Commercially available 3D printers may not be capable of 3D printing your next smartphone, but that doesn’t mean that researchers aren’t working on it. A team of scientists at Princeton University have made a breakthrough in the 3D printing of functional electronic components, according to Nanowerk. By creating their own 3D printer and carefully choosing a number of five different materials, the team was able to 3D print functioning quantum dot LED lights.

Published in Nano Letters, the team’s report, “3D Printed Quantum Dot Light-Emitting Diodes”, outlines the process by which the team was able to, layer by layer, combine five unique materials into a single LED. Assistant professor of mechanical and aerospace engineering at Princeton University, Michael McAlpine, explains to Nanowerk, “The big push in 3D printing these days is to try to print two or more polymers at once. In our latest research, we go way beyond that. We show that we can print interwoven structures of quantum dots, polymers, metal nanoparticles, etc, to create the first fully 3D printed LEDs, in which every component is 3D printed.”

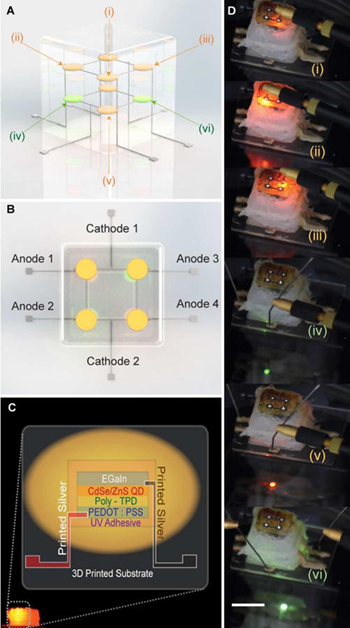

To do so, McAlpine et al. chose electrodes, semiconductors, and polymers that could both be printable and had the properties necessary for the project. They then dissolved the materials in orthogonal solvents, to ensure that each layer of material does not damage the ones beneath it. The materials are finally dispensed via a computer-controlled device fulfilling a CAD design. With this method, the team printed 2 x 2 x 2 arrays of quantum dot LEDs. By changing the size of the quantum dots used in the experiment, the researchers were able to determine their color, either green or orange, in this case.

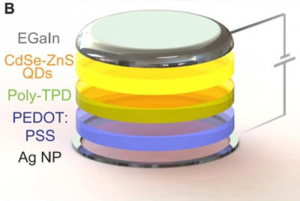

McAlpine’s graduate student and first author on the paper, Yong Lin Kong, elaborates, “Specifically, we demonstrate the seamless interweaving of 1) emissive semiconducting inorganic nanoparticles; 2) an elastomeric matrix; 3) organic polymers as charge transport layers; 4) solid and liquid metal leads; and 5) a UV-adhesive transparent substrate layer.” Kong says, “Using this approach, we can create unique structures, such as 2x2x2 arrays of LEDs, in which the electrical wiring runs horizontal and vertical, to create a multi-color 3D stack of LEDs.” And, according to Kong, “The printed QLEDs exhibit excellent performance characteristics.”

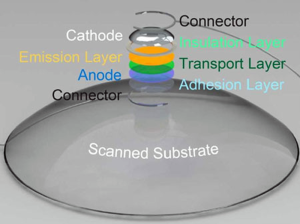

To further demonstrate the possibilities of their process, the Princeton researchers were even able to print the QLEDs onto a contact lens. The team first 3D scanned the lens and used a subsequent CAD model to instruct their printer to deposit the layers of the QLEDs onto the lens’s curved surface. Kong explains, “We also use 3D scanning to carefully scan a contact lens and store the specific topology of that lens, and then alter our 3D printing to adjust to that topology, allowing us to conformally 3D print LEDs on a contact lens. This may have use in electronic contact lens or bionic eye applications in the future.”

Printing onto curved surfaces opens the process up to free-form fabrication onto objects, leading to bionic devices and prosthetic implants. McAlpine suggests that they may be able to 3D print other complex devices, saying, “We anticipate that this general strategy can be expanded to 3D print other classes of active devices, such as MEMS devices, transistors, solar cells, and photodiodes. Our results suggest a number of exciting applications, including the generation of geometrically tailored devices containing LEDs and multimodal sensors to provide a new tool for optogenetics for studying neural circuitry.”

Before they can pull this off, the team will be pursuing further research, improving the 3D printer’s resolution to create even smaller devices, while also enhancing the performance and yield of the objects made, and looking into 3D printing functional blocks, such as semiconductors or plasmonic and ferroelectric devices. Kong concludes, “This work outlines an exciting breakthrough that enables the direct printing of functional, embedded, active 3D nanoelectronics using only a 3D printer. Indeed, this is the first time to our knowledge that semiconducting nanoparticles have been 3D printed, and the first time that such a broad array of diverse functional materials have been fully interwoven entirely using a 3D printer.”

To read the complete study, head over to Nano Letters!