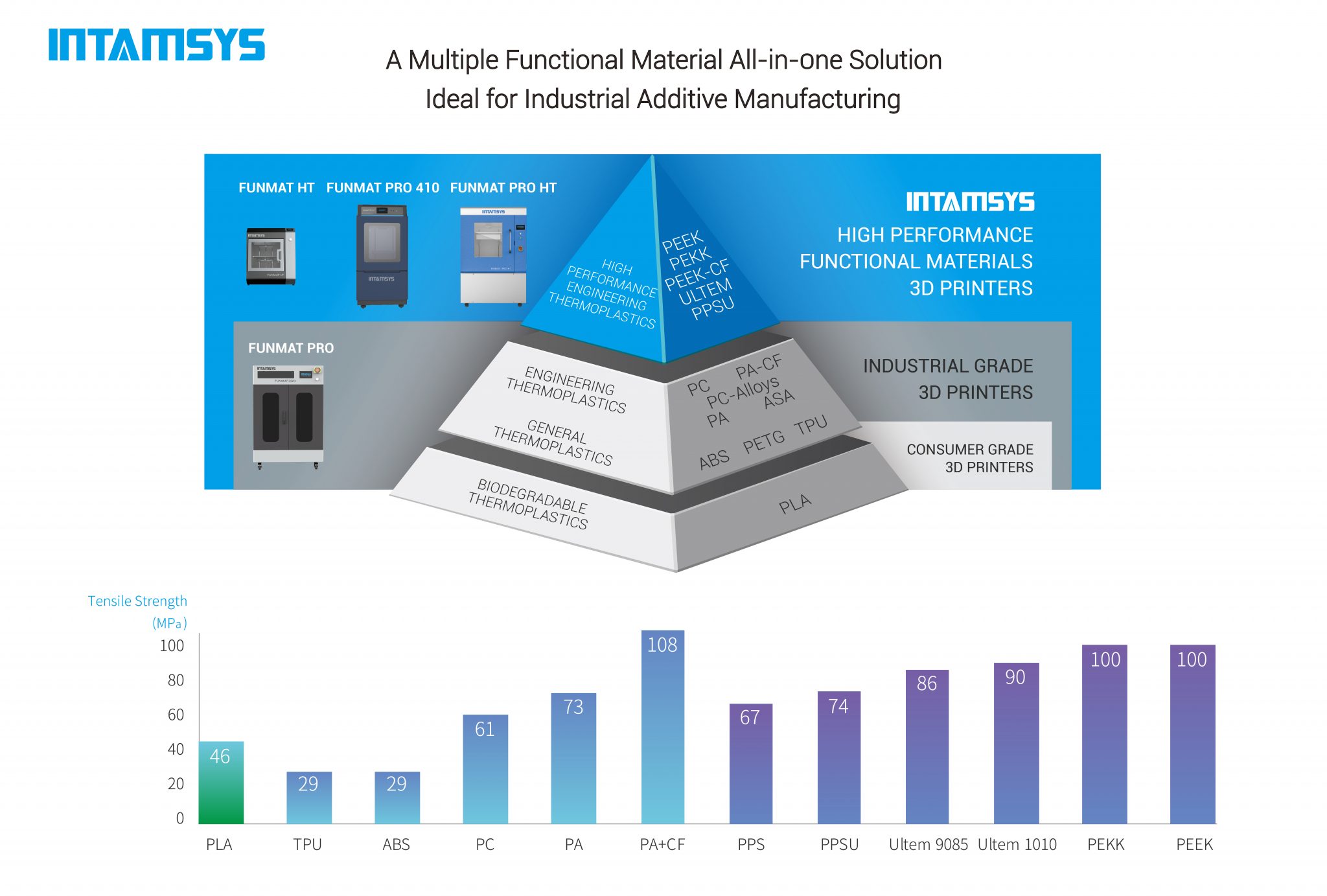

High performance 3D printer materials manufacturer INTAMSYS, headquartered in Shanghai, has released the FUNMAT PRO 410. Termed an “all-in-one” solution, the FUNMAT PRO 410 is designed to work with a diverse selection of materials. Many filaments, from low temperature PLA, through to engineering-grade and high performance polymers like PC, PA, PA+CF and PC, PA, PA+CF , can be processed by the system, a capability that remains one of INTAMSYS’ key differentiators in the current market.

