and cartridge

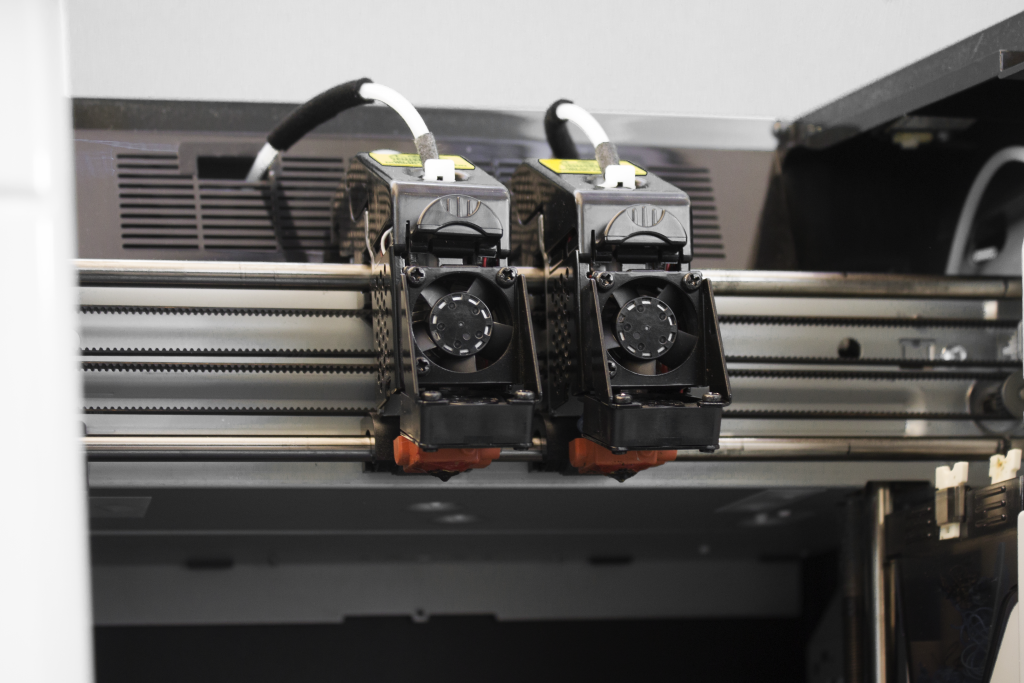

Unlike its predecessor, the 3DWOX1, the 3DWOX 2X is a dual extruder 3D printer. This allows for 2 different materials to be used in the same 3D printed model. The nozzles work interdependently, optimizing the production of the model, to create the multicolor, multi-material models. As a result, the weight of the print heads are reduced. Moreover, this system requires an accurate calibration which can be time consuming.

The print heads have a bowden extrusion system which puts the stepper motor supplying the filament away from the print heads. Furthermore, the filament is driven through a PTFE tube to the nozzle in the print head. This enables an increased print speed as well as precision as the heavy motor is not on the head – solidifying the claim of quality and accuracy.

Nevertheless, the drawback of this configuration is that it often reduces the quality of flexible filament prints as tolerances between the extruder gears can be too loose to be pushed toward the nozzle in the PTFE tube. In spite of this, the 3DWOX 2X handled the flexible filament well on TPU tests.

The 3DWOX 2X is equipped with a cartridge system for each loaded spool. This keeps the spool in the machine in a dry controlled area as the cartridge is closed off. Additionally, each spool has its own RFID chip which sends information such as the filament type, and the quantity used, to the printer. Third party filaments can also be used in the open materials mode.

