3D Printing Industry has arrived in Birmingham, UK, once again for the latest edition of the TCT Show.

The design-to-manufacturing event at the NEC is host to an abundance of 3D printing equipment, including new several new systems. As a returning attendee, the landscape is noticeably different from the desktop 3D printer-friendly machinery at TCT Show 2018.

Among the various product launches, expected to total 35 by the end of the show, FFF/FDM systems continue to covet “industrial” environments. Speaking with Ultimaker, Intamsys, and Zortrax, 3D Printing Industry gained insight on the changing demands of the market.

Ultimaker professionalizes FFF/FDM

Starting off the first day of TCT by debuting the Ultimaker S3 and the Ultimaker S5 Pro Bundle, Ultimaker has further recognized the production capabilities of its FFF/FDM systems. The S5 Bundle, in particular, which features an Air Manager for filtration and build control, and a Material Station for storing and feeding filaments, is targetting low-volume production applications.

Speaking with the company’s CMO, Nuno Campos, the altering needs of those using 3D printing is emphasized. “We have demands from customers like Heineken who want to have continuous production – a machine where users don’t have to interact as much. The launch of these products are a result.”

“What we see is our machines being used by actual enterprises, be it for tooling or spare parts, hence the recent rebrand. We had customers saying ‘what is this on the side, it doesn’t fit?’ when referring to the robot logo, so we decided to become more professional and less playful.”

“Even though it is a noticeable change, it’s a natural growth that will not leave the makers behind but also enhance their 3D printing options. It’s not one or the other,” added Campos.

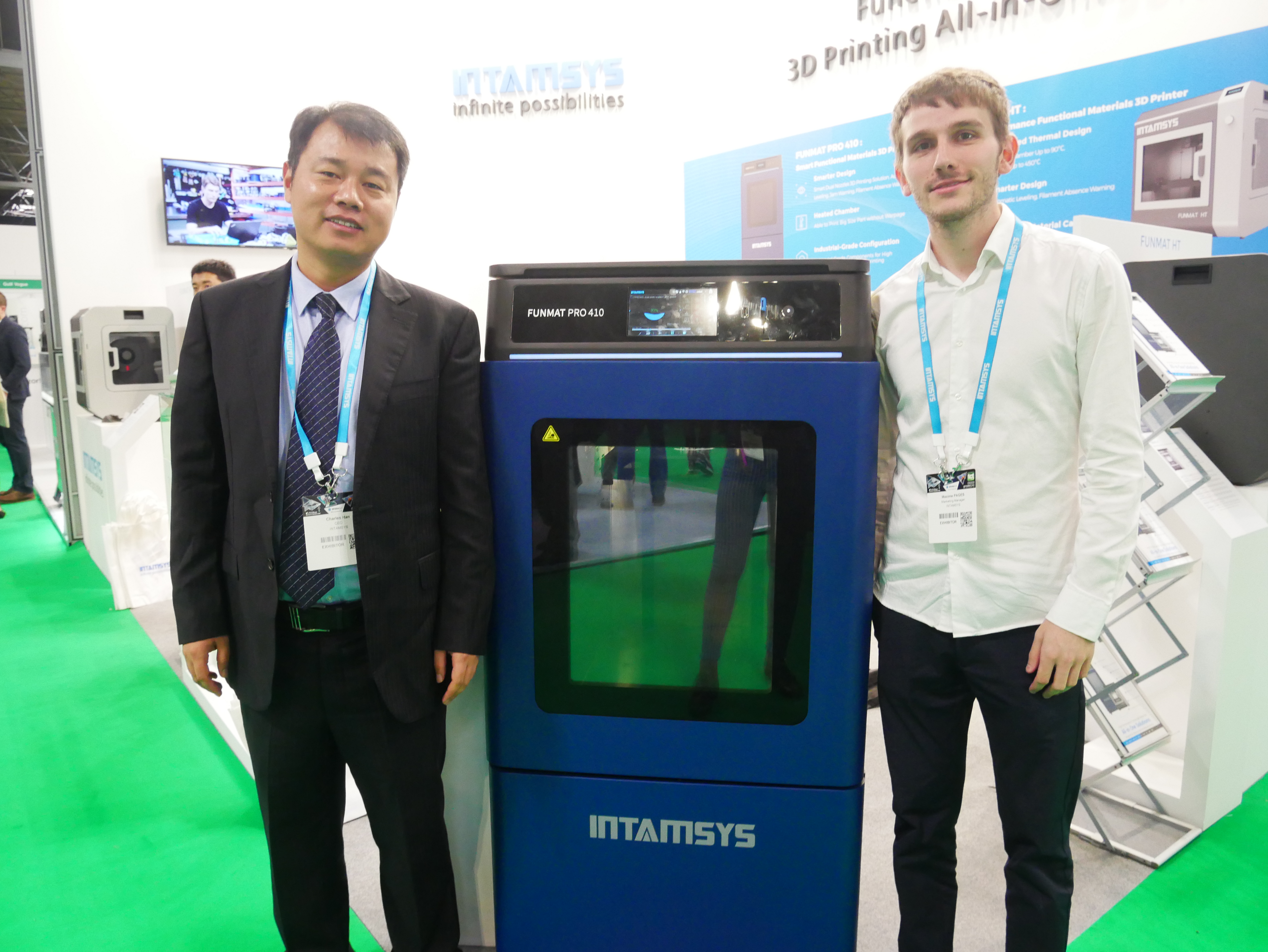

Intamsys addresses experienced users

Also making its debut is the FUNMAT PRO 410 industrial 3D printer, which was displayed with the recently released Enhanced FUNMAT HT from Intamsys. Built with high-temperature materials in mind, these systems are aimed for users who know what functions they need from a 3D printed part, according to Charles Han, CEO of Intamsys.

Han continues, “We are getting customers with experience in 3D printing, and with that comes the increase of demand for our systems to address industrial applications. There are requests for bigger, better quality prints that can fulfill a task, which is what the 410 addresses. Of course, entry-level users can still create models with the HT, but for those wanting uniform production for strong tools and such, the 410 is the option.”

Zortrax and its first industrial FFF/FDM 3D printer

Further emphasizing the trend is Zortrax and its first industrial FFF/FDM system, the Endureal. Unlike the company’s M300 series which promotes “large-format models made with a desktop-sized 3D printer”, this new machine also addresses challenging materials such as PEEK for automotive, aerospace, and medical applications.

Anna Wójcik, Senior Key Accounts Manager at Zortrax, told 3D printing Industry, “The Endureal, as you can see, is fit for production. We’ll be adding more to it soon, but we wanted to please our customers who had been asking for the capabilities to print materials like PEEK.”

“Over the past few years, people have become more educated and more confident with FDM printers or LPD in our technology. I believe this has caused the popularity of larger, more industrial systems because they see what additive manufacturing can do, and they want to explore more of that in a professional setting.”

Nonetheless, Zortrax remains committed to UV LCD 3D printers, which continue to have significance in the medical and dental sectors. Wójcik continues, “The market truly dictates the direction of hardware. Our LCD 3D printers are highly requested by dentists and jewelry makers because they need more precise details in what they make.

“By what I can see, the main differences within the industry is that people know what they need from additive manufacturing and we must adapt to suit those needs.”

For live updates from TCT Show 2019, subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook. Seeking jobs in engineering? Make your profile on 3D Printing Jobs, or advertise to find experts in your area.

Featured image shows TCT Show 2019 signage. Photo by Tia Vialva.