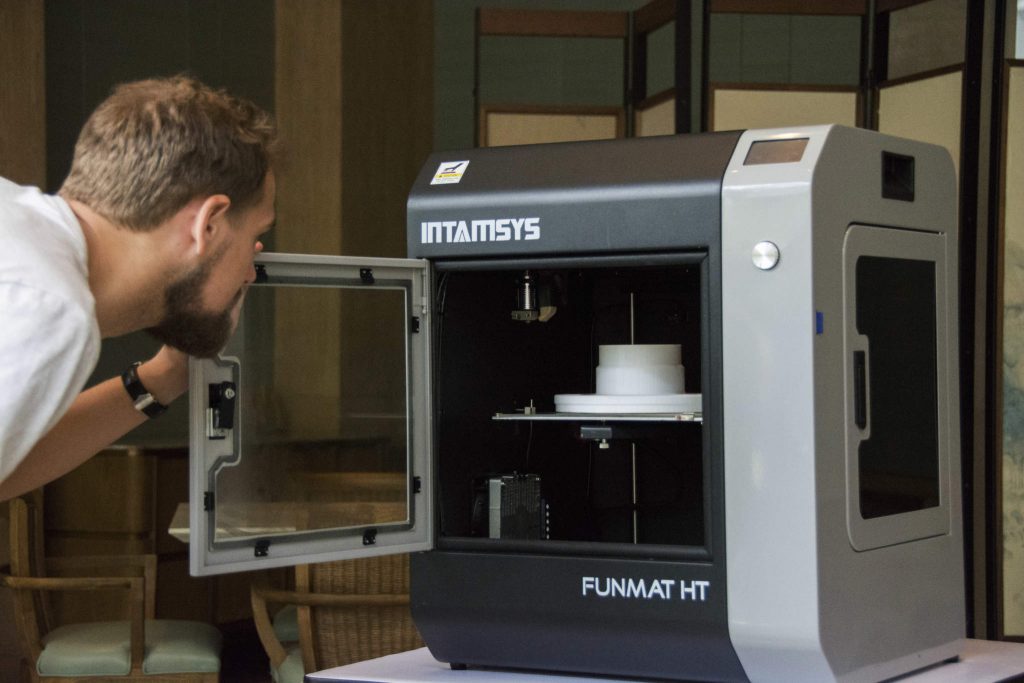

Professional 3D printer manufacturer INTAMSYS, headquartered in Shanghai, has released the FUNMAT HT desktop 3D printer. Capable of 3D printing high temperature materials like PEEK, Ultem and PPSU, the FUNMAT HT opens up access to industrial plastics for a fraction of the cost of typical high performance machines.

We take a closer look at one of the first affordable desktop 3D printers to use higher grade functional engineering materials. The full details are available here.

Low-budget access to 3D printing for engineers

First launched at CES 2017, the FUNMAT HT is a machine devised for engineering firms to test the potential of 3D printing at high temperatures. It is distributed with two interchangeable hot ends, one high temp and one low temp, preventing material contamination that can result in the failed performance of a print.

3D printing up to 450℃

The high temperature hot end is capable of reaching temperatures up to 450°C, which in turn opens up the mechanical and resistant properties possible.

PEEK is a medical-grade plastic that, for its mechanical robustness, is also in use in the aerospace industry and the standard for interior parts of the Airbus A350 XWB commercial airplane. And PPSU, another material compatible with the FUNMAT HT, is chemical resistant and suited for automotive, aerospace, and plumbing applications.

The lower temperature hot end, by comparison, is capable of working with standard 3D printer materials such as PLA and ABS. This allows for a versatile use of the machine, switching between potential end-user parts and prototyping.

High performance at a low price

In order to produce such high performance parts, the 3D printer also has a heated bed, capable of reaching 160°C, and a conditioned build chamber with ambient temperatures up to 90°C. The FUNMAT HT is also installed with a optimized cooling fan to maintain the quality of an object throughout printing.

The 3D printer retails at $5,000, approximately a $10,000 reduction on the price of other 3D printers with such material versatility. A FUNMAT PRO HT model will be available later this year with a bigger build volume of 450mm x 450 mm x 600mm, in comparison to the base model’s 260mm x 260mm x 260mm.

More technical specifications for the INTAMSYS FUNMAT HT can be found below.

Stay up to date with the latest 3D printer releases and news by subscribing to our newsletter and following us on twitter and Facebook.

Technical specifications

Technology – Fused Filament Fabrication (FFF)

Build volume – 260mm x 260mm x 260mm

Position accuracy – 12.5μm x 12.5μm x 1.25μm (X x Y x Z)

Build platform – Aluminium plate & high borosilicate glass

Supported files – STL, OBJ

Printing specifications

Layer thickness – 0.05 – 0.3mm

Heated bed maximum temperature – 160°C

High temperature extruder maximum temperature – 450°C

Build chamber atmospheric temperature – 90°C

Compatible materials – PEEK, ULTEM, PPSU, PLA, ABS, Nylon (PA)< Carbon Fiber, TPU, PC

Filament diameter – 1.75mm

The INTAMSYS FUNMAT HT 3D printer can be seen in action in London, UK.

Featured image: The FUNMAT HT 3D printer. Photo via INTAMSYS