The 2021 3D Printing Industry Awards shortlists are now open for voting until the 20th of October. Cast your votes here.

3D printer manufacturer Prusa has announced the launch of its new Prusa Pro Automated Farm System (AFS).

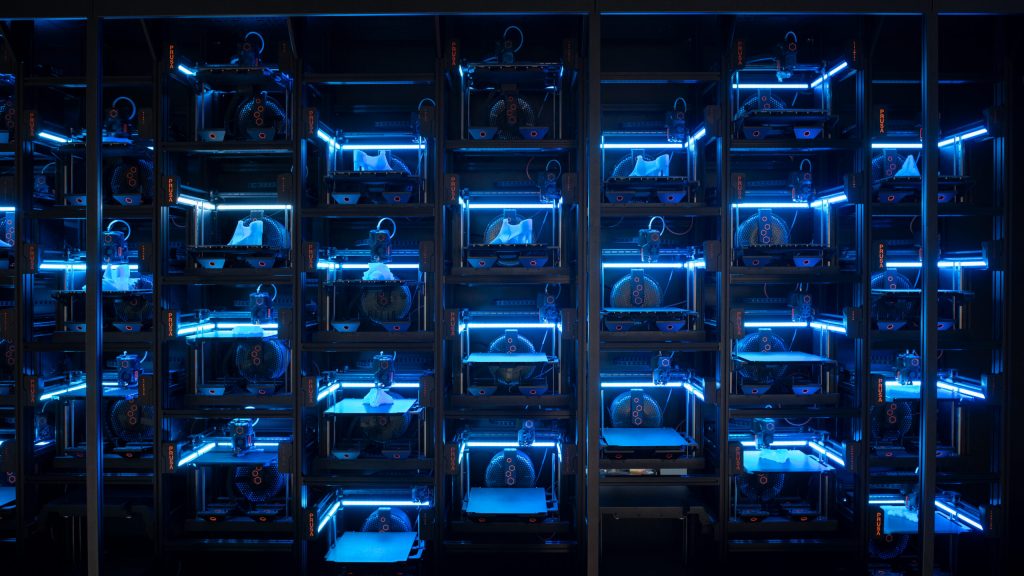

The company’s latest innovation is a modular print farm aimed at large campus universities, engineering firms, spare part manufacturers, on-demand 3D printing service bureaus, and anyone else seeking fully automated small batch production. Prusa has already developed a fully functional prototype comprising 34 new CoreXY Original Prusa 3D printers, which is currently being showcased in the Czech pavilion at Expo 2020 in Dubai, a World Expo set to run until 31 March 2022.

On a side note, the Dubai Expo also features a 3D printed replica of Michelangelo’s David, made using 3D scanning and resin 3D printing technology. The organizers of the event have reportedly covered the 17-foot statue’s private parts up in an attempt to maintain a PG rating, despite the original proudly showing off all of its appendages in Florence.

Towards automated additive manufacturing

Founded in 2012 by Josef Průša, Prusa Research is well-known in the 3D printing community for its extensive portfolio of desktop machines catering to both hobbyists and professionals. The firm already runs a massive 24/7 print farm of 600 3D printers at its HQ in Prague, but this is maintained by an entire team of farm operators.

Josef Průša said, “We always wanted to automate the production, yet there has never been the opportunity to do it. This changed about three years ago. We were approached with the idea to represent Czechia at Dubai’s EXPO 2020 – provided that we would have something ‘next-gen’ to show. It was the right opportunity to dive headfirst into our plans for our new 3D printing farm.”

Prusa assembled a new team to develop this automated print farm and three years later, the Prusa Pro AFS has made its debut in Dubai.