“Since we launched our first high performance functional materials 3D printer FUNMAT HT two years ago in Formnext, a lot of customers have been attracted by its excellent multiple functional materials 3D printing capabilities and its affordable price,” says Charles Han, CEO of INTAMSYS.

“As more and more customers knew the potential behind FUNMAT HT, they requested with higher requirements, such as a bigger print size, easier to use, higher printing speed etc.. FUNMAT PRO 410 is the right answer to our customer requirements.”

Connected, versatile and user-friendly

Like its predecessor the FUNMAT HT, the FUNMAT PRO 410 was launched to the public at the annual Formnext exhibition in Frankfurt. It is a dual extrusion system, relying on one nozzle to 3D print build material (e.g. PEKK, Nylon, TPU) and the other to provide relevant supports (e.g. PVA).

It has a build volume of 305 x 305 x 406 mm, and a maximum print speed of 300 mm/s (dependent upon material). A compact system, the FUNMAT PRO 410 has been designed to blend in with typical office environments, and keeps a low operating volume.

For the optimal user experience, the system has a number of features aimed at ease of use. It is installed with automatic bed levelling, print recovery after power-outage, warning notifications for filament jam or absence and 7 inch smart panel for comfortable control. Connectivity has also been made accessible, allowing the user to opt for operation via Wifi, internet application or USB.

According to the company, “No matter how experienced you are, you can quickly master our FUNMAT PRO 410.”

Low volume production and functional prototyping

With its material versatility, the FUNMAT PRO 410 3D printer is ideally suited to low volume production and functional prototyping. Chinese rechargeable battery supplier BYD is an experienced user of INTAMSYS’ FUNMAT 3D printers. According to Roger Wang business development director at BYD, “INTAMSYS solutions bring us strong tools to deal with jigs and fixtures application in our production line because of their FUNMAT series printer’s strong multiple functional materials capabilities.”

Wang says that a variety of materials, such as ABS, Nylon, Carbon Fiber and PEEK are required on BYD’s production line, and so the INTAMSYS range of 3D printers has become an “all-in-one solution to us.”

INTAMSYS has started accepting pre-orders of the FUNMAT PRO 410, and the first batch printers are to be shipped January 2019. Retail price for the FUNMAT PRO 410 starts from $20,000 USD.

FUNMAT PRO 410 full technical specifications

| Machine dimensions | 720 x 620 x 1460 mm |

| Weight | 200kg |

| Operation temperature | 15 – 30°C |

| Storage temperature | 0 -30°C |

| Power input | 220V/9A |

| Power consumption | 2000W |

| Connectivity | Wifi, internet, USB |

| Touch screen | 7-inch smart touch panel |

| Safety | EN60950 |

| Regulatory compliance | CE |

| Printing technology | Fused filament fabrication (FFF) |

| Build volume | 305 x 305 x 406 mm |

| Layer thickness | 50 µm, 0.1 mm, 0.15 mm, 0.2 mm, 0.3mm |

| Nozzles | Dual |

| Print speed | 300 mm/s |

| Nozzle diameter | 0.25 mm, 0.4 mm, 0.5 mm, 0.6 mm, 0.8 mm, 1.2 mm |

| Nozzle cleaning | Automatic |

| Filament diameter | 1.75 mm |

| Compatible materials | PEEK, PEKK, PEI, PPSU, PC, PLA, PVA, TPU, Carbon Fiber, Nylon and more. |

| Camera | Yes |

| Leveling | Automatic |

| Extrusion temperature | 450°C |

| Platform temperature | 160°C |

| Chamber temperature | 90°C |

| Smart monitor & control | Filament jam & absence warning, power failure recovery |

| Build plate | Glass, ceramic |

| Filament chamber | Heated dry box |

| XY resolution | 0.016 mm |

| Z resolution | 0.0016 mm |

| Slicing software | IntamSuit, Simplify 3D, Cura |

| Supported file types | .stl, .obj |

| Operating system | Windows |

For all of the latest additive manufacturing news and releases, subscribe to our free newsletter, follow us on Twitter and like us on Facebook. Join 3D Printing Jobs now to search for the next step in your career.

Featured image shows the FUNMAT PRO 410 3D printer. Image via INTAMSYS