Slicer and print setup

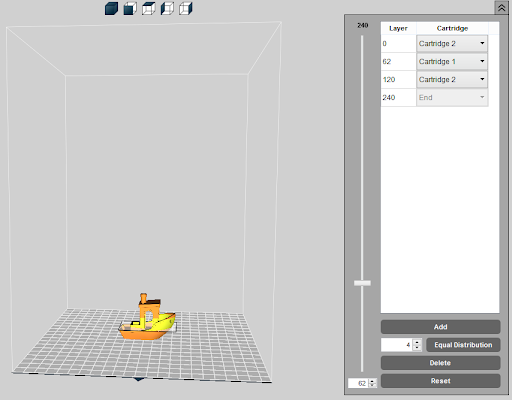

The 3DWOX 2X is compatible with several slicing softwares. For the purposes of this review, the 3DWOX Desktop Slicer was used due to its straightforward interface. The buttons on the right hand side of the screen allow users to reposition the model by moving it, rotating it, or scaling it. Two modes are available in this software, easy mode and advanced mode.

The engineering team found that the advanced mode is more suitable for those wanting to dive deeper into the parameters as it unlocks additional settings such as temperature control, retraction settings, print speeds for walls, infill, first layers, and outer contours.

Additionally, the ‘layer color’ option enables multi-color or multi-material models. Overall, the slicer was deemed to be very easy to use and the color/material distribution to the nozzles to be rather intuitive.

When setting up the 3DWOX 2X, the team loaded and unloaded the filament with ease thanks to the cartridge. The printer also automatically heats the nozzle and extrudes the filament to ensure the nozzle is primed and ready.

Print bed calibration, which is a semi-automatic process, took the team 5 minutes while XY calibration for the dual extruder system took 10 minutes as this step must be repeated a few times. Wi-Fi connection to the printer took no more than 2 minutes to complete. A USB drive can also be inserted directly into the 2X.

Single extruder print tests

Using Sindoh’s white PLA, several single extruder tests were conducted. The tests included a model of the 3D Benchy, a well-known benchmarking model. The 3D printed Benchy produced on the 3DWOX 2X showed good quality overall as the layers are not too visible. There were only a few strings visible between gaps as well as some artifacts which can be easily removed by hand.

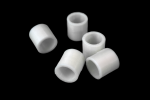

To test repeatability, 3 parts were all printed 5 times. As the reference dimensions are known from the original 3D model, the engineers were able to determine the discrepancy between measured dimensions and original dimensions, and the dispersion between them. The parts are printed in groups of 3 (1 square, 1 polygon, 1 tube).

To illustrate differences between the 3D printed models during the repeatability tests, the average or mean of the objects were calculated. The mean of differences is the mean of the differences between the measurements and the reference. It can be said that the difference between reference and measure under 0.1 deems the 3D printer as accurate. From the tested parts, the 3DWOX 2X was seen to be consistent and precise. It should also be noted that the printer operated rather quietly.

| Hole φ | Height | Width | Length | |

| Reference | 12 | 10.000 | 15 | 15 |

| Print 1 | 11.83 | 10.100 | 15.02 | 15.02 |

| Print 2 | 11.99 | 10.080 | 15.01 | 15.04 |

| Print 3 | 11.95 | 10.010 | 15.05 | 14.95 |

| Print 4 | 11.88 | 10.070 | 15.01 | 15.09 |

| Print 5 | 11.99 | 10.110 | 15.05 | 14.99 |

| Mean of differences | 0.07 | 0.07 | 0.03 | 0.04 |

| Mean of real values | 11.93 | 10.07 | 15.03 | 15.02 |

| Standard deviation (σ) | 0.07 | 0.04 | 0.02 | 0.05 |

| Mean + 3 x σ | 12.14 | 10.19 | 15.09 | 15.18 |

| Mean – 3 x σ | 11.72 | 9.96 | 14.97 | 14.86 |

The table above shows the square model measurements and calculations from the repeatability tests.