The Prusa Pro AFS

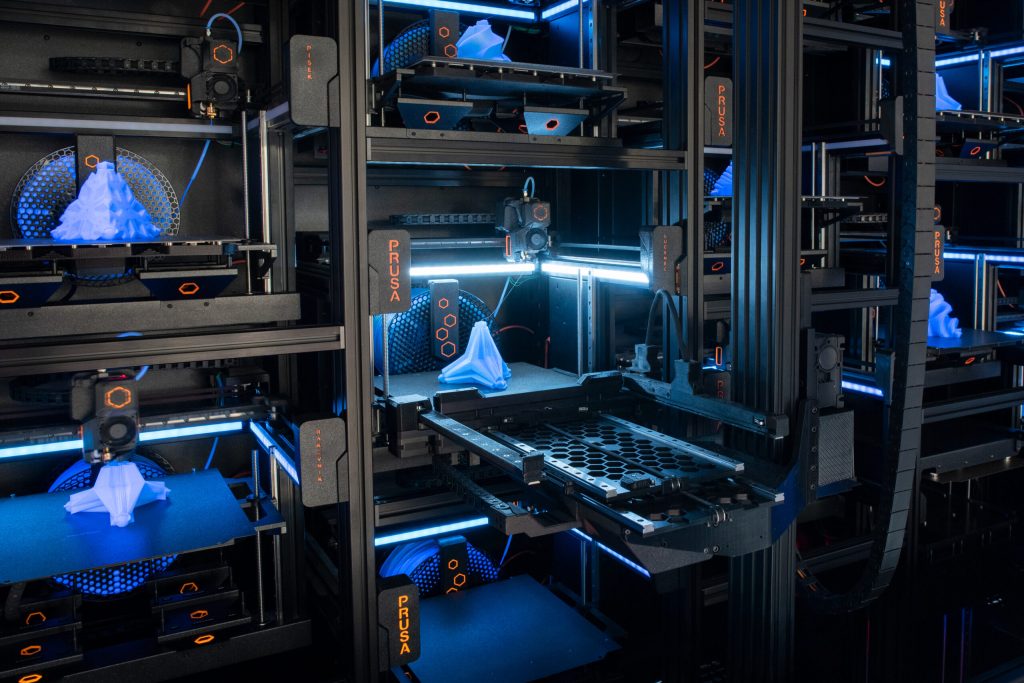

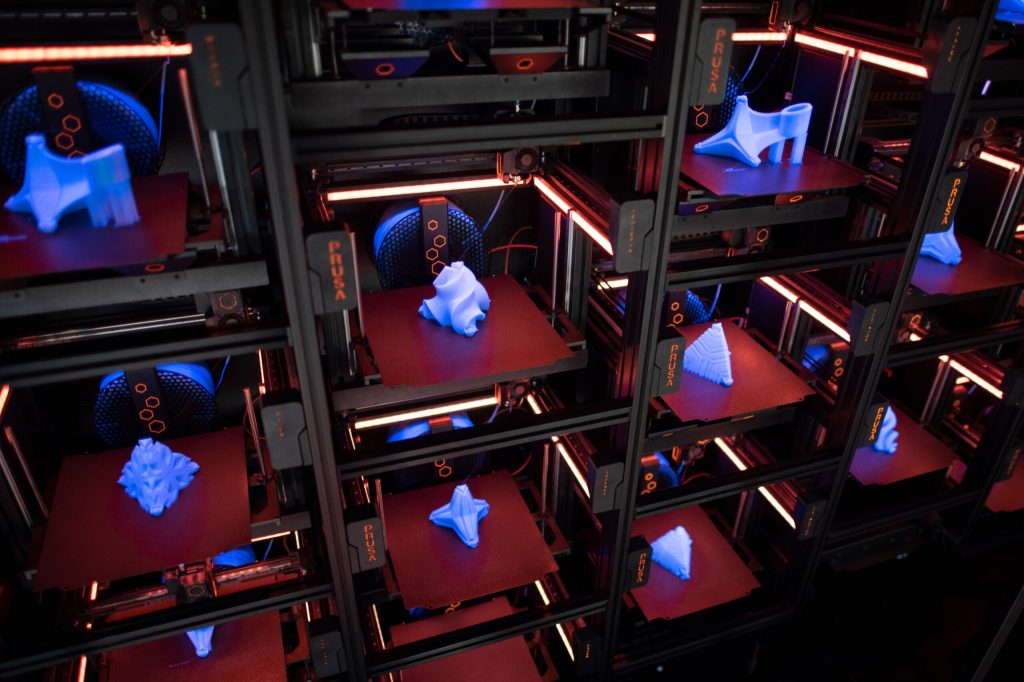

The AFS is made up of 34 purpose-built Prusa 3D printers, specially developed farm management software, and an automatic part collection and delivery system. In a bid to make the system more compact, the company designed a cube-shaped frame for each printer module. Much like a server rack, these modules can be hot-swapped, meaning printers can simply be slid out when they need to be serviced and a new one can be installed in minutes.

Although the prototype happens to feature 34 printers, the print farm itself is actually designed to be scalable and the number of printers isn’t fixed. Prusa also intends to develop several options for unloading parts too, beyond just the simple two-bin system being showcased at Expo 2020.

The newly developed software being used to control Prusa Pro AFS is called Prusa Connect. Designed for comprehensive print farm control, the program offers a number of intelligent functions to truly automate the 3D printing workflow. When a model is selected for printing, Prusa Connect will automatically find the best printer for the job, all while keeping track of active print jobs, statistics, remaining print times, and other key parameters.

Once a build is complete, the control software then sends a mechanical arm to remove the print sheet and place it in the collecting bay where the part is detached and dropped off in the collection bin. The arm then returns the sheet to the printer to start the next print.

The next step for Prusa is to stress-test the AFS at its HQ over a period of several months. With plans to deliver the first units within the next year, the company expects its print farm to cost approximately $3000 per printer (+ service contracts).

Just last month, Prusa also launched the latest version of its open-source slicing software, the second alpha release of PrusaSlicer 2.4.0. Building on 2.4.0 alpha one, this latest release brings with it several new features and upgrades to make the pre-printing workflow faster and more efficient. The software has also fixed a whole host of bugs that were found by users, making for a cleaner 3D printing experience.

Earlier this summer, the company announced the launch of a new resin-based LCD 3D printer called the SL1S Speed. Intended as a successor to the company’s debut MSLA system, the SL1, the new and improved SL1S Speed comes complete with a plethora of significant upgrades. As well as a 25% larger print area, the system offers a print speed three times faster than its younger sibling, with cures times as low as 1.4s per layer.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the new Prusa Pro Automated Farm System (AFS). Photo via Prusa.