Earlier in the week, researchers from the Australia-based Queensland University of Technology unveiled some major developments in the global fight against cancer. The research team has developed a 3D printable hydrogel, which could soon provide cancer patients with quick and personalized tumor treatment by enabling multiple, simultaneous tests to find the proper therapeutic path to target a particular tumor. By utilizing the same type of hydrogel biomaterial used by researchers across the globe, the QUT research team was able to reengineer the material into 3D tumor microenvironments.

With this breakthrough, the gelatin methacryloyl-based hydrogel could potentially be used as a bioink for 3D printed microenvironments or tumor models, which will enable researchers to directly test different anti-cancer drugs on the tumor cells. The hydrogel itself can mimic a wide-range of tissues from the body, from firm cartilage to soft breast tissue, and thus can be used to create models for all types of cancer, as well as stem cell and tissue engineering research. The QUT researchers are not just able to create 3D tumor microenvironments from the newly developed hydrogel, but are also able to do so on a very large scale at a very low price, which lends even more credence to this as a medical breakthrough.

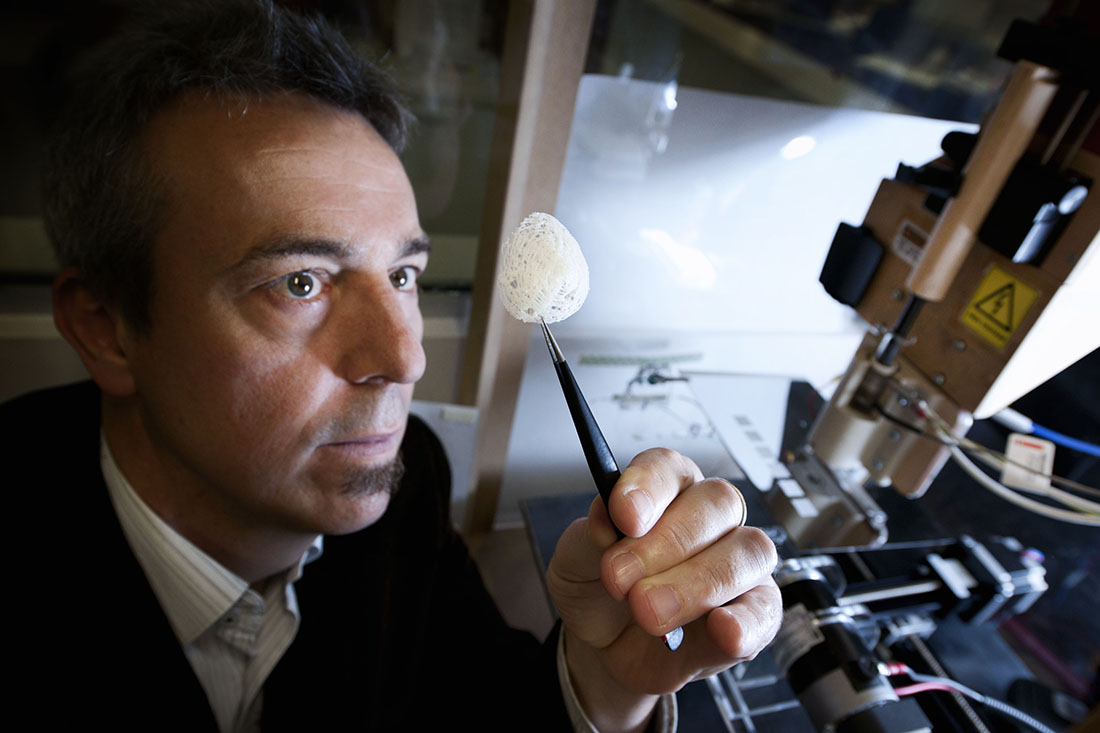

“Our big breakthrough is we can produce this high-quality material on a very large scale inexpensively,” said Dr. Dietmar W. Hutmacher, a professor from QUT’s Institute of Health and Biomedical Innovation. “It is highly reproducible which means we have been able to produce this hydrogel hundreds of times, not just once or twice in the lab, so researchers worldwide will be able to create it.”

In a time where most cancer treatments involve chemotherapy, which affects and hinders every cell in the body, the potential that this hydrogel has for personalized treatment could someday change the way tumors are treated. When facing the extremely time-sensitive issue of cancer treatment, every minute counts, and this new hydrogel could save doctors and their patients weeks in the search for the optimal personalized treatment. “Instead of the sometimes hit and miss chemotherapy that affects every cell in the body this will allow us to test different anti-cancer drugs and different combinations of them all at once so that we can pinpoint an individualized treatment that will hit only the cancer cells,” said Dr. Hutmacher. “It will cut the process of finding a personalized treatment for each patient down to a week or two.”

Alongside Dr. Hutmacher, who led the Biofabrication Research project, the QUT Institute of Health and Biomedical Innovation research team included Dr Daniela Loessner, Associate Professor Travis Klein and PhD student Christoph Meinert. The team will be releasing a full study on the function, preparation, and use of the newly developed hydrogel to create tumor-mimicking modular tissue platforms. For Dr. Hutmacher, their research is just the beginning of a bright future involving biofabrication in medicine: “Biofabrication is the future of medicine. It is a multidisciplinary area of research that requires an understanding of chemistry, physics, biology, medicine, robotics and computer science and we welcome graduates from any of these fields to apply for the master degree.”