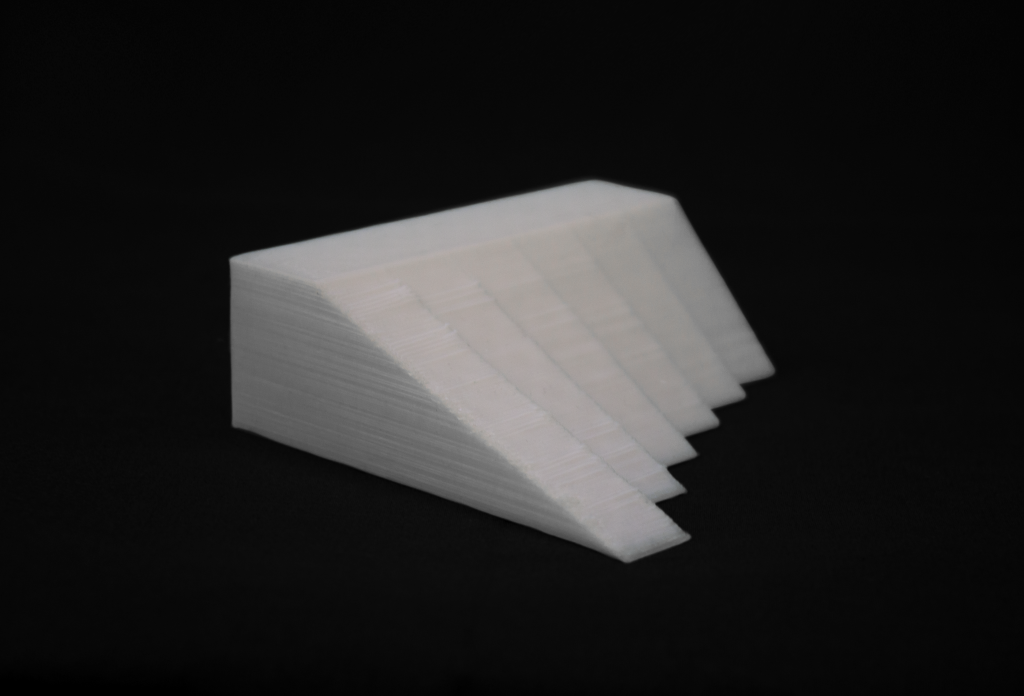

Overhang tests were performed to determine the maximum overhang angle possible without supports. The model used is composed of 6 walls printed in an increasing overhang configuration. The first overhang angle is 40°. The following ones are shifted by 5°until 65°.The overhangs under 45° were well printed, however, those above were not as smooth. The surface of the last overhang was inferior, according to the team, as they deemed the overhang limit to be 60°.

Bridging tests ranging from 5mm to 60mm were printed to evaluate the cooling ability of the printer. The team gathered that the quality remained up until the 15mm length bridge. A tower test successfully hit the 300mm height limit on the printer, while a circular trajectory test, evaluating the printer’s ability to print parts with circular sections, was generally satisfactory.

Retraction and small part tests were also conducted on the 3DWOX 2X. From the spiked model, retraction was proven to be very good as there was no stringing between the spikes. Following this, small nut and bolt models no more than 28mm were produced.They were shown to have good detail with no defects. The parts were then easily screwed together.

Dual extrusion and real application tests

To understand the capabilities of the interdependent nozzle system, multicolor models including a two-tone 3D Benchy, vase, digger and figurine were printed using blue and white PLA. The first trial of the Benchy was not successful due to a small discrepancy between the white and blue layers and the calibration. Nonetheless, after recalibration, the second trial was able to reduce the visibility of the shift between the layers.

A 3D Benchy and moving crane were also printed simultaneously to test the quality of the models. Both prints were considered to be printed accurately, particularly due to the successfully produced joints and the minimal gaps between parts, allowing for easy movement on the articulated digger model.

TPU and PVA supports

Moving on to TPU, the team aimed to test the printer’s ability to process flexible filaments. At a nozzle temperature of 240°C and bed temperature of 70°C, the team printed a smooth phone case with absolutely no stringing. This was a pleasant surprise, as printing flexible filament on a bowden configuration is not often an easy process.

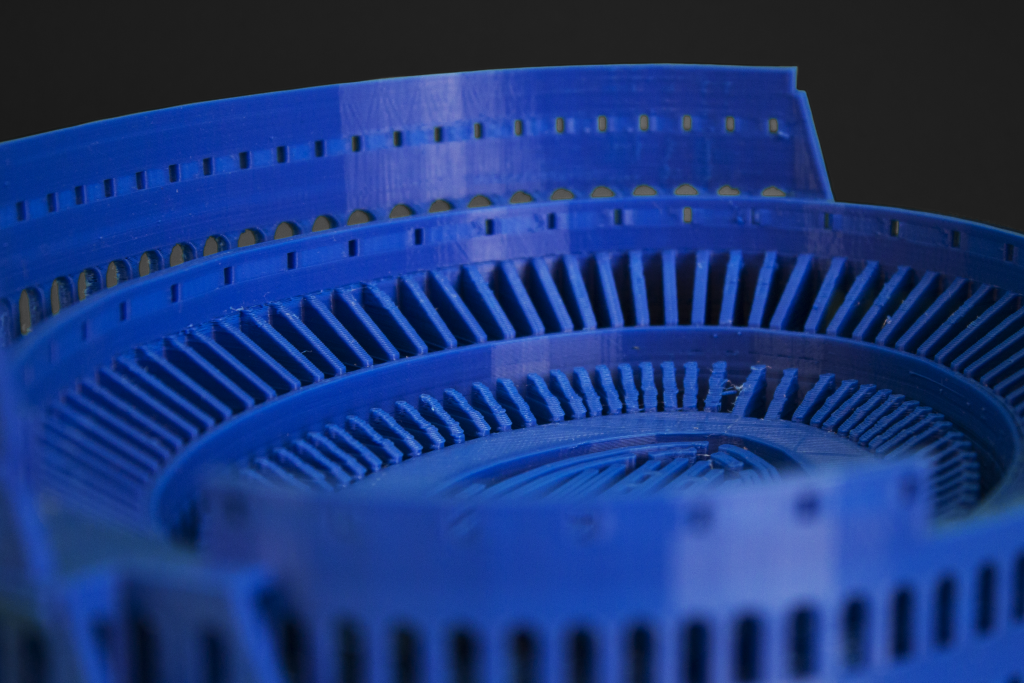

The 3DWOX 2X’s ability to print models with PVA support was also tested. High detail models with lots of overhangs were produced using PLA. The final model was well printed showing no shift between the supports and the printed parts. The team found that the supports easily dissolved in warm water resulting in clean prints. The dual nozzles are very accurate when it comes to differentiating support layers from parts of the model, this can be observed in the image below depicting the accuracy on the small openings.

A straightforward, competent 3D printer

From our extensive review, the team found the Sindoh 3DWOX 2X 3D printer to be a reliable, user-friendly, system capable of manufacturing large and small models with very few defects. Its dual extrusion system also enables multi-colour parts or PVA supported parts, great for detailed models and useable parts.

Nonetheless, it was noted that the 3DWOX 2X could improve with a more precise method for XY calibration. Moreover, after having done the calibration 2 or 3 times, the print heads are still not always perfectly calibrated. A “mirror” mode would also increase the system’s capabilities given its IDEX system. It is to be noted that some filament combinations are not possible. For example PLA loaded in the first print head and TPU in the second one. In addition, the size of the workspace is small when compared to the 3D printer’s overall footprint.

The Sindoh 3DWOX 2X is a very competent machine that allow users to print with confidence. The cartridge system improves the accessibility of materials as various filaments, including third party filaments, can be handled. An office environment would be suitable for this 3D printer due to its quiet operation and its vocal guidance also facilitates the use of the machine for early users.

The 3DWOX 2X is available from authorized resellers around the globe.

For in-depth reviews and other news, subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Find talent for a project, or advance your career in 3D printing – join 3D Printing Jobs to apply and advertise.

Featured image shows the 3DWOX 2X 3D printer. All photos by 3D Printing Industry.